Hot Aisle vs. Cold Aisle Containment: Optimizing Data Center Cooling and Integrating AKCP Monitoring Solutions

In the ever-evolving world of data centers, efficient cooling is paramount to ensuring reliability, reducing energy costs, and extending equipment lifespan. As server densities increase and power consumption rises, traditional cooling methods often fall short, leading to hotspots, inefficiencies, and higher operational expenses. Aisle containment strategies, specifically hot aisle containment (HAC) and cold aisle containment (CAC), have become essential for separating hot and cold airflows, preventing mixing, and optimizing airflow management. These approaches not only enhance cooling efficiency but also support sustainability goals by minimizing energy waste. This article explores the differences between HAC and CAC, their respective advantages and disadvantages, and how advanced monitoring solutions from AKCP can be integrated to maximize their effectiveness.

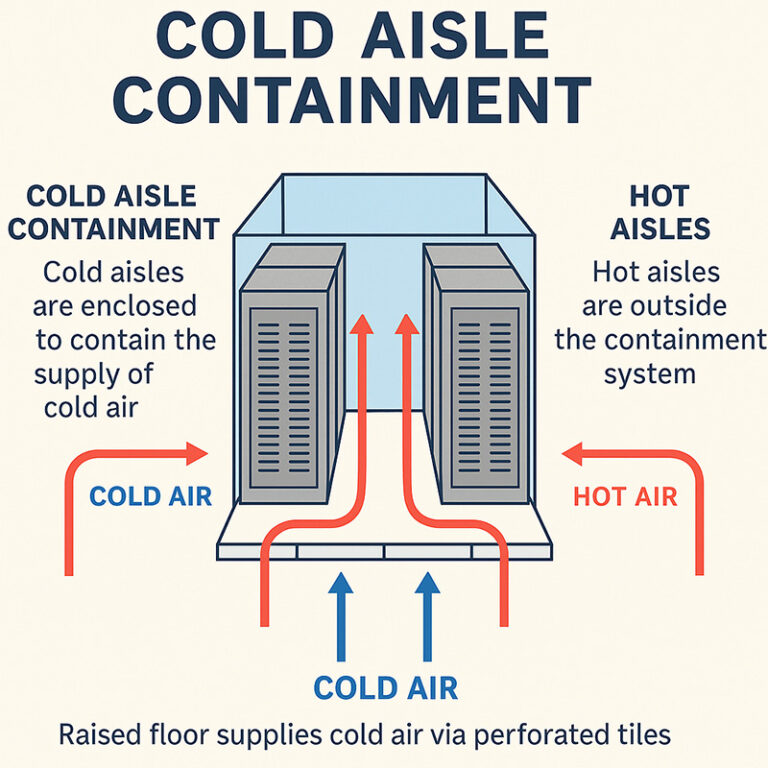

Understanding Cold Aisle Containment

Cold aisle containment focuses on enclosing the cold aisles where cool air is supplied to the front of server racks, to prevent it from mixing with hot exhaust air. Typically, this involves installing doors at the ends of the aisles and a roof or panels above them, creating a sealed environment for the incoming cool air from computer room air conditioning (CRAC) units or perforated floor tiles. The hot air expelled from the rear of the servers is then allowed to circulate freely in the open data center space before being drawn back to the cooling units.

Advantages of Cold Aisle Containment

- Ease of Implementation and Cost-Effectiveness: CAC is generally simpler and less expensive to install, as it doesn’t require extensive ductwork or drop ceilings. It’s ideal for retrofitting existing facilities with minimal disruption.

- Flexibility in Layout: It works well in environments with overhead obstructions and doesn’t always need a raised floor, making it adaptable to various data center designs.

- Improved Ride-Through During Outages: By containing cool air, CAC provides a larger “cold sink” area, offering better thermal buffering if cooling fails temporarily.

Disadvantages of Cold Aisle Containment

- Hotter Overall Room Temperature: The data center space outside the contained aisles becomes the de facto hot aisle, potentially leading to uncomfortable working conditions for technicians and risks to non-contained equipment.

- Fire Suppression Challenges: Under codes like NFPA, CAC can create a “separate volume,” necessitating additional smoke detection or suppression systems, which adds complexity and cost.

- Potential Efficiency Losses: Leakage of conditioned air into hot paths can reduce the temperature differential (delta T) across cooling units, lowering overall system efficiency.

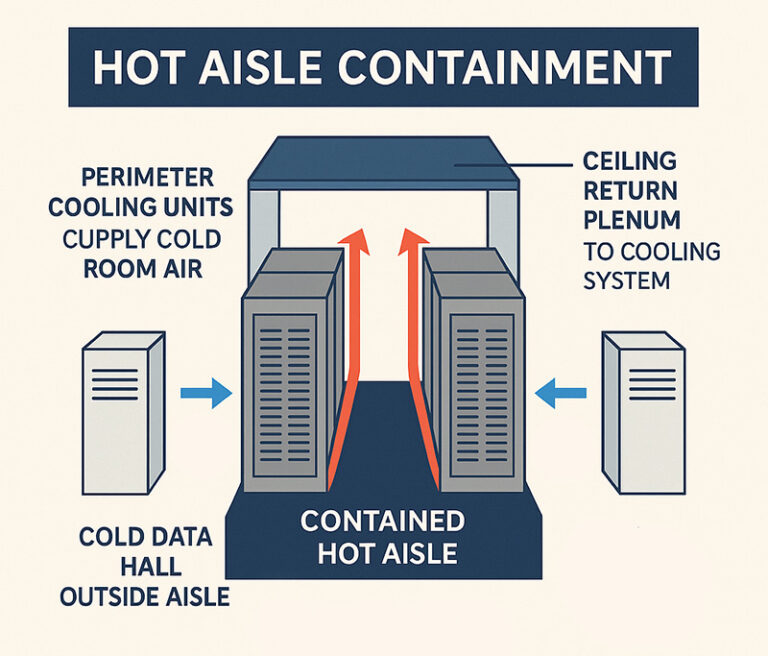

Understanding Hot Aisle Containment

In contrast, hot aisle containment encloses the hot aisles, where servers exhaust warm air, to isolate and direct it back to the cooling units via ducts, plenums, or chimneys. Cool air is supplied to the open data center space, flooding the room and entering the front of the racks unimpeded. This setup often uses drop ceilings or dedicated return paths to channel hot air efficiently.

Advantages of Hot Aisle Containment

- Cooler Working Environment: The main data center area remains cool, improving comfort for maintenance staff and allowing non-contained equipment to operate in lower temperatures.

- Higher Efficiency and Density Support: HAC can handle higher server densities by maintaining consistent intake temperatures and reducing bypass airflow, often leading to energy savings of 10-35% through better air separation.

- Better Compatibility with Fire Systems: It typically doesn’t create isolated volumes, simplifying compliance with fire codes and integrating seamlessly with existing suppression setups.

Disadvantages of Hot Aisle Containment

- Higher Installation Costs and Complexity: Requiring ductwork or plenums increases upfront expenses and may not suit all layouts, especially those without raised floors.

- Maintenance Challenges in Hot Zones: Technicians may need to work in hotter enclosed areas, though front-serviceable servers can mitigate this.

- Dependency on Infrastructure: It’s less forgiving in slab-based data centers without proper air return paths.

Hot vs. Cold Aisle Containment: Which is Better?

The choice between HAC and CAC depends on site-specific factors like existing infrastructure, budget, equipment density, and operational needs. Studies, such as one by Intel and T-Systems, show no significant efficiency differences between the two when properly implemented, with both capable of reducing cooling energy by preventing air mixing. However, HAC is often recommended for its thermal ride-through advantages, better handling of leaks, and overall flexibility in modern high-density setups. CAC, on the other hand, shines in cost-sensitive retrofits where simplicity is key.

| Aspect | Cold Aisle Containment | Hot Aisle Containment |

|---|---|---|

| Cost | Lower upfront and operational costs | Higher due to ducting/plenums |

| Efficiency | Good, but potential delta T reduction | Often superior with better air separation |

| Comfort | Hotter room environment | Cooler room, hotter enclosed aisles |

| Implementation | Easier, less infrastructure needed | More complex, requires return paths |

| Best For | Retrofits, low-density setups | High-density, new builds with fire compliance |

Ultimately, both strategies outperform open layouts, but evaluating bypass airflow and pressure management is crucial for success.

The Critical Role of Monitoring in Aisle Containment

No containment strategy is complete without robust monitoring to ensure optimal performance. Real-time data on temperature, humidity, airflow, and pressure differentials helps detect leaks, imbalances, or failures early, preventing downtime and inefficiency. Monitoring also enables predictive maintenance, such as filter replacements, and supports dynamic adjustments to cooling systems.

Incorporating AKCP Monitoring Solutions

AKCP, a leader in environmental monitoring with over 30 years of experience, offers tailored solutions for data center aisle containment. Their wired and wireless sensors integrate seamlessly into HAC or CAC setups, providing granular insights to maintain ideal conditions.

- SensorProbe+ Series: These compact, network-enabled devices support multiple sensors for temperature, humidity, and differential pressure monitoring. In CAC, they can track air pressure to ensure positive pressure in cold aisles, preventing hot air infiltration. For HAC, sensors placed in hot aisles monitor exhaust temperatures to optimize return air paths.

- Wireless Tunnel Sensors: Ideal for large-scale deployments, these battery-powered units offer flexibility in contained environments, monitoring rack-level metrics without cabling hassles. They help create a “Digital Twin” of the data center for scenario planning and optimization.

- Power and Environmental Monitoring: AKCP’s solutions extend to power draw at rack levels, integrating with DCIM software for comprehensive oversight. In test setups like AKCP’s own hot aisle containment pod, these tools demonstrate real-world efficacy, including fan walls and heat exchangers.

By deploying AKCP sensors at strategic points such as aisle ends, rack inlets/outlets, and CRAC returns, operators can receive alerts via email/SMS, visualize data through dashboards, and automate responses to maintain containment integrity. This not only enhances the benefits of HAC or CAC but also reduces energy costs by up to 30% through precise control.

Conclusion

Hot and cold aisle containment represent proven strategies for data center cooling, with HAC often edging out for efficiency in demanding environments and CAC for affordability in simpler ones. However, their true potential is unlocked through vigilant monitoring. AKCP’s innovative solutions provide the tools needed to monitor, analyze, and optimize these systems, ensuring data centers run cooler, greener, and more reliably. As data demands grow, investing in containment paired with advanced monitoring like AKCP’s will be key to future-proofing operations.