Every data center has an invisible ceiling that limits the amount of IT equipment, servers, storage, and network devices that it can handle. This is known as the capacity of the data center. To make the most of data center floor space there has been a shift towards high-density computing. Data centers must guarantee that localized cooling capacity is enough to match non-uniformly distributed heat loads. Non-uniform because a data center is a “living breathing animal” some racks may be working at higher loads than others at different times of the day. The original Mechanical Electrical Plumbing (MEP) architecture and data center location choice have already substantially determined a data center’s power and cooling capability. The combination of power, cooling, and floor space creates an unseen barrier that leads to the concept of stranded capacity. Because of the system’s design or configuration, stranded capacity is the capacity that cannot be used by IT loads. It’s incredibly expensive for data centers to fail to meet the operating and capacity needs of their initial design, and getting your data center green is a challenge.

Stranded Cooling Capacity

Stranded cooling capacity is the most expensive type of stranded capacity since it refers to any part of the mechanical system that is working but not contributing to cooling IT equipment. Wasted cooling energy is one of the consequences of stranded capacity and consequently money. But just because you can’t see the issue doesn’t imply it doesn’t exist. With that in mind, here are the effects of stranded capacity a data center manager should be concerned about:

Effects of Stranded Cooling Capacity

Photo Credit: www.edpeurope.com

- There Is More Stranded Capacity In Most Data Centers Than You Might Think

The data clearly revealed that there was 3.9 times more cooling capacity than IT load at the last 45 sites analyzed by Upsite. This means a lot of fan horsepower is being used unnecessarily, and money is being spent on cooling equipment that is not needed.

- Low Cooling Unit Temperature Set Points Can Strand Capacity

Manufacturers rank their cooling units based on conventional return-air conditions, which are typically 75°F with a relative humidity of 45%. However, because most sites run their cooling units at lower setpoints than recommended, the rated capacity cannot be met. Because the cooling unit’s cooling capacity reduces at lower return-air temperatures, this results in a very costly situation of more cooling units working.

A typical 20-ton (70 kW) cooling unit, for example, has a total capacity of 20 tons (70 kW) at a return-air temperature of 75°F and an RH of 45%. The same 20-ton cooling unit, however, has a sensible cooling capacity of only 17 tons at a 70-degree return-air temperature and 48% Rh (59.7 kW).

- High Relative Humidity Can Strand Capacity

Condensation can build on cooling unit coils in some IT settings due to high relative humidity (RH%). Moisture condensing on cooling unit coils produces heat, which uses some of the cooling capacity of the unit, stranding capacity that could otherwise be utilized to lower the supply air temperature to IT equipment.

- Misplaced Perforated Tiles Can Strand Capacity

In your computer room, misplacing perforated tiles reduces cooling capability. Perforated tiles or grates, for example, can be placed in an open area or a hot aisle to allow valuable conditioned air to escape the raised floor plenum. The amount of air lost through these tiles is insufficient to keep IT equipment cool. Unused conditioned air is referred to as stranded capacity.

- Unsealed Cable Openings Can Strand Capacity

Unsealed cable apertures, like misplaced perforated tiles, release bypass airflow, stranding cooling capacity since conditioned air escapes via these cable gaps and cannot be utilized for IT equipment.

Stranded capacity can be recovered without spending loads of money. All that must be done is basic and effective management and controls adjustments. These simple steps will recover stranded cooling capacity and lead to energy savings.

How To Avoid Stranded Capacity?

To avoid stranded capacity you must first identify the limiting factor and modify the capacity of the remaining 2 elements to rebalance each of the 3 defining parameters.

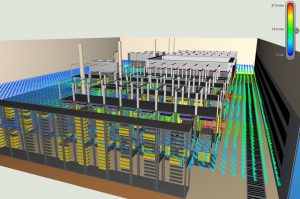

Photo Credit: media.datacenterdynamics.com

- Cooling as limiting factor

If cooling capacity is not able to efficiently cool the power load, the data center’s PUE will suffer; systems will become overheated and some of the available power will be wasted as heat output.

Underfloor cabling with limited space for cooling can contribute to stranded power capacity.

- Space as limiting factor

When physical space within a data center facility has been exhausted, modular e-houses are an efficient solution to facilitate continuous upscaling of power capacity. Additionally, the introduction of low footprint infrastructure within the data center can help to optimize the white space and eliminate wasted square footage.

- Power as limiting factor

Overbuilding of data center capacity is a major issue and is largely due to the notion that data centers need to be armed with enough capacity to meet unforeseen demand. In reality, this can lead to excessive stranded capacity which can be very costly. It is important to right-size your data center to support optimal operating efficiency where cooling, power, and space are in balance.

Preventing Stranded Capacity With AKCP Monitoring

As you can see, stranded capacity in a data center can come from a variety of places. They could account for a significant portion of the site’s cooling capacity on their own. They can add up to a significant loss of resources and money when added together, thus they must all be handled to effectively maximize a room’s cooling efficiency and capacity. Reducing stranded capacity will increase the amount of potential load that can be efficiently cooled as well as the amount of money that can be saved by making necessary airflow management (AFM) changes.

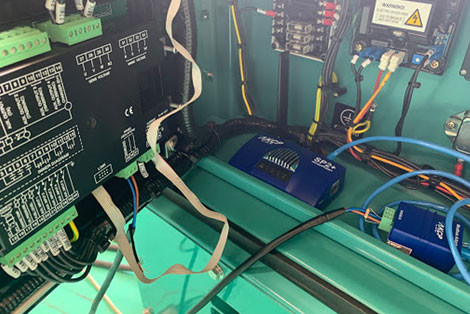

The Cabinet Analysis Sensor (CAS) features a cabinet thermal map for detecting hot spots and a differential pressure sensor for analysis of airflow. Monitor up to 16 cabinets from a single IP address with the sensorProbeX+ base units. The Wireless Cabinet Analysis Sensor is also available using our Wireless Tunnel™ Technology.

Differential Temperature (△T)

AKCP CABINET AND THERMAL SENSORS

Cabinet thermal maps consist of 2 strings of 3x Temp and 1x Hum sensor. Monitor the temperature at the front and rear of the cabinet, top, middle, and bottom. The △T value, front to rear temperature differential is calculated and displayed with animated arrows in AKCPro Server cabinet rack map views

Differential Pressure (△D)

There should always be a positive pressure at the front of the cabinet, to ensure that air from hot and cold aisles is not mixing. Air travels from areas of high pressure to low pressure, it is imperative for efficient cooling to check that there is higher pressure at the front of the cabinet and lower pressure at the rear.

Rack Maps and Containment Views

With an L-DCIM or PC with AKCPro Server installed, dedicated rack maps displaying Cabinet Analysis Sensor data can be configured to give a visual representation of each rack in your data center. If you are running a hot/cold aisle containment, then containment views can also be configured to give a sectional view of your racks and containment aisles.

Cabinet Analysis Sensor connects to AKCP sensorProbe+ base units. Extendable up to a maximum of 15 meters cable length, you can monitor multiple cabinets from a single IP address. Up to 16 sensors can be connected to a single SPX+.

sensorProbeX+

The latest generation of sensorProbe devices, in a form factor that allows for 1U, 0U, and DIN rail mounting. A low-profile design that is economical on cabinet space. sensorProbeX+ comes in several standard configurations or can be customized by choosing from a variety of modules such as dry contact inputs, IO’s, internal modem, analog to digital converters, internal UPS, and additional sensor ports.

- Every sensorProbeX+ is equipped with Ethernet, Modbus RS485, EXP, and BEB communications.

- Compatible with sensorProbeX+ EXP and BEB units, expand the capabilities of your device.

- 1U rackmount brackets, Tool-less 0U mounting, or DIN rail mounting options.

- Notification by SNMP, Email, SMS (requires optional cellular modem), built-in buzzer.

- Compatible with a wide range of AKCP Intelligent sensors.

- Start with base configuration and build up your device with the modules you need.

- Up to 80 virtual sensors.

Reference Links:

https://www.sciencedirect.com/science/article/pii/S0040162514000924

http://blog.e-i-eng.com/data-center-capacity-planning-what-is-stranded-capacity-and-how-to-avoid-it

https://www.techopedia.com/definition/29618/cooling-capacity-factor-ccf