Reduce Energy Costs

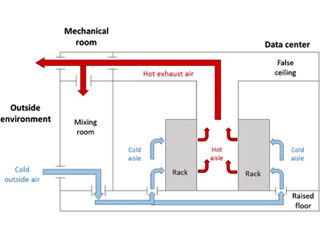

Save energy costs by focusing cooling capacity. sensorCFD provides visualization of where your air is going and where it needs to be.

Release Stranded Capacity

Maximize performance and release stranded capacity. Ensure that your air is cooling servers doing work and not being wasted cooling unnecesary space.

Monitor Thermal Risk

Protect IT equipment and monitor for hotspots in your racks. Meet ASHRAE recommendations for data center operating temperatures.

CO2 Reduction

Efficient use of cooling capacity results in improved carbon emissions. sensorCFD aids in your corporate philosophy of acheiving Net Zero emissions.

Realtime Insights

AKCPro Server DCIM provides realtime insights to data center performance metrics such as PUE. 2D and 3D heatmaps, ∆T and ∆P, humidity, security power and assets.

Return on Investment

Reduced energy costs, lower carbon footprint, increased capacity, mitigate hot spots. All of the above result in increased return on investment. Lower OpEx = higher margins.

Why Choose AKCP?

AKCP have over 30 years experience in professional sensor solutions with over 200,000 installations worldwide. sensorCFD combines our expertise in both hardware and software providing a best in class DCIM with innovative sensor technology.

Software

Central management and monitoring software for all AKCP devices. DCIM with focus on temperature and airflow analysis. 2D and 3D vizualitation of the data center with heatmaps, sensor constrained CFD and differential air pressures.

Hardware

sensorCFD combines temperature and humidity mapping, non-invasive current metering and pressure sensors. 6x temperature, 1x humidity, 1x current, 2x pressure, 3x ∆T and 1x ∆P for a total of 14 sensors per rack. Data is collected for analysis by AKCPro Server producing sensor constrained CFD models.