Understanding The Science Behind Containment

- Lowering the occurrence of hotspots.

- Take advantage of the cooling capacity of an air conditioning unit.

- Preventing the need for added cooling units.

- Reducing costs.

Identifying The Science Behind Containment Solutions

There are different containment approaches. These approaches are practically customized to fit a data center’s needs. Ultimately, the containment process endeavors to provide these benefits:

- Efficient energy output.

- Lowering of bypass airflow rate.

- Efficient cooling turnout.

- Enable added rack and server load without compromising cooling capacity.

- Extends IT equipment’s lifespan.

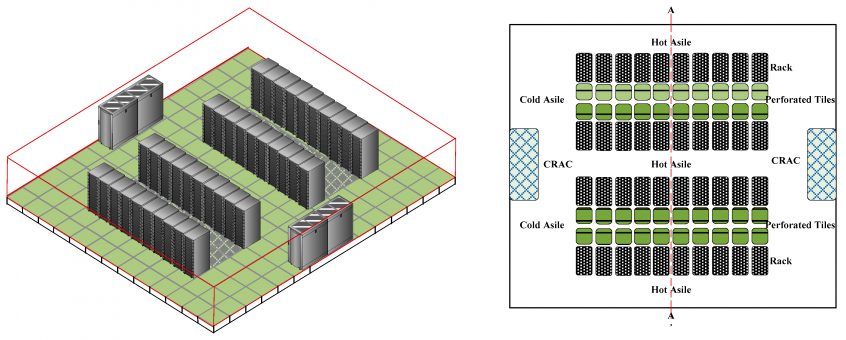

Hot Aisle Containment

- A 30% cooling efficiency increase

- Easy installation process compared to other grid systems

- No need for additional trades on site

- No mixing of hot and cold air as containment separates the airflow

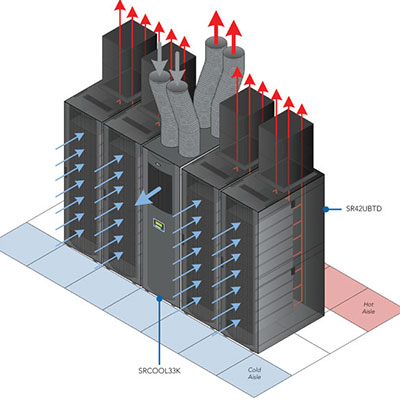

Cold Aisle Containment

The biggest consideration in a cold aisle containment system is the crucial role of airflow controls. Cold aisles work to facilitate a uniform level of cold air to flow into the IT equipment. To manage the constant level, airflow controls are needed to predict the supply of air for a particular aisle. A predicted airflow prevents hot spots. It also highlights optimal operating efficiency. Ultimately, cold aisles work best to provide intake air temperatures at a constant setpoint.

There are also different modes of configuration for a cold aisle. Again, this is dependent on the performance demands a data center works for. It comes in these basic forms:

- Single or Double Sliding Doors with a Hard Roof.

- Hard division along with Single or Double Sliding Doors.

- Soft divisions incorporated with Strip Doors.

- Single or Double Sliding Doors alongside Directional Airflow Panels.

Virtual Containment

- Containment roofs negate the flexibility of the infrastructure

- Requires bigger cost investment

- Critical risk in fire occurrences

- Require additional lighting systems

- Limits data center service distribution

Is Airflow Management Better Than Cooling Optimization?

- Containment systems are major heat repellants. When heat dissipates, the desired temperature is sustained. At best, it will fall within serviceable industry levels.

- Airflow controls in a cold aisle containment allow better maintenance of ideal temperature at 65°F to 80°F. Also, it lessens the energy expenditure and negates wastage and variable costs.

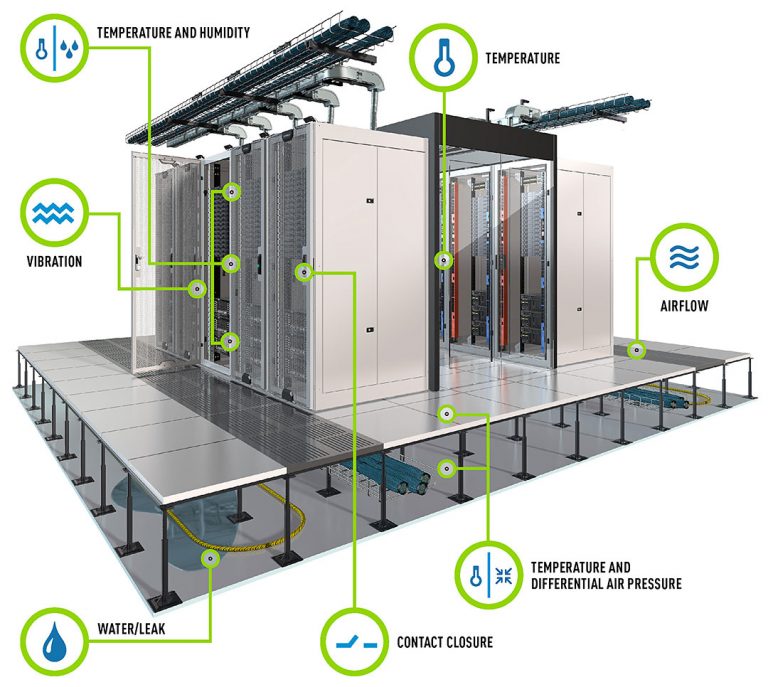

Sensors As Containment Optimizers

- In a cold aisle containment system, AKCP dual temperature and humidity sensors can check and maintain aisle temperature. The constant gauge can ensure that aisle is in standard condition and is not extracting too much energy because of cooling.

- For IT cabinets along the aisle, AKCP temperature sensors can be placed at the front and rear, top, middle, and bottom. It can predict temperature differential from the front to rear providing better data oversight when monitoring.

- To check airflow in cold and hot aisles, AKCP air pressure sensors check on pressure differences to prevent hot air from mixing in the cold aisle.

- Incorporating an intelligent monitoring system requires other sensors to check on water leaks and access controls. The rope water sensors by AKCP can be positioned under access floors, at different rack levels, and aisle access enabling better control.