Detect Hotspots and Coldspots in your Data Center

Thermal map sensors help identify and eliminate hotspots in your cabinets by identifying areas where temperature differential between front and rear are too high.

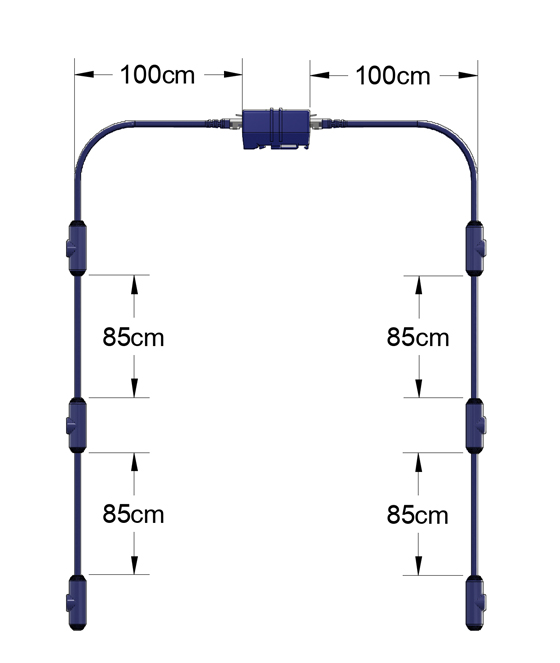

The Rack Thermal map sensor consist of a string of 3x temperature sensors and optional 1x humidity sensor. They are placed at the top, middle and bottom of the rack. Two strings can be combined on a single sensor port front and rear of the cabinet. Thermal map sensors monitor the air intake and exhaust temperatures of your cabinet, as well as the ∆T of the rack. Use thermal map sensors to identify cabinet hot spots that can endanger your uptime.

Thermal map sensors identify coldspots in your data center, eliminating cold spots frees sttranded capacity and saves energy.

Are there areas of your data center that are over cooled? Over cooling wastes energy. Identifying and eliminating cold spots can increase data center energy efficiency and lower operational costs. Furthermore, you can release stranded capacity, increasing server loads in cold spots allows increased compute power without any increase in cooling capacity.

Thermal map sensors connect to AKCP sensorProbe+ base units. Extendable up to a maximum of 15 meters cable length, you can monitor multiple cabinets from a single IP address. Up to 16 thermal maps can be connected to a single SPX+, or deploy the SP1+ on each rack.

The sensor splitter box allows 2 strings to be connected to a single sensor port, and combined with the contactless current meter to give thermal mapping and power monitoring for each rack. This is required for AKCP sensorCFD™ calculations.

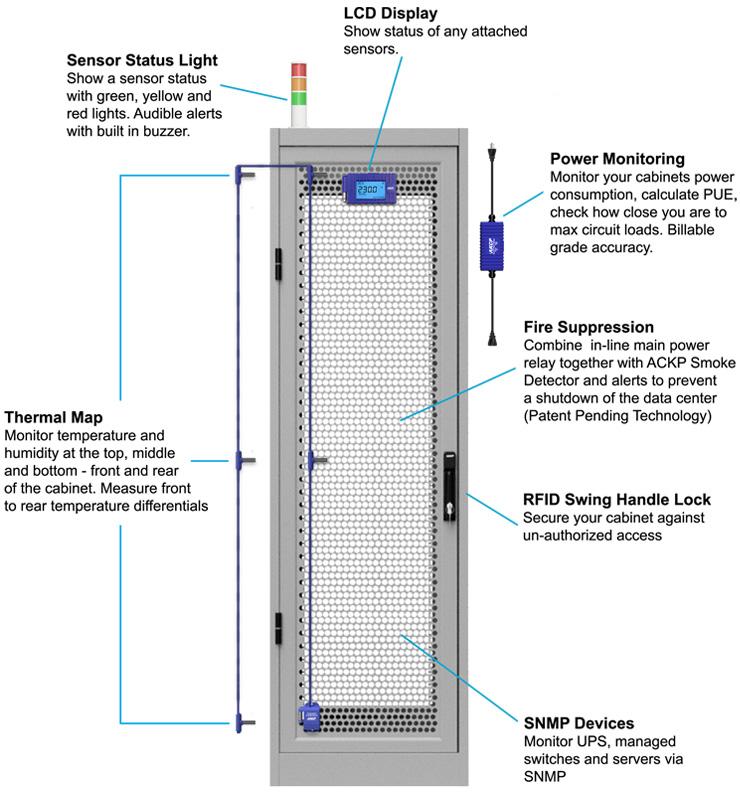

AKCP Data Center Monitoring

Build a complete rack monitoring system connecting AKCP sensors to your SP1+. Fully SNMP compliant, monitor from your existing NMS or using our DCIM AKCPro Server.

| Dual Temperature | |

| Measurement Range | -40°C to +75°C -40°F to +167°F |

| Measurement Resolution | 0.1°C increments 0.2°F increments |

| Measurement Accuracy | Maximum ±0.3 at -40ºC, minimum ±0.3 at +25ºC to +75ºC Maximum ±0.6 at -40ºF, minimum ±0.6 at +77ºF and to +167ºF |

| Dual Humidity | |

| Measurement range | -0 to 100% Relative humidity |

| Measurement Resolution | 1%RH increments, 0.01%RH sensor reading |

| Measurement Accuracy | At 25°C Min : ±2%RH Max : ±5% RH |

| Interface | |

| Communication Cable | RJ45 jack to sensor using UTP CAT5e/6 |

| Power Source | Powered by the sensorProbe+ family units. No additional power needed. |

| Power Consumption | Typical 75 mWatt, 15 mA |

| Maximum Cable Length | Sensor canbe extended from the RJ-45 Intelligent Sensor ports on the Base units up to 60 feet, or 18 meters using standard CAT5-6 LAN cable |

| sensorProbe+ units auto detects the presence of the Cabinet Thermal Map Sensor | |

| Dimension | 75 x 55 x 27 mm |

| Mounting | VHB Tape, Magnetic (optional) |

| Components | Manufactured using highly integrated, low power surface mount technology to ensure long term realibility. |

| Operation Environment | Temperature: Min. -35°C – Max. 80°C Humidity: Min.20% – Max. 80% (Non-Condensing) |

| Sensor count | THMS-V2: 4 CTHMS-V2: 11 |