Data Center Monitoring and Optimization

Manage thermal risks in the data center. Ensure 100% ASHRAE compliance at rack level, minimize downtime and increase equipment service life.

Data Center Monitoring Solutions

Lack of Data Center Monitoring and Optimization leads to one of the most common cause of unplanned data center downtime. Failure to manage the thermal risks posed by overheating servers. Almost 1/3 of data center downtime are traced to overheating. Due to this, many data centers mitigate the risks by overcooling, which results in wasted energy, increased carbon emissions and OpEx. AKCP’s data center monitoring and optimization solutions with Thermal Map Sensors and AKCPro Server Heatmaps you can have the best of both worlds, identify hot spots and cold spots for optimal efficiency and lower PUE.

Monitoring temperature, power, and security in a data center is essential not just for safety and compliance, but also for improving operational efficiency. When implemented correctly, these systems help reduce energy consumption, prevent downtime, and ensure that both equipment and data remain secure. Here’s how each aspect contributes to a more efficient data center environment.

Temperature Monitoring

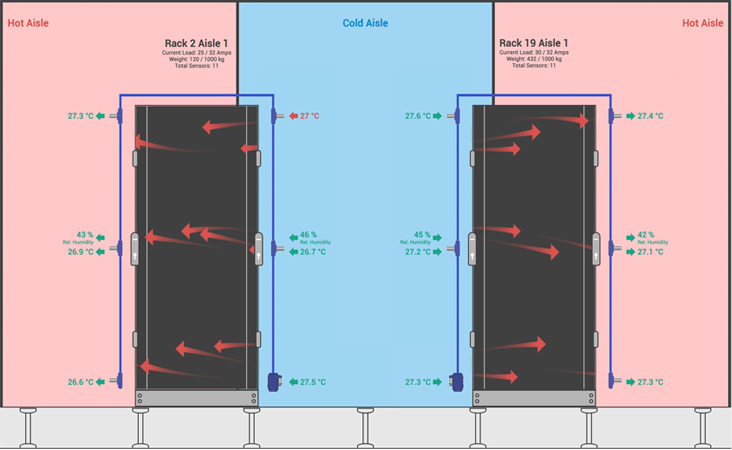

Temperature is a critical parameter in data center operations. Overheating is one of the primary causes of hardware failure, while excessive cooling wastes energy. Effective temperature monitoring allows operators to maintain conditions within manufacturer-recommended ranges, particularly those outlined by ASHRAE. By deploying intelligent sensors—such as AKCP’s cabinet thermal map sensors—data center managers can monitor inlet and outlet temperatures on a per-rack basis. This granular visibility enables targeted cooling strategies such as hot aisle/cold aisle containment or variable-speed fan control, which can significantly reduce power consumption.

Temperature data can also be used to identify inefficient airflow, such as bypass or recirculation zones. These anomalies are typically invisible without detailed monitoring but contribute to overcooling in some areas and overheating in others. By analyzing thermal data across different zones in the data center, operators can optimize airflow and cooling distribution, leading to a direct improvement in energy efficiency.

Power Monitoring

Power usage effectiveness (PUE) remains the industry-standard metric for evaluating data center efficiency. To calculate PUE and identify inefficiencies, real-time power monitoring is essential. AKCP’s solutions allow monitoring at various levels—from main feeds and branch circuits down to individual racks or equipment. By collecting data on power draw, current, voltage, and power factor, data center managers gain a complete view of electrical consumption patterns.

Through this insight, underutilized or energy-hungry systems can be identified. Equipment running idle or consuming excessive standby power can be scheduled for shutdown or upgraded. Furthermore, power monitoring helps in load balancing and capacity planning—ensuring power circuits are not overloaded and can accommodate expansion without risk.

Monitoring also provides early warning of anomalies such as voltage sags, spikes, or power imbalances, which could damage sensitive IT infrastructure or trigger costly downtime. With real-time alerts and historical data logging, facilities can transition from reactive to proactive maintenance, extending the life of their infrastructure and avoiding service interruptions.

Security Monitoring

Physical security is often overlooked in efficiency discussions, but it plays a vital role. Unauthorized access can lead to equipment tampering, data breaches, or operational disruptions. AKCP’s integrated access control systems with RFID authentication ensure that only authorized personnel can enter critical areas or open individual server cabinets.

Monitoring door contact sensors, motion detectors, and video surveillance feeds also improves accountability and auditability. In high-security environments, linking physical access logs with environmental changes (e.g., temperature spikes after a door is opened) helps diagnose problems faster and prevent potential sabotage or user error from causing broader issues.

From a compliance perspective, maintaining logs of access events and environmental data supports ISO 27001 and other regulatory standards, which can streamline audits and reduce operational risk.

Real-time Heatmaps

2D heatmaps constantly update with sensor data at rack level. Each rack has 6 temperature sensors (3 at front and rear, top middle and bottom). Quickly identify hotspots, high rack inlet temperatures and incorrect ∆T’s.

Monitoring Hotspots

Identify hotspots with AKCPro Server Heatmaps. Raise visual and audible alarms, SNMP traps, E-mail and SMS. With full SNMP V1/2/3 compatibility it easily integrates with existing NMS, BMS and DCIM software.

24/7/365 Thermal Optimization

Be pro-active with thermal management and optimization of your data center. Sense disaster and be in control before critical infrastructure fails. As data center loads change identify areas of cost saving. Utilize sensors as an analysis tool not only for alerts.

Comply with ASHRAE and Uptime Institute

with sensors placed at each rack you can ensure 100% compliance with ASHRAE and Uptime Institutes recommended temperatures and sensor placement. Thermal shutdown accounts for 1/3 of data center outages. Reduce the risk of thermal shutdowns with sensors.

Software Solutions

Central management and monitoring software for all AKCP devices. DCIM with focus on temperature and airflow analysis. 2D and 3D vizualitation of the data center with heatmaps, sensor constrained CFD and differential air pressures.

Central management and monitoring software for all AKCP devices. DCIM with focus on temperature and airflow analysis. 2D and 3D vizualitation of the data center with heatmaps, sensor constrained CFD and differential air pressures.

Hardware Solutions

Combine temperature and humidity mapping, non-invasive current metering and pressure sensors. 6x temperature, 1x humidity, 1x current, 2x pressure, 3x ∆T and 1x ∆P for a total of 14 sensors per rack. Analyze data with AKCPro Server.

Combine temperature and humidity mapping, non-invasive current metering and pressure sensors. 6x temperature, 1x humidity, 1x current, 2x pressure, 3x ∆T and 1x ∆P for a total of 14 sensors per rack. Analyze data with AKCPro Server.