Importance of Warehouse Temperature and Humidity Monitoring

Many warehouse owners overlook the importance of monitoring temperature and humidity in the warehouse. Failure to monitor the environment in the warehouse area leads to unexpected expenses. Loss of inventory due to damage caused by excessive humidity, temperature, or water leaks results in lost inventory.

What Damage Can Be Caused?

What Damage Can Be Caused?

Excessive humidity in warehouse areas can lead to mildew and mold growth on products, shelves, boxes, and walls. Condensation causes rust and accelerates the corrosion of metal parts. Increased insurance costs due to customer claims or returns.

Humidity changes over the course of the day. Often daytime humidity can be in the 30% range. However, at nighttime, it can easily increase to 70%-80%. This means a 24/7 monitor of humidity is essential, with alerts when it is out of prescribed range.

High temperatures can also lead to spoilage of products, especially those sensitive to environmental conditions such as pharmaceuticals, or foodstuffs.

When the quality and purity of the products rely on correct storage it is critical that a warehouse temperature and humidity monitoring system is employed.

Mold Growth

Mold is a type of Fungi, some are edible such as mushrooms, and others are used in the baking of bread and brewing beer, Yeast. Most Fungi live off of decaying biological matter and are responsible as one of the main agents for recycling dead plant and animal matter.

Some Mold however can be damaging to health. Spores from mold in enclosed spaces have been attributed to respiratory illnesses.

Mold spreads through the release of spores, which are microscopic material and almost impossible to eliminate. They travel through the air, settle on a suitable surface and begin to grow.

When spores settle on a surface, in order to thrive there should be sufficient food to sustain the fungi. Any organic substance can support mold growth. Mold can attack the most common materials used in warehouse packing materials such as wooden crates, and cardboard boxes. Eliminating all sources of food for mold is also an almost impossible task.

The two important environmental conditions for mold growth are suitable temperature and humidity. The presence of moisture is required for mold growth. This doesn’t necessarily mean the surface should be moist. There is often enough moisture in the air from high humidity levels to sustain mold growth. Typically humidity levels above 70% result in larger outbreaks of mold. Therefore, controlling the humidity is essential in the control of mold growth. By monitoring the humidity levels in your warehouse you can react to humidity levels that could sustain mold growth.

Mold also prefers warmer temperatures. Cold climates, freezers, refrigerators, and cold storage can help to reduce mold growth. Monitoring and control of temperature can also, therefore, be effective in combating Mold.

Minimizing Mold Growth By Monitoring Warehouse Temperature And Humidity

Air conditioning units (ACU) should be sized and set to correct operation mode to minimize humidity levels in your warehouse. The system should be set to auto mode. This means the blower will turn on and off depending on the thermostat. It prevents air from carrying moisture from the evaporator coil back into the building before it has time to evaporate from the coil.

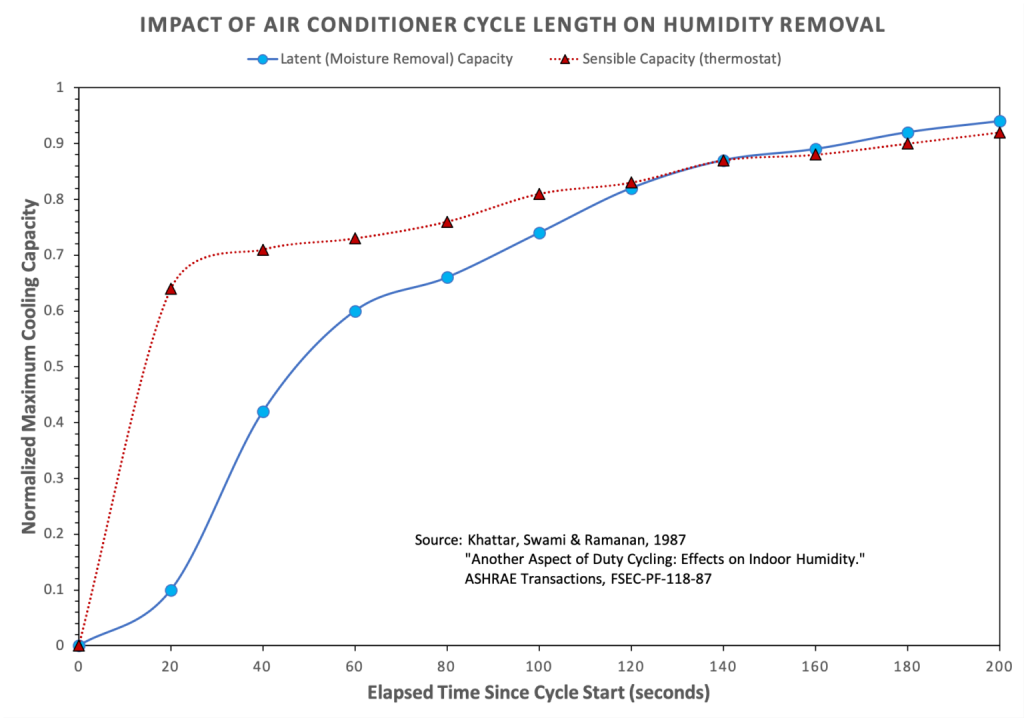

The air conditioning should also be sized correctly. An oversized ACU will be worse than it will be at controlling humidity. It will short cycle, meaning the compressor will not be on for long. The shorter the cooling cycle the less chance the ACU has to remove moisture. The graph below illustrates the ability of an ACU to remove humidity. As you can see, the longer the ACU runs, the more humidity is removed.

Power monitoring sensors can be used to determine if your ACU is short cycling.

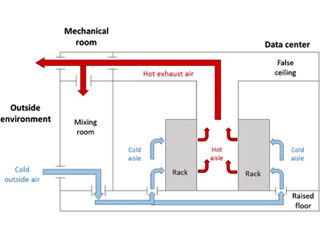

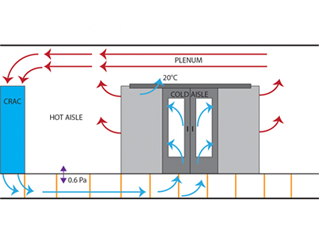

The pressurization of the warehouse space is also important. In a hot and humid climate, the building space should be slightly positively pressurized with respect to the outdoors. If the warehouse is depressurized, then warm and humid air will be drawn inside. Even if doors and windows are closed, there are always pathways for air to enter. If the warehouse has hollow walls of gypsum board, for example, the hot humid air can be drawn through these cavities. The cool surface of the walls results in condensation on the interior cavity of the walls. This can result in significant mold growth in hidden areas of the building. Differential pressure sensors can monitor building pressurization by checking the differential pressure between the inside and outside of the warehouse.

It is therefore important in a warehouse storage facility to monitor the relative humidity (RH%) to ensure that mold growth that can damage boxes and produce is controlled.

Types Of Warehouse Storage

When the quality and purity of the products rely on correct storage it is critical that a warehouse temperature and humidity environmental monitoring system is employed.

- Ambient Temperature- refers to products that can be stored in the warehouses’ natural condition.

- Air-Conditioned Storage- is where products should be stored between 56°F and 75°F. Confectionary is a typical example of this.

- Refrigerated Storage means a required temperature range of 33°F – 55°F.

- Cold Storage requires temperatures of 32°F and below.

The above environmental warehousing conditions can be implemented through different storage methods. Temperature-controlled storage utilizes heating or cooling systems. These maintain the temperature required for the stored products. Climate-controlled storage, often used interchangeably with temperature-controlled, includes dehumidifiers or humidifiers. Not only is temperature-controlled but so is the humidity.

Warehouses that provide temperature or climate-controlled storage will have an annual audit. This temperature mapping allows systems to be adjusted to maintain the required environmental conditions. This is a reactive measure.

A proactive measure would be a permanent monitoring system, that includes data logging, reporting, and alerts. Sometimes a wall-mounted LCD display is incorporated. Real-time monitoring and alerts when temperature or humidity is outside of the required parameters can save thousands of dollars in lost stock.

Most Effective Way to Supervise Warehouse Humidity and Temperature?

A warehouse temperature monitoring system ensures that the appropriate temperature, humidity, and other elements are always within the required thresholds to keep stored commodities in good condition.

Warehouse managers may now devote more attention and resources to the day-to-day management of warehouses thanks to a professional, round-the-clock temperature-monitoring system.

Warehouse Temperature Monitoring Systems

Wireless Temperature and Humidity

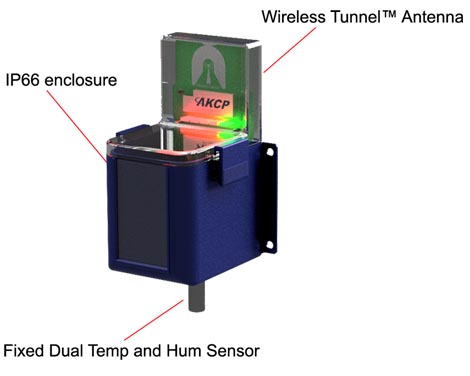

A wireless monitoring system is the best choice for you if you require a cost-effective solution that is simple to install and maintain while yet providing accurate temperature and humidity monitoring. It’s a cost-effective and dependable way to track temperature and humidity inside your warehouses without compromising your stored items. A base station and wireless sensors that can monitor the parameters are frequently included. The devices are simple to set up and save electricity. These batteries can last up to ten years without needing to be replaced.

As a result, if you require dependable, automatic temperature and humidity level monitoring as well as timely warnings for suitable and immediate remedial actions, you should purchase a wireless warehouse monitoring system right now.

Wireless sensor monitoring systems are easy to install in a warehouse environment. Typical problems usually include power for the sensors and restrictions on running cables due to snagging on forklifts. AKCP provides a Wireless Tunnel™ LoRa-based wireless warehouse temperature and humidity monitoring system. Easily deployed, with 10-year battery life. Centralized monitoring and alerts with AKCPro Server.

What Damage Can Be Caused?

What Damage Can Be Caused?