Indoor Air Quality Monitoring is often associated with human health, well-being, or comfort. However, in data centers, IAQ is pertaining to the “health” of critical information technology (IT) and datacom equipment. Air Quality Monitoring is important in data centers to keep possibilities of corrosion in check.

The inevitability of outdoor air pollution has been a reality that we have had to deal with on this planet. It has existed since the advent of the industrial age. In recent years, data centers in urban locations are experiencing higher equipment failure rates due to the effects of gaseous pollutants, higher temperatures, and fluctuating humidity inside the data center. As the years passed, many companies learned the importance of air filtration systems in avoiding the disastrous effects of poor indoor air quality on their data centers. There is also the air quality monitoring system that provides real-time updates to ensure that the air filtration devices are working at optimal efficiency.

Data centers need clean air for their servers and computing equipment to operate. Impurities and particulates in server rooms can cause corrosion and damage.

What is Data Center Corrosion?

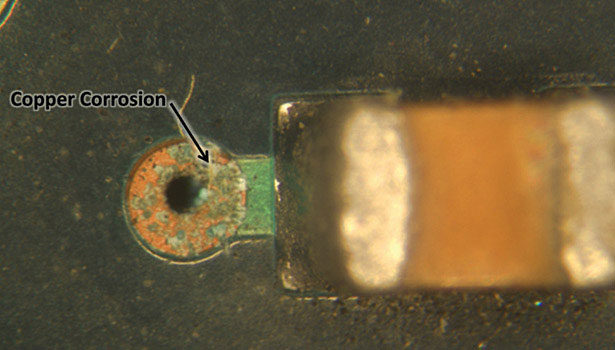

Data Center corrosion is defined as a form of chemical contamination. This form of contamination is brought about by the vapor of harmful and corrosive gases. They come from pollutants that make their way into air-conditioned server rooms, control rooms, switchgear rooms, process control, and signal switching rooms in data centers. These gases can degrade the service life of the mission-essential gear. They also bring about a phenomenon called micro-electronic corrosion. This occurrence can lead to equipment failure and increased downtime of the facility.

A data center with maintained standards of indoor air quality usually has filtration devices to catch fine particulates. It also has top-of-the-line temperature and humidity control systems.

Electronic equipment is comprised of a complicated assembly of metallic and non-metallic parts. These components are vulnerable to corrosion. If allowed to go unfixed, they can damage electrical components like:

Film Disks

Collected data could be damaged at the reaction site. Also, as reaction residue builds up, mechanical malfunctions can happen on data tracks that have not yet been corroded.

Edge Connectors

These connectors are located on the circuit boards. They are manufactured from copper with gold or copper-plated substrate. Corrosion can cause interference in the connection points. The presence of corrosives may also impede efficient data transfer.

Disk Drives

The configuration of disk drives is such that they are especially vulnerable to electronic corrosion even in an indoor atmosphere.

Molecular gaseous pollutants pose a danger to both IT and sensitive electronic equipment. Gases such as Sulfur Dioxide and Hydrogen Sulfide are known to be the most notorious for corroding electronic equipment. These two gases alone do not pose that much of a threat to silver or copper. But the combination of both with ozone can spell total disaster for electrical gear. The rate of corrosion of copper depends on the factor of humidity, but with silver, it is less so. These corrosive gases in a data center environment not only pose a threat to electrical equipment but the health and well-being of the employees as well.

Photo Credit: www.esmagazine.com

How Does Indoor Air Quality Impact Data Centers?

- Dangerous chemicals such as Sulphur and Nitrogen Oxides, along with other pollutants found in the atmosphere can cause corrosion. This then causes failure of the electronic and computing components of data processing gear. These destructive gasses are the result of the burning of fossil fuels.

- Board Level Corrosion manifests itself in several ways. Some of these manifestations include contaminated solder joints, corrosive shorting across conductive pathways, and whisker growth. This sort of corrosion is brought about by particulate matter and can lead to electrical shorts in contact points. The total effect is the reduced operating life of data center gear.

- There is also a risk to the human element in a data center. This comes in the form of Volatile Organic Compounds (VOC) such as fluorine. These compounds are usually found in power and communication cables that line the data centers. These chemicals can harm the human respiratory system as well as the eyes. This factor is another reason why the indoor air quality of your data centers may not be healthy.

How to Quantify if Your Data Center has Acceptable Indoor Air Quality Levels

-

G1- Severity Level Mild

This is a data center atmosphere where all preventive measures to filter out indoor air pollution have been implemented. There is vigilant and constant monitoring for pollutants and harmful gases. Corrosion has also been eliminated as a factor for equipment failure.

-

G2- Severity Level Moderate

This is a data center atmosphere where there is a minimal amount of indoor air pollution and corrosion. But these amounts are still within measurable and manageable parameters. Yet, these corrosives and pollutants may now begin to show a small effect on equipment dependability.

-

G3- Severity Level Harsh

This is a data center atmosphere where there is a high risk that a corrosive attack will happen. These harsh levels now need unrelenting vigilance in environmental monitoring. They also prompt the use of designed and packaged equipment.

-

GX- Severity Level Severe

This is a data center atmosphere where only specially designed and packaged equipment is expected to survive. Specifications for equipment at this level are a matter of negotiation between user and supplier.

Monitoring IAQ Levels in Data Centers

AKCP Wireless Air Quality Sensor

The sensor detects various Metal Oxide (MOx) gases, displaying the value as a VOC Index. Examples of these gases are:

AKCP Wireless Air Quality Sensor

- Acetone (eg. paints and glues)

- Toluene (eg. furniture)

- Ethanol (eg. perfume, cleaning fluids)

- Hydrogen Sulfide (eg. decaying food)

- Benzene (eg. Cigarette smoke)

The VOC Index is a logarithmic scale that is relative to the typical indoor gas composition over the past 24 hours. With a range of 0 to 500, the typical value for a normal environment is 100. Values greater than 100 indicate worsening air quality with a higher concentration of metal oxide gases over the past 24 hours. Values lower than 100 indicate improving air quality.

Air Particles

Detection for 5 different sizes. PM0.5, PM1.0, PM2.5, PM4 and PM10. The sensor is able to measure the mass concentration of particles in the PM1.0 to PM10 range and particle number concentration in the PM0.5 to PM10 range. The typical particle size is also measured. This measurement is based on the average size of the current sample.

An air particle sensor is utilized during indoor air quality (IAQ) assessments of clean rooms and workplaces. The specific type of particles is not detected, but it identifies the quantity or mass of airborne particles. These air particles could be sourced from:

- Exhaust smoke

- Airborne dust particles

- Pollen

Airborne pollutants can be a health hazard, and result in sneezing, headaches, asthma, and so on. In addition, during many agricultural and industrial processes, airborne dust can be a serious hazard forming combustible dust clouds.

Conclusion:

Data centers store the invaluable equipment and data of the business. It is important to always be on the lookout for all the factors that affect its efficiency, especially if this factor can cause disasters like corrosion.

If ever data center’s air quality needs to be tested and monitored, don’t hesitate. Monitoring systems might be a little expensive. But, it is nothing compared to tons of dollars of expenses with the repair or replacement of the equipment. In the end, the efficiency of the data center is the most important.

Because prevention is always better than cure. Do not let poor indoor air quality affect uncertainties in the business.

References:

https://www.dqindia.com/protect-data-centre-threat-electronic-corrosion-abrupt-failures/

https://www.purafil.com/isa-environmental-classifications-changes-new-requirements/#:~:text=Severity%20level%20G1%20%E2%80%93%20Mild%3A%20An%20environment%20sufficiently,may%20be%20a%20factor%20in%20determining%20equipment%20reliability.

https://www.downtoearth.org.in/news/all-about-effective-air-quality-monitoring-46494#:~:text=The%20automatic%20or%20Continuous%20Ambient%20Air%20Quality%20Monitoring,online%20through%20a%20digital%20display%20board%20to%20public.