Solving High Density Data Center Challenges with Rear Door Heat Exchangers (RDHx)

As demand for computational power accelerates, high-density data centers have become the backbone of modern IT infrastructure. Yet with greater rack density comes a formidable challenge — how to effectively manage the thermal output of densely packed servers. Traditional cooling strategies, such as CRAC units and underfloor air distribution, are increasingly inadequate. The shift toward rack-level cooling has led to the rise of the Rear Door Heat Exchanger (RDHx) as a pivotal technology in next-generation thermal management. RDHx cooling for high density racks is seen as the future of data center cooling.

Understanding RDHx: Cooling at the Source

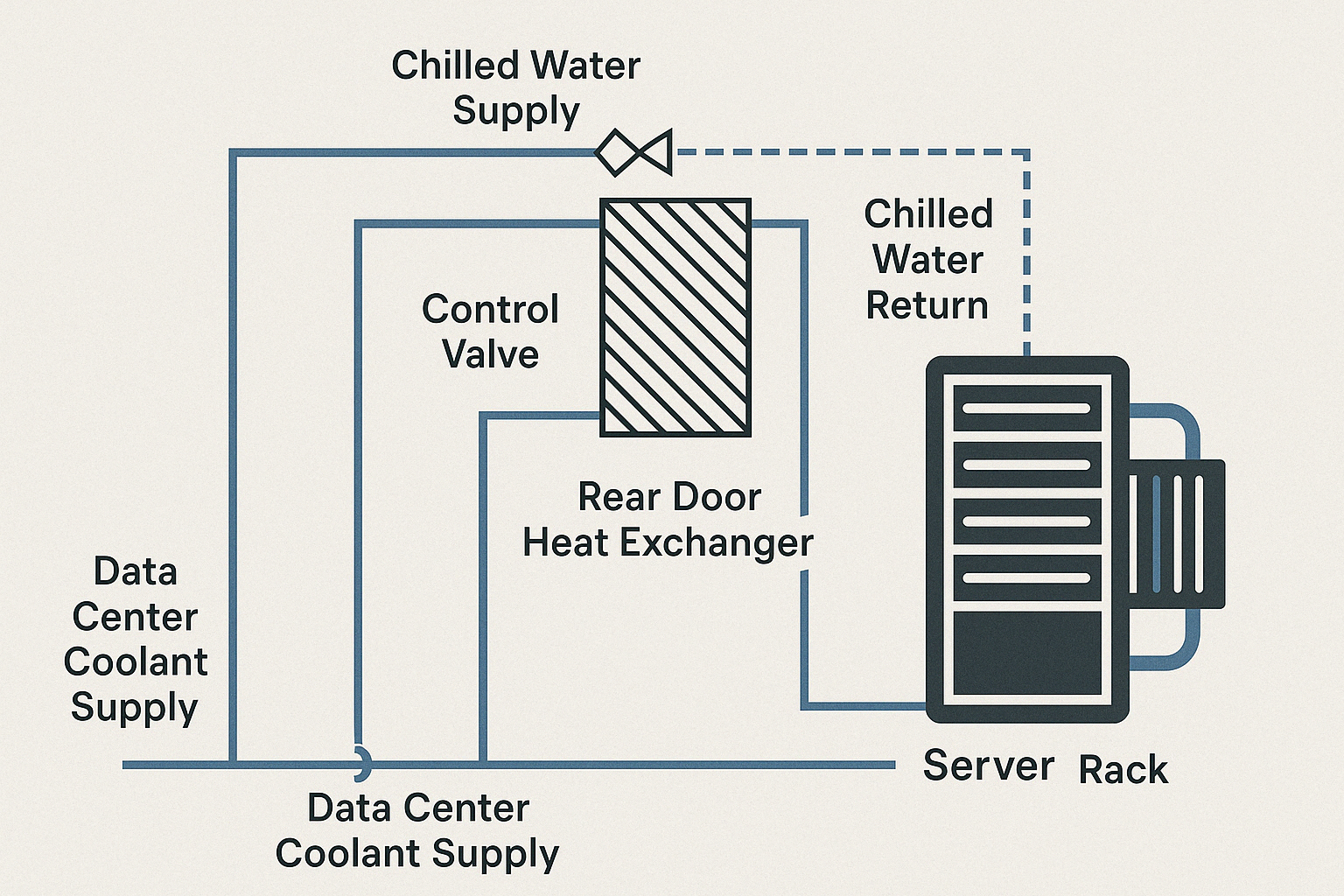

A Rear Door Heat Exchanger is a passive or active liquid-cooled panel mounted to the rear of a server rack. As hot exhaust air exits the servers, it is immediately passed through the RDHx. Here heat is transferred to a circulating liquid, typically chilled water or a refrigerant. This process drastically reduces the temperature of the exhaust air before it re-enters the data hall. This allows for significantly better containment and environmental control.

By absorbing thermal energy at the rack level, RDHx systems eliminate the need to cool the entire room volume. This is a fundamental inefficiency of traditional air-based systems. Moreover, they can often function without fans (passive RDHx) or with minimal airflow assistance (active RDHx), resulting in further energy savings.

Why Traditional Cooling Falls Short

In high-density environments — racks drawing 20 kW or more — the volumetric airflow required to maintain optimal operating temperatures becomes impractical for conventional systems. Hot aisle/cold aisle layouts with perforated tiles struggle to deliver sufficient cooling where it’s needed most: directly behind the compute nodes. In contrast, RDHx systems operate precisely where thermal transfer is most efficient—at the server exhaust point.

Studies such as those conducted by the Lawrence Berkley Laboratory, have shown RDHx cooling in high density deployments can reduce total data center cooling energy consumption by as much as 50%, with reductions of up to 80% in rack-level cooling loads. These figures are not just theoretical; they’re borne out in deployments by hyperscalers and enterprise clients alike.

Engineering Considerations and Coolant Infrastructure

The effectiveness of RDHx systems depends on several engineering factors:

Coolant Type and Temperature: While traditional chilled water systems operate at 7–15°C, some modern RDHx units can function with warm water (up to 40°C), enabling free cooling for much of the year. Systems like the IBM CoolBlue RDHx pioneered this concept, significantly reducing the mechanical cooling load.

Flow Rates and Thermal Transfer Surface: High-density racks may require water flow rates in excess of 15 GPM per rack. Heat exchanger design—including fin density and surface area—affects the heat transfer coefficient, which must be optimized for peak loads.

Piping and Connectivity: RDHx deployment involves integrating a closed-loop cooling circuit, either directly from a central chiller or via in-row CDU (Coolant Distribution Units). In facilities where flexibility is key, quick-disconnect fittings and overhead routing are recommended to minimize disruption during maintenance or reconfiguration.

Limitations and Mitigation Strategies

While RDHx systems offer remarkable benefits, they are not without challenges. The presence of liquid within or near IT racks introduces potential risk. A standard RDHx unit can contain several liters of water, and a leak—however rare—could be catastrophic in the absence of water leak detection systems. Integrating environmental sensors and automated alerts, such as those provided by AKCP, can mitigate this risk significantly.

Colocation environments, where tenants may frequently rearrange or scale their hardware, may find RDHx less flexible than air-based systems. However, innovations in modular CDU systems and flexible piping kits are helping to address these deployment challenges.

Maintenance is another consideration. While passive RDHx systems are relatively low-maintenance, active units with fans and pumps introduce mechanical components that require regular servicing. Properly scheduled preventative maintenance is essential to maintain cooling reliability.

The Road Ahead: Smarter and Greener Cooling

The next evolution of RDHx technology will likely involve deeper integration with DCIM platforms and AI-driven thermal mapping systems. Real-time feedback loops between thermal sensors and cooling systems can dynamically adjust flow rates and fan speeds, optimizing energy consumption without sacrificing performance.

Additionally, regulatory pressure and ESG mandates are pushing data centers toward lower carbon footprints. RDHx is well-suited for integration into liquid cooling ecosystems, including rear-door immersion hybrids and direct-to-chip cold plate systems, enabling participation in heat reuse programs and low-grade waste heat recovery.

Conclusion

Rear Door Heat Exchangers represent a transformative leap in data center cooling, addressing the bottlenecks of air-based systems in the face of escalating rack power densities. By managing heat at the point of generation, they enable tighter thermal control, greater rack utilization, and substantial energy savings. For operators of high-density or HPC facilities, RDHx is not just a cooling solution—it’s a strategic enabler of performance, scalability, and sustainability.