The demand for high computing capacity changed the standard for data center operation. It sets a more complex environment making the Computer Room Air Conditioning (CRAC) units alone an insubstantial solution. Inadequate rack cooling has become a prevalent issue among data centers today. A recent study found out that 8 out of 10 facilities experience overheating of server racks. This issue leads to data center administrators’ worst nightmare – downtime.

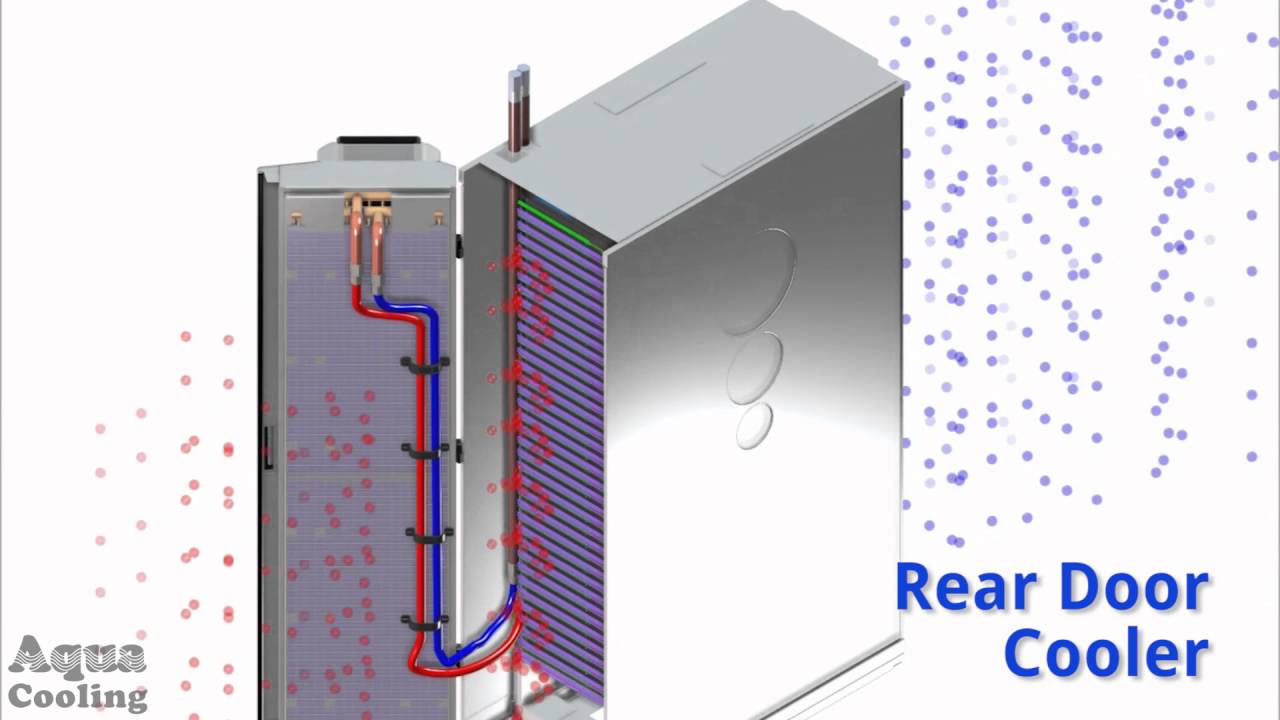

Embracing the rear door heat exchange (RDHX) system can help the data centers keep up with the increasing rack density. A heat exchange device is installed on the rear door of the server racks and absorbs heat. It will be later transferred to the heat exchanger matrix or coil. It’s like addressing two problems in one solution – inefficient cooling and huge energy consumption.

What is a High-Density Server Rack?

A high density rack is one where many of the U’s are filled with power hungry servers. The height of one unit (1U) is 1.75 inches, so it described rack density in terms of the number of units. But in a broader sense, rack density refers to the average amount of power needed by every rack. It can be calculated in watts per square of the floor space.

Understanding the rack density is the key to choosing the right cooling solution. Having high-density server racks means that the data center has more capability to handle a large amount of data and computational capacity. The typical rack density of 3-5kW in the past has increased to more than 7kW. This is the equivalent of more than 150kW per square foot. A rack of 7kW or more is considered high density.

However, constantly evolving technology makes the definition of “what a high-density rack is” change. The standard of a high-density rack this year will surely be different in next coming years.

How RDHX Rack Cooling Works?

Photo Credit: i.ytimg.com

In a case study by Lawrence Berkeley National Laboratory, rear door heat exchangers were used as a rack cooling solution. Attached to the exhaust of the rack, they are connected to a centralized chilled water system. It removes the heat from the exhaust air of the rack and delivers cooler air into the racks using the fans. RDHX system can be an active device with built-in fans or passive devices that depend on the server fans to exhaust the air.

Pump refrigerant heat exchanger with a chiller is another option. This generates the same efficiency as the active RDHX. Concerns regarding availability and the drive toward higher densities have introduced this system within the industry. The heat exchanger and the pump isolate the cold air from the chiller. This system also uses a refrigerant or any other non-conductive fluids like Flourinert. It is pumped through the system without the use of a compressor. However, this could be an additional expense as pumps and heat exchangers are added.

RDHX is workable both for newly designed and already established data centers. The device is included in building a new racks enclosure. It can also improve the cooling system by adding it to the existing high-density racks. Moreover, it can deliver sufficient cooling while getting rid of the complex under-floor air distribution.

Energy Efficiency

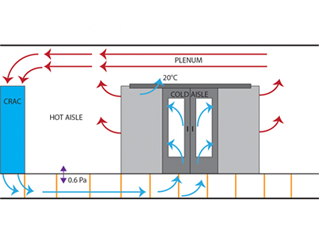

Photo Credit: www.upsite.com

High-density racks maintaining thousands of servers consume massive energy. Worldwide data centers consume around 205 terawatt-hours which is equivalent to 1% of the worlds total energy use. This points out the need for an energy-efficient rack cooling solution. The rear door heat exchanger is one of these.

Lawrence Berkeley National Laboratory (LBNL) uses Passive RDHX on its data center. The solution shows different ways to save energy within the LBNL facility. It does not require electricity for it to work. This device can consume minimal energy since it can operate at higher chilled water temperatures. With this, the coil works less while providing enough cooling. Also, the cooling tower water treatment system can lessen the use of chiller energy during the cooling process. If maintained in the long run, this will cause a significant reduction in operating expenses.

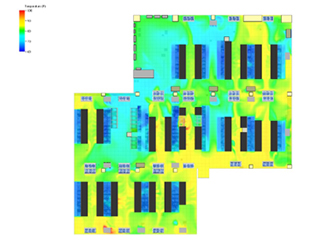

Cooling Efficiency

The rear door heat exchanger provides superior cooling efficiency as it is installed directly into the server racks. With heat removal near the heat source, air temperature lowers before it ejects air to the data center space. With this, cooling the air does not require the huge CRAG units on the floor space. Moreover, water chilled cooling system is about 3,500 times more effective than air by volume. Cambridge University data center realized 98% power efficiency using RDHX cooling solution. Recently, it earned a PUE of 1.14 to 1.17 despite increasing IT Load.

Another gain for this solution is the easier way of dealing with hotspots. RDHX makes sure that the cold air is delivered to the necessary areas within the rack. It alleviates inadequate/excess and improper distribution of cooling causing airflow problems.

Common Problems in Rear Door Exchange Heater

The efficiency brought by RDHX as a rack cooling solution is unquestionable. However, other data centers still see it as a “no-no” when they’re asked about integrating it into their operation. These are issues that keep RDHX from being fully accepted in the industry.

-

Water Leakage – There is a risk of water leaks. For instance, IMB RDHX holds six gallons of water supporting a flow rate of up to 10 gallons in a minute. In this case water leak detection sensors would be essential.

-

Air Leakage – For data centers with UFAD, air needs to be distributed properly. This air may also leak as the cabinet doors are not fit tightly. This will be followed by an increase in inlet temperature. This should be considered as leakage mitigation is more effective than reducing temperature. Cabinet analysis sensors with differential air pressure can detect these problems.

Airflow Management Rear Door Exchange Heater

Air circulation is the most important player in implementing Rear Door Exchange Heater or any other rack cooling solution. Its impact greatly depends on the airflow that is supplied and exhausted by the servers. Therefore, every data administrator needs to create a result-driven airflow management plan. This will let them achieve overall efficiency as a return for the capital invested in the solution.

How Do Sensors Work in RDHX?

Power Monitoring Sensor

Power Monitoring Sensor

The AKCP Power Monitor Sensor gives vital information and allows you to remotely monitor power. This eliminates the need for manual power audits as well as providing immediate alerts to potential problems.

Power meter readings can also be used with the sensorProbe+ and AKCPro Server lives PUE calculations that analyze the efficiency of power usage in your data center. Data collected over time using the Power Monitor sensor can also be viewed using the built-in graphing tool.

Combining this durable Power Monitor Sensor with the sensorProbe+ and securityProbe creates an IP-enabled power monitoring capable of monitoring/measuring:

- Phase Line Voltages

- Current

- Power Factor

- Active Energy

- Active Power

AKCP Cabinet Analysis Sensor

Airflow and Thermal Mapping for IT Cabinets

The Cabinet Analysis Sensor (CAS) features a cabinet thermal map for detecting hot spots and a differential pressure sensor for analysis of airflow.

Differential Temperature (△T)

Cabinet thermal maps consist of 2 strings of 3x Temp and 1x Hum sensor. Monitor the temperature at the front and rear of the cabinet, top, middle, and bottom. The △T value, front to rear temperature differential is calculated and displayed with animated arrows in AKCPro Server cabinet rack map views.

Conclusion

The rack densities are predicted to grow in the coming years. By then, CRAC units may not be enough. The rear door heat exchanger can be a viable solution to address the lacking capacity of the CRAC units. As mentioned, it can maximize cooling while minimizing the cost. This has been the dream of every data center administrator. However, failing to recognize the risks is a weakness of this solution. It is important to identify, monitor, and report all hazards to achieve a reliable data center.

Reference Links:

https://www.datacenterknowledge.com/archives/2017/05/22/rdhx-systems-help-with-high-density-data-center-cooling

https://datacenters.lbl.gov/sites/all/files/rdhx-doe-femp.pdf

https://www.opencompute.org/documents/acs-door-hx-open-compute-requirements-for-open-rack-rev0-95-1-pdf

https://www.missioncriticalmagazine.com/ext/resources/whitepapers/shlomo-WP-RDHx-Cost-Effective-Alternative-to-CRAH-120811.pdf

https://www.vertiv.com/49cfee/globalassets/shared/liebert-dcd-passive-and-active-brochure_0.pdf