Rack Cooling Solution for High-Density Data Centers

What is a High-Density Server Rack?

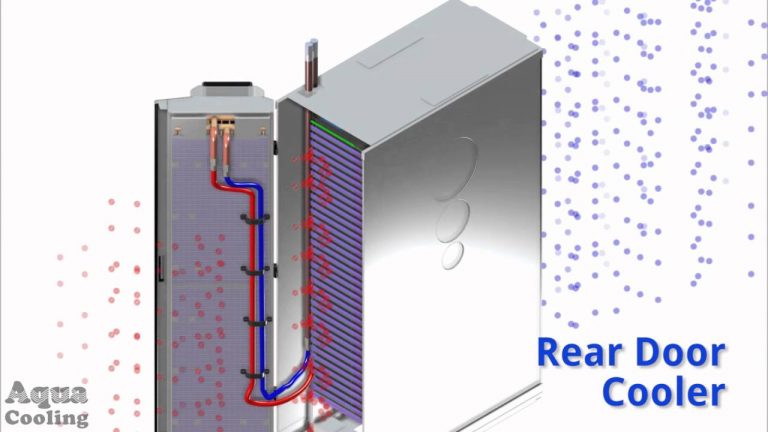

How RDHX Rack Cooling Works?

Energy Efficiency

Cooling Efficiency

Common Problems in Rear Door Exchange Heater

- Water Leakage – There is a risk of water leaks. For instance, IMB RDHX holds six gallons of water supporting a flow rate of up to 10 gallons in a minute. In this case water leak detection sensors would be essential.

- Air Leakage – For data centers with UFAD, air needs to be distributed properly. This air may also leak as the cabinet doors are not fit tightly. This will be followed by an increase in inlet temperature. This should be considered as leakage mitigation is more effective than reducing temperature. Cabinet analysis sensors with differential air pressure can detect these problems.

Airflow Management Rear Door Exchange Heater

- Before Implementation – The server rack design needs to be done accordingly before running a data center with RDHX. With this, the hot and cold layout can possibly be eliminated. Instead, racks can be arranged in a way where air from a rack outlet supplies air to an adjoining rack’s inlet.

- During Implementation – Consistent monitoring of the temperature and airflow is essential while operating. It allows the administrators to keep track of the current condition of the facility. It also helps in visualizing potential problems and set necessary adjustments.

- After Implementation – Measuring energy consumption after designing the data center into RDHX test the energy efficiency. This can be through the measurement of power usage effectiveness or PUE. With this, you can see how well you did and look for opportunities to improve it.

See more about PUE here. AKCP FREE PUE CALCULATOR.

How Do Sensors Work in RDHX?

Power Monitoring Sensor

Combining this durable Power Monitor Sensor with the sensorProbe+ and securityProbe creates an IP-enabled power monitoring capable of monitoring/measuring:

- Phase Line Voltages

- Current

- Power Factor

- Active Energy

- Active Power

Airflow and Thermal Mapping for IT Cabinets

Airflow and Thermal Mapping for IT Cabinets

The Cabinet Analysis Sensor (CAS) features a cabinet thermal map for detecting hot spots and a differential pressure sensor for analysis of airflow.

Differential Temperature (△T)

Cabinet thermal maps consist of 2 strings of 3x Temp and 1x Hum sensor. Monitor the temperature at the front and rear of the cabinet, top, middle, and bottom. The △T value, front to rear temperature differential is calculated and displayed with animated arrows in AKCPro Server cabinet rack map views.

Conclusion

Reference Links:

https://www.datacenterknowledge.com/archives/2017/05/22/rdhx-systems-help-with-high-density-data-center-cooling

https://datacenters.lbl.gov/sites/all/files/rdhx-doe-femp.pdf

https://www.opencompute.org/documents/acs-door-hx-open-compute-requirements-for-open-rack-rev0-95-1-pdf

https://www.missioncriticalmagazine.com/ext/resources/whitepapers/shlomo-WP-RDHx-Cost-Effective-Alternative-to-CRAH-120811.pdf

https://www.vertiv.com/49cfee/globalassets/shared/liebert-dcd-passive-and-active-brochure_0.pdf