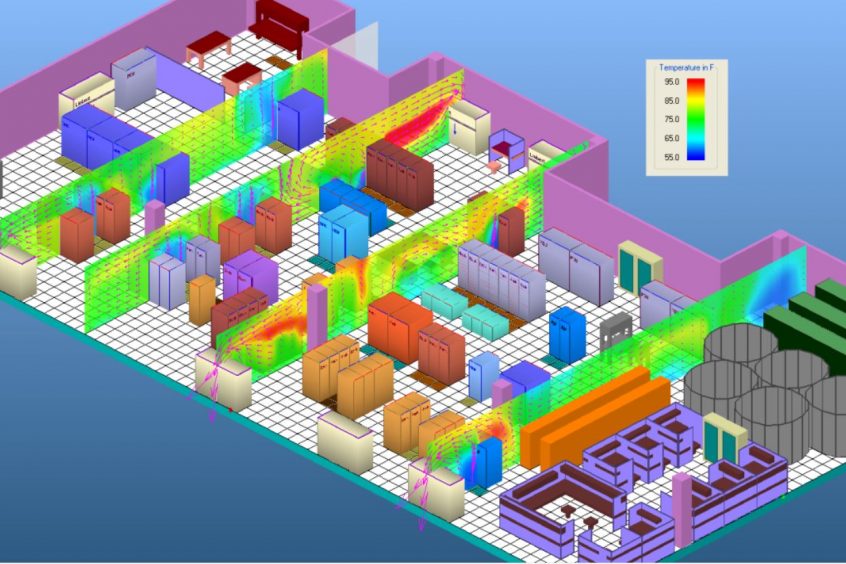

Cooling IT hardware in a data center is a function that needs the utmost priority. However, cooling through airflow management alone is not sufficient. One must consider the complex nature of the IT environment. High-density IT infrastructure requires critical management and monitoring to sustain a data center. Computational Fluid Dynamics (CFD) analysis is used for data center airflow management and design.

Airflow management is, in principle, controlling airflow and navigating it to the proper equipment. This can prove hard for data centers with little know-how in airflow management. If the airflow is not managed properly your data center is living on borrowed time. It will one day suffer a catastrophic event that will result in downtime or damaged IT equipment.

The Science In CFD

An application that can aid better analysis of airflow in the data center is computational fluid dynamics (CFD). It performs thorough analysis using the mathematical principles of fluid mechanics and the corresponding heat transfer prompted by fluid behavior. The science of CFD can predict the airflows path through the data center and the amount of heat that is removed.

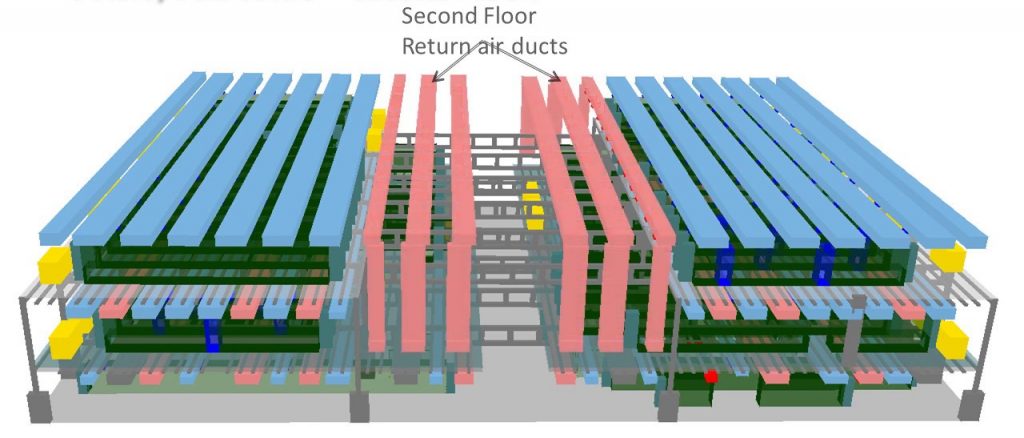

CFD starts with a model of the data center, walls, floors, and the arrangement of racks and CRAC units. The heat generated by the IT equipment, which is derivative of the power consumed and the cooling system capacity is input into the model. CFD modeling and analysis will aid in:-

- Better Design Layout

- Easy Maintenance and Repair

- Improved IT Troubleshooting

- Enhanced Retro-Commissioning Efforts

How Does CFD Utilize the Modeling Analysis?

CFD works by dividing the 3D space into smaller units. This way, it can calculate smaller values of predicted speed, rotation, and direction of fluid flow. Such small values raise accuracy levels consequently. CFD as a science function in software. It can model the following physical attribute of a fluid:

- Density

- Thermal Inertia

- Viscosity

- Elasticity

It can also consider the adjacent elements predicting how they interact and passing their behavior from one component. As such, the prediction of heat transfer is satisfactorily feasible through CFD.

Where Can CFD Work?

Information gathered from CFD oversees path solution to airflow. In the context of a data center, computational fluid dynamics capacitates the simulation of changes and understanding the relative implications of perceived implementation.

- CFD Works As A Service

Because CFD is built-in software, it can run on any other computer. Like any other software, CFD also has licensing keys to take advantage of its analytic features. It is rather advantageous for big-scale data centers to take hold of a CFD license. The cost associated with the computational fluid dynamics service will warrant more considerable benefits to a highly dense IT system. It should also be a consideration that the modeling of data center airflow is periodic. No matter how regular it is done, the periodic interval is quite far in between. As much as CFD can enhance better data center operations, it may just be a more extensive overhead investment for smaller data centers. - Prediction Tool

The main highlight of using CFD is its capacity to predict the unexpected. Because it models and observes particular IT implementation, it has granular visibility of how things should happen. Its prediction accuracy is also suitable for any data center layout. Because each data center is unique, CFD adapts to what is programmed for modeling. Its capacity to divide smaller spaces enables it to further immerse the inspection process to better illustrate data center airflow dynamics. - Pre-Requisite To New Equipment Integration

It is often hard to deduce how much equipment should a data center hold. Despite the demand variables, integrating the correct number of IT equipment is still a challenge. Logically, airflow should be adequate once data centers hold a higher number of IT. This is because the cooling demand is higher as well. It is crucial to understand how airflow will dictate distribution through the data center layout. Taking note of recirculation pathways is also a critical airflow management checkpoint. Flow rate measurement is directly relevant to a successful airflow management output. The information leveraged from CFD analysis can provide a better understanding of how to put things in the data center properly. It will reduce any premature IT equipment failure and will guarantee a longer running life. - Taking Note Of Hotspots And Addressing Them

One crucial element to negate in airflow management is reducing hotspots. In essence, CFD can identify such presence and provide knowledge on a possible countermeasure. For instance, the distance from a hot aisle to a CRAC unit can gauge the likelihood of hot air re-entering. CFD can also be a valuable source in identifying excess heat at the rack rows end. It is the best tool to check IT equipment situated in the end rows, potentially receiving lesser air. In a way, it collectively outlines all possible units that will be affected by hotspots. Having the basic information on these things will adequately improve airflow management to consider IT equipment positioned at the end. - Providing Optimum Cooling Condition

The optimum cooling condition does not only pertain to the capacity of the cooling system to negate heat from the data center. It also takes into consideration sustainable cooling practices to operate data centers at optimum conditions. Energy consumption is the most practical way of gauging if data centers are running under optimum cooling output. Understanding how airflow distribution works in a data center makes it easy to adjust changes for implementation. In line with this, CFD provides a precise ability to model these changes and optimize cooling capacity under lower energy input.

Is A Model Close To Reality?

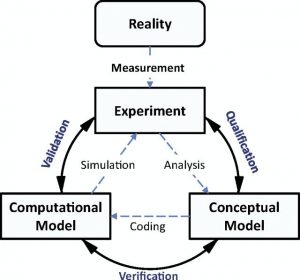

Photo Credit: CHAM Youtube Channel

No, a model will almost always be not precisely the reflection of reality. In the case of CFD models, it will not be 100 percent accurate. What the CFD model provides is a snapshot that depicts the closest possible scenario in a specific circumstance. As such, CFD is a calculated proof of describing airflow dynamics given a particular data center design.

However, we should also consider that an exhaustive model will result much closer to reality. As such, CFD will work best if comprehensive assumptions are taken into consideration. There is a range of deductions that can be outlined but will be limited through the CFD model.

- Random variations of airflows cannot be modeled through CFD;

- Variation in the fan speed with ICT load is dependent on a specific server model with variations on kW load

- CFD system is limited to modeling under individual server premise

Despite the many limitations, CFD models can picture the best possible design implications. The current software will wait until the system is ripe to load dynamic monitoring and evaluation infrastructure.

Pushing the Benefits of CFD Beyond Implementation

It is established that CFD works best in the planning stages. While it can iterate redesign and reconfigurations, the value of CFD is best realized during the initial staging of data centers. Leveraging from the CFD information, better data center design can be put forth. But operating the data center continuously will have its drawbacks. Such drawbacks will result in downtime if left unentertained.

After implementation, it is essential to follow through with the best-case scenario given by CFD analytics. It is best to comprehensively supplement it with monitoring solutions to cover all bases in a data center operation. One of the many ways to do it is by incorporating thermal mapping sensors in the facility.

Wireless Thermal Mapping

Wireless Cabinet Thermal Map

Wireless thermal mapping of IT cabinets can monitor air flow intake and exhaust temperatures. It can also measure relative temperature differential in the front and rear parts of the IT cabinet. AKCP thermal mapping sensor can function to provide such visibility. But more than that, AKCP sensors can interface with Wireless Tunnel Gateways ensuring a centralized monitoring system. The wireless tunnels build upon Lora technology designed to provide instant notification and on sensor threshold level checking. When the deployed sensors connect to the AKCPro server, it can function as a robust monitoring platform that will carry out the following:

- Drill Down Mapping

- The Report, Graphing, And Alert Notification

- Video Synchronization

- Access Control Administration

- Asset Tracking

- Cabinet Rack Maps

These monitoring solutions capacitate an intelligent aisle containment building on the precise models of CFD. Cabinet thermal mapping and environmental monitoring will take their cue from the analytical implication deduced from CFD calculations.

Anchoring CFD in Data Center Operation

Engineers understand that airflow and heat transfer is significant component of any IT operation. CFD can boost these capacities to think more about thermal performance, air distribution, and IT infra resiliency more than optimal location and retrofitting the design.

The critical nature of data center operation involves risks that, when left unguarded, will balloon into more significant issues. The power of CFD provides possible checkpoints before the design proposition. In a way, the analysis provided by CFD will validate designs that will best fit the air distribution criteria. An initial analysis of the data center will save many additional burdens when operations come into full blast. It is only fitting that CFD should be an anchor to any data center planning.

Reference Links:

https://www.coolsimsoftware.com/Portals/0/PDF/WP102_Making_Informed_Decisions.pdf

https://www.esmagazine.com/articles/101279-the-benefits-of-indoor-cfd-modelling-in-data-center-applications

https://www.datacenterdynamics.com/en/opinions/how-useful-is-cfd-for-data-centers/