The rising energy consumption of data centers forced the industry to get underway for energy efficiency. Data centers located in the United States alone consumed more than 90 billion kilowatt-hours of electricity. That comes as no surprise considering the number of servers working non-stop. Several solutions are introduced, including the cold aisle containment- one of the most promising. According to a study, it can have an estimated 20% of savings in chiller operating cost.

However, these new solutions also present new challenges. Optimizing airflow can be difficult without a clear picture of air movement. Knowing that data centers deliver critical missions, it is important to understand airflow patterns when implementing cold aisle containment.

What is Cold Aisle Containment?

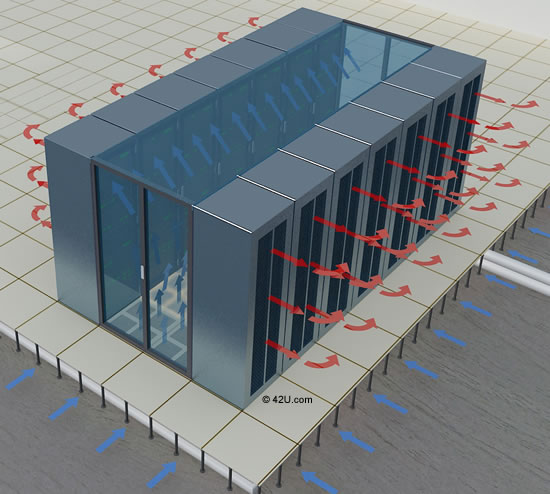

A cold aisle containment system (CAC) isolates that cold air through a physical barrier. This makes the rest of the room a large hot-air return plenum. Although the deployment of CRAG units works well, it may not be as effective on high-density data centers. It ensures that supply air from the cooling units is delivered directly to the server inlet through the perforated tiles. CAC solution prevents cold air from mixing with hot air, thus mitigating the risk of hotspots.

Generally, administrators think that equipment problems are caused by inadequate cooling. This is bridled by setting the air conditioning units at maximum. But this one is out of the way to energy efficiency. Retrofitting the data center into a cold aisle containment counters this inefficiency without compromising cooling.

Retrofitting Cold Aisle Containment

Cold aisle containment is easier to implement compared to hot aisle containment. This can be done quickly without having a shutdown. It is also cheaper as it works with or without conventionally raised floor cooling. Existing data centers can be retrofitted with this design without massive disruption of the facility.

Retrofitting the data center into cold aisle containment starts by arranging the racks. They should be on a hot and cold layout. The cooling unit is deployed on a raised floor outside the aisle. This can typically cool 10 to 15 kW of heat load for every rack. Curtains or doors enclose the end of the cold aisle, while ceiling panels are installed to seal the top. Furthermore, each slot of the racks must be occupied by a server. Otherwise, fillers or blanking panels should be used to cover the unused rack space.

Benefits of Cold Aisle Containment

With the fast pace evolvement of data centers, several solutions have “come and go.” Cold Aisle containment, however, remains on the line. This is due to the benefits it offers to the owners and administrators. According to Uptime Institute Survey, 800 out of 1,000 data centers indicate that cold aisle containment improved their operation. Aside from energy efficiency and optimized cooling, it also contributes the following:

-

Increasing the lifespan of the equipment

The environmental condition plays a critical role in equipment capability. High temperature can cause overheating, while low temperature makes the equipment a good area for molds to grow.

-

Redundancies in case of failure

Occasional failure is inevitable, making redundancy or battery back-up essential. Cold aisle containment makes the operating environment more predictable due to the separation of intake and exhaust air.

-

Environmental Friendly

CAC lets a data center operate in a greener way without increasing CapEx by reducing carbon emissions.

-

Proper Air Distribution

Air is distributed more efficiently to where it is necessary because of the barriers.

Differential Pressure: Challenge for Cold Aisle Containment

Before proceeding to cold aisle containment, understanding its consequences is a must. The practices mentioned above are the basics of containment. Total efficiency can only be achieved if they are done accordingly.

It is recently found out that issues may happen in failure to keep track of airflow. Servers may vary on speed fans. The airflow of the cooling units must be identical to the total airflow inside the containment. This imbalance is called differential pressure. Administrators can have thorough analysis by using Computational Fluid Dynamics (CFD)– a program used for data center containment systems.

Photo Credit: heinz-mech.com

-

Positive Pressure

Positive pressure occurs if the air provided by the cooling system is more than what the equipment requires (P1>>P2). Excess air will leak into the hot aisle due to the flexible nature of the containment system. In most cases, a server with a positive differential pressure of 0.05 in H20 will leak about 9.5 cfm per U during operation. In this situation, there will be inadequate air outside the containment. Moreover, server fans may overblow, significantly reducing their lifespan.

-

Negative Pressure

When the supply air is inadequate based on the need of server inlet, there will be a negative pressure (P1<<P2). The containment system will draw hot air to comply with the volume required. This results in hot and cold air mixing. In this situation, servers won’t get enough air to avert the heat that they produce. This contributes as the main culprit of data center downtime.

The Importance of Understanding Pressure in Cold Aisle Containment

Pressure is a valuable parameter in gaining insights into the effectiveness of the cooling system. By understanding the differential pressure, airflow can be better contained and directed into the cold aisle. Data Center Dynamics (DCD) validated the essence of airflow and pressure in their study. It so stated that:

Changes in differential pressure indicate improvement in airflow management. The cooling and airflow efficiency effort of the administrators can be easily evaluated. It can also manifest unobtrusive circumstances that might cause poor airflows, such as air leaks and damaged fans. Knowing this, changes to the configuration can be made to optimize the flow. For instance, allocating cooling resources to specific areas if necessary. This ensures a more reliable and efficient data center operating environment.

Pressure Control

An ideal data center is designed with zero differential pressure operation. However, a lot of data centers still find it too challenging. To control it, having a consistent monitoring system in the facility is essential.

There are two solutions recommended:

-

Temperature Control

Temperature sensors are usually placed on the containment walls to measure the air flowing through. This creates a correlation between the temperature and the air pressure or flow changes. Low temperature indicates excess cold air or the presence of positive pressure in the containment. Whereas an increase in temperature means that hot air started to leaked resulting in negative pressure.

-

Pressure Control

Pressure helps drive the airflow. Cooling units are tightly connected with the equipment. So more than the proper temperature, it is also important to have the cooling airflow at the correct pressure. A pressure difference of 20 Pa is maintained between the cold and the hot aisle. In installing pressure sensors, administrators need two points with different air pressure. In this case, this can be the contained and uncontained space. Other areas for monitoring differential pressure include air plenum and vents and server racks.

Both monitoring systems allow data centers to achieve the effectiveness of cold aisle containment. It can help assure that the investment in the solution will generate the return on the estimated period.

How Differential Air Pressure Sensor Helps in Cooling

Optimize the cooling and airflow system in Data Center. The sensors will help to understand the airflow patterns and monitor their efficiency throughout your Data Center.

You may for example place one part of the sensor inside the hot aisle, and another in your cold aisle. The pressure difference between the two would indicate if you have proper airflow from cold to hot. If there was a positive pressure differential in the hot aisle, it would indicate you have hot air leaking back into your cold aisle.

In another case, you can place the pressure tubes at the front and rear of the cabinet. There should always be positive pressure at the front of a server cabinet. Air travels from areas of high pressure to low pressure, and it is imperative for efficient cooling to check that there is higher pressure at the front of the cabinet and lower pressure at the rear. However, this doesn’t show the volume of the airflow, only the force at which the air is being pushed.

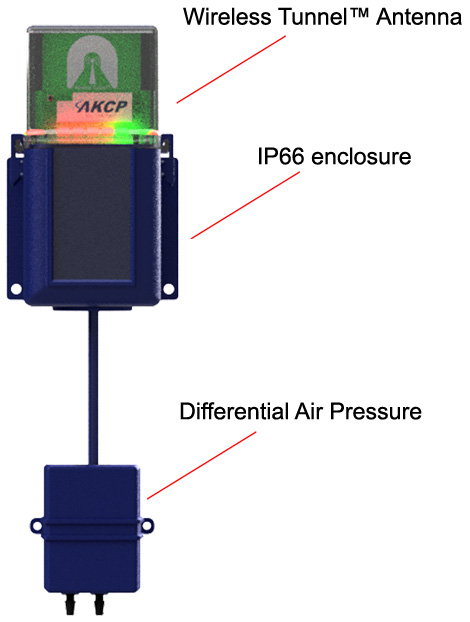

Wireless Air Pressure Differential

Wireless Air Pressure Differential Sensor

This sensor monitor cabinets for pressure differential to ensure adequate airflow. Air Pressure Differential Sensors can also be utilized in facilities where positive pressures are maintained inside rooms to keep them clean, or negative pressures to contain contaminants.

Sensor Details

- 4x AA Batteries

- External 5VDC or 12VDC power

- LED indicators for power, status, and RSSI

- Optional DIN rail or pipe mounting

Airflow Sensor

AKCP Airflow Sensors

The AKCP Pro airflow sensor is designed for systems that generate heat in the course of their operation and requires a steady flow of air to dissipate this heat generated. System reliability and safety could be jeopardized if this cooling airflow stops.

The Airflow sensor is placed in the path of the air stream, where the user can monitor the status of the flowing air. The airflow sensor is not a precision measuring instrument. This device is meant to measure the presence or the absence of airflow.

In addition to the sensor’s ON or OFF status, the airflow sensor’s condition can also be read via an SNMP get using its OID. SNMP traps are sent when critical. SNMP polling via getting available. Web browser interface available. When an alarm condition is activated the description and location of the fault can be sent via email, page.

Reference Links:

https://www.keyzone.com/what-we-do/cold-aisle-containment

https://www.42u.com/solutions/data-center-containment/cold-aisle-containment/

https://www.packetpower.com/blog/optimizing-data-center-cooling-using-differential-pressure-sensing

https://datacenterbrainstorm.com/the-importance-of-pressure-control-in-cold-aisle-containment-cac/

https://www.datacenterdynamics.com/en/news/server-leakage-and-cooling/