HVAC Maintenance Monitoring

Remote Monitoring for HVAC Technicians

Wireless Tunnel™ HVAC Monitoring System

Over 30 Years Experience In Monitoring Solutions

AKCP is the world’s leader in environmental monitoring solutions. Our Wireless Tunnel™ radio has excellent penetration within buildings and through obstructions. Our HVAC monitoring solution is suitable for all types of commercial air handlers and chilled water cooling systems.

Air Handling Unit Monitoring

The efficiency of air handling units (AHU) greatly impacts a building’s energy use. They are responsible for the control of the temperature, humidity, filtration, and building pressurization.

Monitoring temperature of the return air, outside air, mixed air, and the supply and discharge lines. A basic AHU monitoring system will analyze the thermal performance. Additional sensors for measuring static pressure, airflow, fan, and compressor kW give a more detailed analysis of the system.

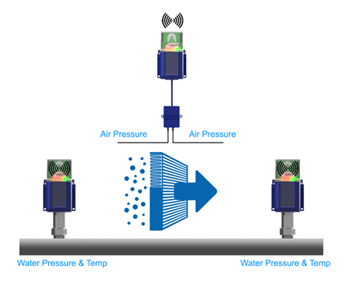

Air Handling Unit Monitoring with Wireless Tunnel™ Sensors.

Differential Air Pressure Sensor installed on the Air Handling Unit Filter. When pressure drop across the filter is high filters are dirty and require maintenance. Sensors are wireless with 10-year battery life.

Wireless Pipe Pressure Sensors monitor the water or gas pressure and temperature on the input and discharge lines from the AHU.

In chilled water cooling systems having sufficient water in the cooling tower is essential. With wireless tank depth pressure sensors, you can easily monitor and be alerted, if the water level drops below the required levels.

Flow meters can be installed to check for water loss, ensuring inflow and outflow are equal.

Diagnose Common Faults

With the air handling unit monitoring system, you can remotely diagnose faults. Common issues that can be identified are:-

– Compressor Short Cycling

– Compressor Overheating

– Over or Under Pressure

– Dirty Air Filters

Air Handling Unit Monitoring also includes control of systems. Variable Frequency Drives controlling the compressor motor can improve efficiency and lower operating costs. Utilizing a VFD to vary the motor speed also allows better matching of the hydraulic energy generated by the chiller to the demand load. This not only reduces electrical energy consumption, but can also provide more precise control of chilled water temperature. AKCP can interface to VFD’s via RS485 and control their speed based on data input from our wireless sensors.

Air Handling Unit Monitoring also includes control of systems. Variable Frequency Drives controlling the compressor motor can improve efficiency and lower operating costs. Utilizing a VFD to vary the motor speed also allows better matching of the hydraulic energy generated by the chiller to the demand load. This not only reduces electrical energy consumption, but can also provide more precise control of chilled water temperature. AKCP can interface to VFD’s via RS485 and control their speed based on data input from our wireless sensors.