Understanding Dry Contacts: A Comprehensive Guide for Monitoring Systems

In the world of industrial monitoring, dry contacts play a crucial role in system integration. Understanding dry contacts can help you select the right type of dry contact for your application. In this blog post, we’ll dive into what dry contacts are, explore the different types available, explain how isolation technology works, and provide practical tips on selecting the right type for your needs.

What Are Dry Contacts?

Dry contacts, also known as volt-free or potential-free contacts, are essentially switches or relays that do not supply any voltage or current from their own source. They act like a simple on/off mechanism, opening or closing a circuit to signal status changes without introducing power into the monitored system. This isolation makes them ideal for interfacing with external devices, such as alarms, UPS systems, or HVAC controls, where you want to avoid electrical interference or hazards.

Unlike “wet contacts,” which have voltage applied directly (making them “wetted” by power), dry contacts remain neutral until connected to an external circuit. In monitoring systems, dry contacts are commonly used to detect events like door openings, fire alarms, or equipment failures. For instance, a dry contact might close when a smoke detector activates, triggering an alert in your monitoring software without risking voltage mismatches or ground loops.

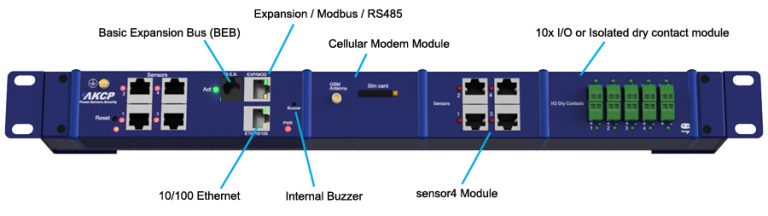

Dry contacts are versatile and allow the integration of third party systems to monitoring platforms such as the AKCP sensorProbe+ network enabled monitoring devices.

Types of Dry Contact Modules Available on AKCP Devices

AKCP, a leader in sensor-based monitoring solutions, offers a range of dry contact modules for their sensorProbeX+ base units. These modules expand the capabilities, supporting up to 30 dry contact ports on a single 1U rack mounted device. Additional modules are added through expansion units. The modules allow you to customize your setup based on the number and type of contacts you need to monitor.

Here’s a breakdown of the main types:

Isolated Contacts (D1i/D2i):

These are designed for safe, general-purpose measurements with systems that have volt-free interfaces. They include built-in isolation to protect against electrical noise and ensure safety. Ideal for standard monitoring where isolation is a priority, such as connecting to sensitive equipment. The “i” denotes isolation, typically handling up to 5VDC. These are the recommended type of dry contacts for use in most situations where input only is needed.

I/O Contacts (D1/D2):

These modules allow you to both output dry contacts (to control external devices) and monitor volt-free inputs. However, they lack additional circuit isolation, making them suitable for simpler setups where isolation isn’t critical. Use them for basic input/output tasks, like actuating relays or reading binary states.

20VDC Contacts (D1iV/D2iV):

Specifically for monitoring interfaces from other systems that output signals in the 5-20 VDC range. These are isolated versions, providing protection while handling low-voltage DC signals. They’re perfect for integrating with devices like power relays or control panels that emit DC voltage status signals.

20VAC Contacts (D1ACV/D2ACV):

Tailored for systems outputting 5-20 VAC signals, these modules monitor AC voltage inputs from external interfaces. Like the DCV variants, they include isolation for safety. They’re commonly used in AC-powered environments, such as detecting status from HVAC systems or older industrial controls.

These modules come in 10 or 20 port versions, (e.g., D1 for 10 ports, D2 for 20). This modularity makes AKCP sensorProbeX+ devices scalable for data centers or industrial applications.

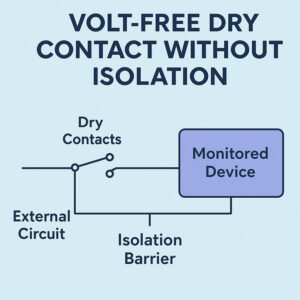

How Isolation Technology Works in Dry Contacts

Isolation technology in dry contact modules work by electrically separating the input (monitored side) from the output (monitoring device side), preventing direct current flow between them. This is crucial for avoiding ground loops, voltage spikes, or interference that could damage equipment or cause false readings.

The most common method is optical isolation (opto-isolation), which uses an optocoupler, a component consisting of an LED and a phototransistor sealed in a light-proof package. The process works as follows

- Signal Detection: When the dry contact closes (or opens), it triggers a small current to light up the LED on the input side.

- Optical Transmission: The light from the LED activates the phototransistor on the output side, which then switches the circuit without any physical electrical connection.

- Isolation Barrier: This optical link provides isolation, ensuring that high-voltage transients on one side don’t affect the other.

Other isolation methods include magnetic (transformers) or capacitive coupling, but opto-isolation is prevalent in dry contacts due to its reliability and low cost. In AKCP modules like D1i or D1iV, this technology enhances safety by isolating the inputs, making them suitable for harsh environments where electrical noise is common. Overall, isolation not only protects your AKCP device but also extends the lifespan of connected systems by minimizing wear from electrical stress.

How to Select the Correct Dry Contact Type for Your AKCP Device

Choosing the right dry contact module depends on your application’s requirements, including the type of interface. Here’s a step-by-step guide:

- Assess the Interface Type:

Determine if the system you’re monitoring is volt-free (no voltage output) or if it provides a voltage signal. For volt-free setups, start with D1i/D2i for isolated safety or D1/D2 for basic I/O without isolation.

- Check Voltage Range:

If the external system outputs voltage:

– Use D1iV/D2iV for DC signals between 5-20DCV.

– Opt for D1ACV/D2ACV for ACV signals in the same range.

This ensures compatibility and prevents damage from mismatched voltages. - Prioritize Isolation:

If your environment involves potential electrical interference, high voltages nearby, or sensitive equipment, always choose isolated modules (those with “i”). - Test and Configure:

Once installed, configure alerts via AKCP’s software and test with your specific devices. Define thresholds based on NO/NC states.

By matching the module to your system’s output, you’ll ensure reliable monitoring and avoid common issues like false alarms or equipment failure.

Conclusion

Dry contacts offer a simple yet powerful way to integrate and automate third party equipment with AKCP’s monitoring platform. Whether you’re dealing with volt-free alarms or voltage-output interfaces, understanding the different types of contacts and isolation techniques empowers you to make informed choices.

If you’re setting up an AKCP device or have questions about implementation, feel free to reach out to AKCP on sa***@**cp.com