What are rack blanking panels, and do they deliver results? Heat movement is vital to data centers. Ideally, heat should be exhausted out of the facility. But heat might travel to places where they expose computing units to high temperatures.

As a solution, many data center facilities use the cold aisle and hot aisle isolation. They also enclose racks in containments so that heat and cold air can travel separately. But it’s not enough. Computers emit heat that can still recirculate to empty spaces in the racks. These can result in heated adjacent servers. To prevent this, the gaps in empty racks are covered with materials called rack blanking panels.

In this article, we’ll describe the importance of rack blanking panels and how they can protect the servers from recirculating heat, and ultimately cut energy expenses.

What is a Rack Blanking Panel?

A rack blanking panel is sometimes referred to as a closeout filler panel. It’s a rectangular piece of metal or plastic that can be screwed on an empty spot on the rack. A blank panel covers the unused space until a server is set to occupy it. At that point, the blanking panel needs to be taken out and the server comes in. This material is used on all the empty rack spaces in the data centers.

Server rack blanking panels come in many sizes depending on the size of the empty space. The smallest is 1U and it’s equivalent to the size of one rack unit or one server. Some can be as large as 6U’s.

When blanking panels are installed correctly, they prevent hot air from recirculating back to the gap. Without rack blanking plates, heat may travel to empty spaces heating the closest servers above and below. Two things can happen. Either heat can damage the servers or fans might have to work harder to eliminate the heat. Both will result in increased energy usage and lower efficiency.

Blanking panels can work even better with the aid of other solutions in data centers. Let’s discuss one by one and how blanking helps all of them.

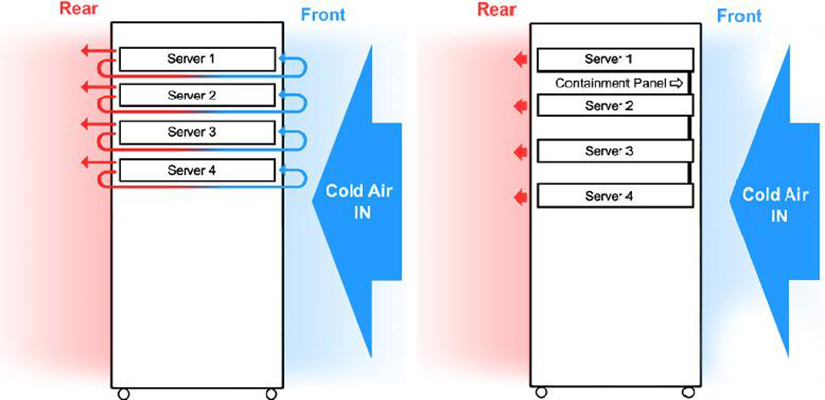

A hot aisle or cold aisle setup has tremendously increased the energy efficiency of data centers. This method is arranging the racks in a way that the exhaust air face one aisle and the cold air face the other aisle. Not letting the hot and cold air mix is the principle behind this design. The parts of the servers that face the hot aisle are the return ducts and the exhaust fans. The rack air intakes can be found in the cold aisle.

A hot or cold aisle orientation still lacks complete control of air mixing. Containments segregate the aisles even further. It protects either the hot or cold aisle, depending on the choice of the management, from unnecessary recirculation and redirection of heat and cold air. This means cold air is directed to the computers and the hot air flows to the exhaust, hence, no unnecessary energy waste.

Are Blanking Panels Proven to Work?

The question is, do they really work? Or Is it just a waste of money and time? To answer this, Dell, one of the world’s biggest data center companies, researched the effectiveness of blanking panels and published the results in their white paper.

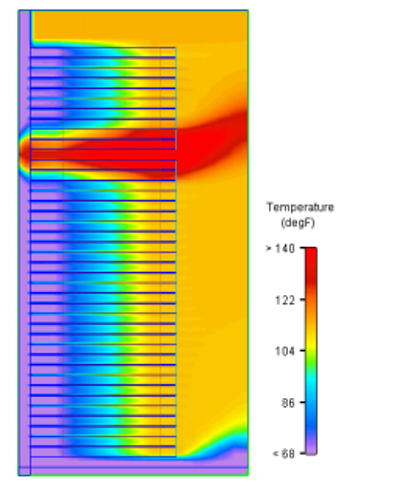

Their conclusion? It works. Using Computational Fluid Dynamics (CFD), they traced the movement of heat in an uncovered rack space. The computerized image below shows the side view of the rack. It’s evident that temperatures exceeding 50°C (122°F) can recirculate to the empty 1U space and then heats up the adjacent servers.

This process can prompt the fans of the nearest servers to overwork to compensate for the additional heat. Again this consumes more unnecessary energy that could have been avoided with a simple filler panel.

Let’s compute for the additional energy use. In this study, Dell used PowerEdge R610 servers. This server typically consumes 22 watts of energy. Using the facility’s Power Usage Effectiveness (PUE) or simply the ratio of the energy spent to the actual energy used by the servers, and the energy cost of $0.10/kW-hr, the additional annual energy required to power these server fans costs $39. The cost can even rack up to $300 for older units of fans and servers.

This study focused on a single rack unit. Several empty racks without blanking panels can contribute to high temperatures in the data center overall. The facility will then be compelled to operate at even lower temperatures. This might seem unnoticeable for months, but annually speaking, this is a dramatic increase in energy use.

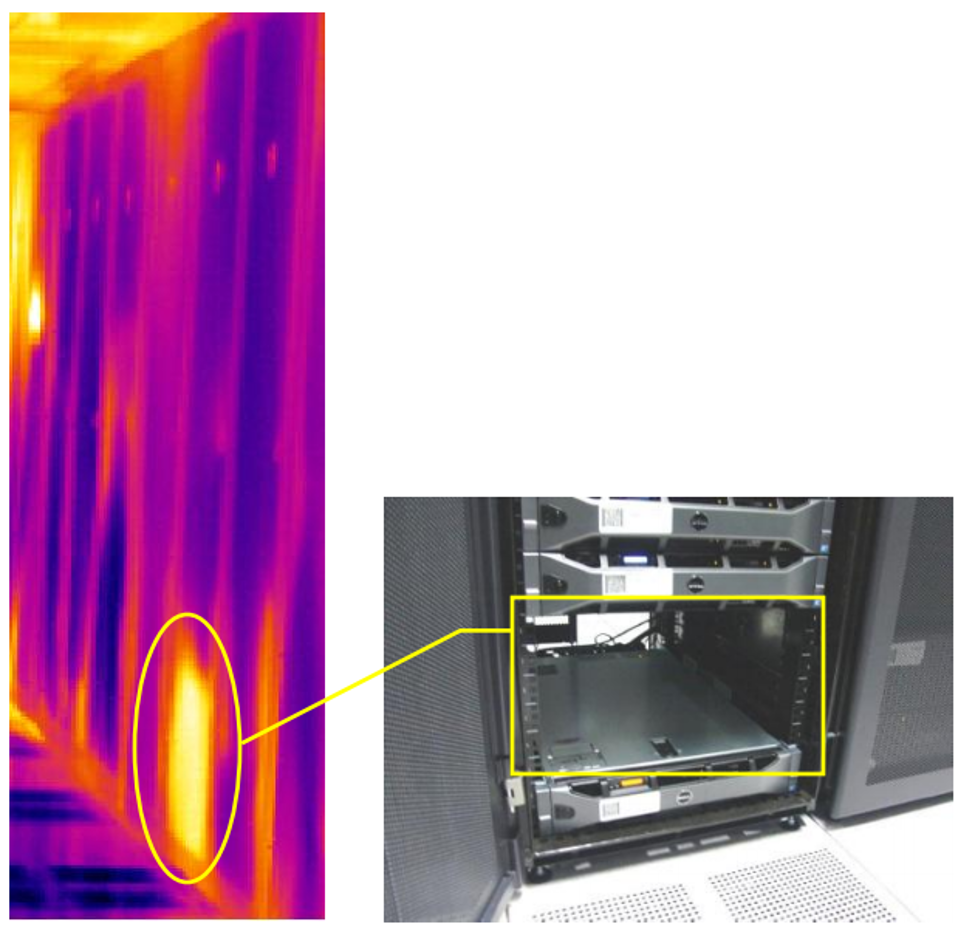

Although fans can compensate for the heating of adjacent servers, empty spaces can be a ground for the increase in inlet temperature. The nearest servers will get hot faster than the other servers and can get damaged over time. The image below shows how heat can concentrate on the empty rack spaces. Also notice how filled rack units have no visible high temperatures.

How to Properly Use Rack Blanking Panels?

The results of the study recommend the use of blanking panels on all empty rack spaces of data centers. It’s not just for large gaps. Since these plates come in all sizes, even the smallest gap has its custom-sized panel.

Some people think it’s better to leave spaces between servers so they don’t heat up easily. As for Dell, it’s not recommended. A better practice is to pile servers closer together. The pressure propels the air to travel through the gaps. A study found that the leaks between blanking panels have a more tremendous effect. Even gaps of the same sizes still allow the air to travel in short distances affecting the adjacent servers. Compared this to where servers are piled on top of each other. The air will pass just through them and not heat up the machines

It’s also worth mentioning that this material won’t block all the heat. Despite its good sealing capability, it still leaves a very small gap around each piece of equipment due to its fit within the U-envelope. When considering a small percentage that can pass through such a small space, it’s just a minor issue and won’t affect energy use.

Installing blanking panels can be time-consuming. But its energy-saving potential is still worth it.

The design enables it to just snap in and out of the square gap. But it also provides a stable option by screwing it in place. The largest size is 6U meaning six rack units. And because it’s advisable to pile the servers together, it’s easier to cover big gaps as well.

Is it Costly?

Now that we know how effective blanking panels are, it wouldn’t matter how much they would cost. It would still be worth it. Blanking panels are not even that expensive. And of the two material choices, we can opt for plastic which is cheaper. If choosing to buy in bulk, most manufacturers would also give discounts.

And if blanking panels are not really part of the budget, then you can improvise. There are perforated die-cut plastic sheets that are even less expensive. Some people have created different blanking solutions that mimic the characteristics of the material. Whatever is the choice, just cover the gaps. It will help in many ways but most importantly in energy expenses.

Conclusion

Blanking panels are not the only solution responsible for attaining energy-efficient data centers. Hot and cold aisles, containments, cold ambient temperature are only some of the many solutions that a data center company can incorporate in their facility. Blanking panels, however, are really proven to deliver effective results at a cheap price and minor changes.