A densely populated data center allows you to maximize floor space and hardware, but it brings problems with the heat generated as a byproduct of the power consumption. Air circulation strategies can only do so much and as data center energy densities increase, there will be compounded difficulties in sufficiently cooling the data center. Liquid cooling devices are not an unfamiliar option in data center cooling, but they are uncommon. While data managers may deem them risky, the current trend of higher-density racks is pushing the solution to the forefront. Traditional cooling methods are simply not capable of cooling a 40kW rack sufficiently.

Overview of Rear Door Heat Exchanges

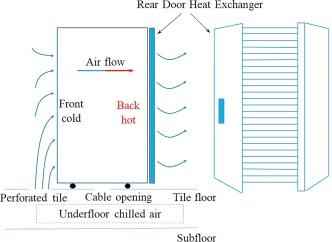

Typical RDHx systems are radiator-like doors attached to the back of racks with coils and cooling fins for heat exchange with coolant gas or water. This method of heat dissipation is very efficient because it places heat removal close to the heat source. Removing much of the heat at rack level means relatively cooler air is returned to the room, lowering the load on the CRAC or HVAC system. In some cases, the RDHx can remove sufficient heat that the air returned to the room is within acceptable limits and no further cooling is required.

Benefits of Cooling with Rear-Door Heat Exchanger

Photo Credit: www.lenovo.com

RDHx is a viable option for high-density racks. To narrow down some of the benefits it provides, here are some gains in investing in cooling with Rear-Door Heat Exchanger.

-

Heat Removal

RDHx devices, in theory, functions similarly to a car radiator. It is typical to position such a device in airflow outlets. This is where the heat exchange happens. As the device sucks in hot air from server racks, the heat is transferred from the air to the chilled water or gas flowing in the heat exchanger. This removed heat flows outside the building to another heat exchanger. Effectively the server heat is transferred from inside to outside by way of the chilled water system.

Contrary to hot and cold aisle strategies, the cooling device is placed at the very source of the heat. This reduces the chance of airflow recirculating back to the server racks. Heat dissipation is fast as air has no chance of streaming towards other outlets. A study from Lawrence Berkeley National Laboratory suggests that rear-door heat exchangers can reduce temperature conditions significantly in data centers.

-

Instant Cooling Effect

Because of its location, cooling with a Rear-Door Heat Exchanger is almost instantaneous. Putting forward this methodology encourages better running conditions for data servers. The rear door heat exchanger cuts the chance of hot air circling back in the server racks.

Operational Considerations

To maximize the capacity of a rear door heat exchanger, particular operational considerations must first be a priority.

-

Infrastructure Pre-Requisites

Installation of RDHx devices is relatively simple compared to a computer room air conditioning (CRAC) unit.

The first consideration in RDHx infra is the correct pipes for system connection. Treated water systems are linked to cooling towers, so proper routing of connecting pipes is essential. Usually, data center design considers under-floor space to provide the best avenue for such piping. Manufacturers can also offer overhead connections in some instances.

The second consideration is the presence of proper fittings in the server racks. Quick disconnects are also crucial in device removal during maintenance and upgrades.

-

Cooling Capacity

Cooling capacity is derived from a complex relationship between coolant temperature, flow rates, airflow, and surface area of the heat exchanger fins and plates. The laws of thermodynamics state that the larger the difference in temperature between two objects, the faster heat will transfer from the hotter one to the cooler one.

Coolant flow rates can range from 4 gallons per minute (GPM). Such flow rate is respective to an individual door. Flow rates can also reach over 15 GPM in denser server conditions.

Air temperature at the server outlet can be reduced from approximately 6°C to 19°C. This temperature range, however, is dependent on the pre-existing environmental conditions. Flow rates and existing server air temperature are factors in lowering the air temperature.

-

Installation Requirements

Due diligence is essential in RDHx installation. Such informed pre-inspection can save a lot of significant problems in the long run. The data gathered are vital points in installing the right RDHx.

Photo Credit: gstatic.com

-

Site Preparation

It is the primary installation activity to check the site properly. While RDHx devices are easy to install hardware, preparation measures will streamline actual installation. Some of the essential points to consider are:

- determination of system capacity (accounting chiller and cooling tower system capacity)

- location of access and connection avenues

- determination of cooling tower location

- examination of server racks to check for any obstructions or missing pieces

- removal of obstructions in the fitting area and under the floor

-

Device Installation

After going through basic preparation measures, device installation can be carried out. More than the installation, this activity accounts for optimizing the cooling capacity of the equipment as well. It only fits that efficiency measures are in place. Device installation constitutes the following basic procedure:

- installation of (1) circulating pumps; (2) flow-balancing valves and; (3) fittings

- proper routing of pipes and connecting hose

- attachment of isolation and balancing valves

- location and attachment of temperature sensors

- installation of heat exchanger doors

Following the installation of necessary items, system checks should ensue. System check does not only refer to pressure tests and leak checking but also other variables. The checkpoints should include server downtime monitoring. It is also necessary to check for pipe clearances to ensure no obstruction or possible pipe punctures.

-

Airflow Management

-

There is no way to exhaust air completely. The most logical way to manage a cooling system is to direct airflow correctly. Airflow management is a necessary method after installation. But after that, airflow management should be continuous and consistent. Some possible techniques in ensuring proper air traffic in the data servers are:

Optimizing RDHx Performance with AKCP Monitoring

To enhance the cooling Rear-Door Heat Exchanger devices, monitoring is vital. It is known that the rear door heat exchanger simplifies the data center airflow management. But even with such an advantage, constant monitoring is still a sound supplement to it. Monitoring is crucial, especially in newly installed data center settings. Some points to ponder in creating a monitoring system for RDHx performance are the following:

Power Monitoring Sensor

- scan proper locations for temperature sensors

- inspect airflow leakage and recirculation

- verification of airflow temperature and pressure (essentially in air inlets and outlets)

- probing of air temperature in RDHx outlet

- survey coolant flow rates

- confirmation of inlet coolant temperature

- review and explore parameter thresholds

The data servers and RDHx devices are now interlinked systems. It only fits to monitor them as one. Of course, there will be hardware monitoring specifications. But a comprehensive monitoring system should track both technologies.

This kind of technology system needs a comprehensive monitoring solution. AKCP has a range of monitoring technology that fits the bill. From basic temperature and air humidity sensors to server racks thermal mapping sensors will give a thorough perspective in tracking differential temperature and pressures in your server racks.

Power Monitoring

The AKCP Power Monitor Sensor gives vital information and allows you to remotely monitor power eliminating the need for manual power audits as well as providing immediate alerts to potential problems. It has been integrated into the sensorProbe+ and securityProbe’s web interface with its own “Power Management” menu, allowing multiple three-phase and single-phase Power Monitor Sensors to be set up on a single sensorProbe+ or securityProbe depending on which readings are required. Power meter readings can also be used with the sensorProbe+ and AKCPro Server lives PUE calculations that analyze the efficiency of power usage in your data center. Data collected over time using the Power Monitor sensor can also be viewed using the built-in graphing tool. Combining this durable Power Monitor Sensor with the sensorProbe+ and securityProbe creates an IP-enabled power monitoring capable of monitoring and measuring:

- Phase Line Voltages

- Current

- Power Factor

- Active Energy

- Active Power

Thermal Map Sensor

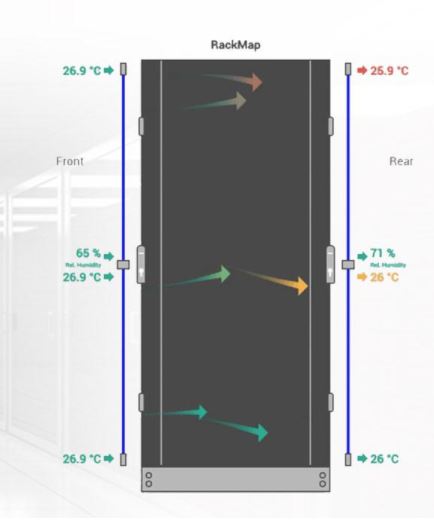

Datacenter monitoring with thermal map sensors helps identify and eliminate hotspots in your cabinets by identifying areas where temperature differential between front and rear are too high. Thermal maps consist of a string of 6 temperature sensors and an optional 2 humidity sensors. Pre-wired to be easily installed in your cabinet, they are placed at the top, middle, and bottom – front and rear of the cabinet. This configuration of sensors monitors the air intake and exhaust temperatures of your cabinet, as well as the temperature differential from the front to the rear.

For Wireless Monitoring

Power Monitoring

3x AC Voltage Inputs up to 487 VAC with 4x current transformer inputs, up to 50A max per phase. Monitor power with billable grade accuracy over Wireless Tunnel network with reports and alerts. Works with all Wireless Tunnel Gateways.

AKCP Wireless Sensors

Thermal Mapping of IT Cabinets

Wireless thermal mapping of your IT cabinets. With 3x Temperature sensors at the front and 3x at the rear, it monitors airflow intake and exhaust temperatures, as well as provides the temperature differential between the front and rear of the cabinet (ΔT) Wireless Thermal maps work with all Wireless Tunnel Gateways.

Thermal Maps are integrated with AKCPro Server DCIM software in our cabinet rack map view.

Maximizing the Cooling Benefits of RDHX

Cooling with a rear-door heat exchanger is a game-changer on data center operations. It promises cost-efficiency while building higher output turnovers. In the end, data centers are intensive systems that are making the operational life of organizations easier.

But the complicated functions and requirements in operating a data center are enormous. RDHx system is one way of uncomplicating the process. Ultimately, your data center should be powered with a sound cooling device and comprehensive monitoring system geared towards optimum performance.

Reference Links:

https://datacenters.lbl.gov/sites/all/files/rdhx-doe-femp.pdf

https://teamsilverback.com/how-rear-door-heat-exchangers-solve-the-high-density-data-center-problem/