The separation of cold supply air from hot exhaust air is known as data center containment. Containment allows for a consistent supply temperature to IT equipment’s intake and warmer air to be fed back into the cooling infrastructure. However, there are some myths surrounding data center containment that we will address in this article.

Benefits Of Data Center Containment

-

Reduced Energy Consumption

-

Increased Cooling Capacity

-

Stable Supply Temperature For IT Equipment

-

More Cooling Capacity Available For Additional IT Equipment

-

Increased Uptime

-

Extended Lifecycle Of IT Assets

The above is all true, but let’s take a look at some of the myths surrounding data center containment. But first, what is hot and cold aisle containment?

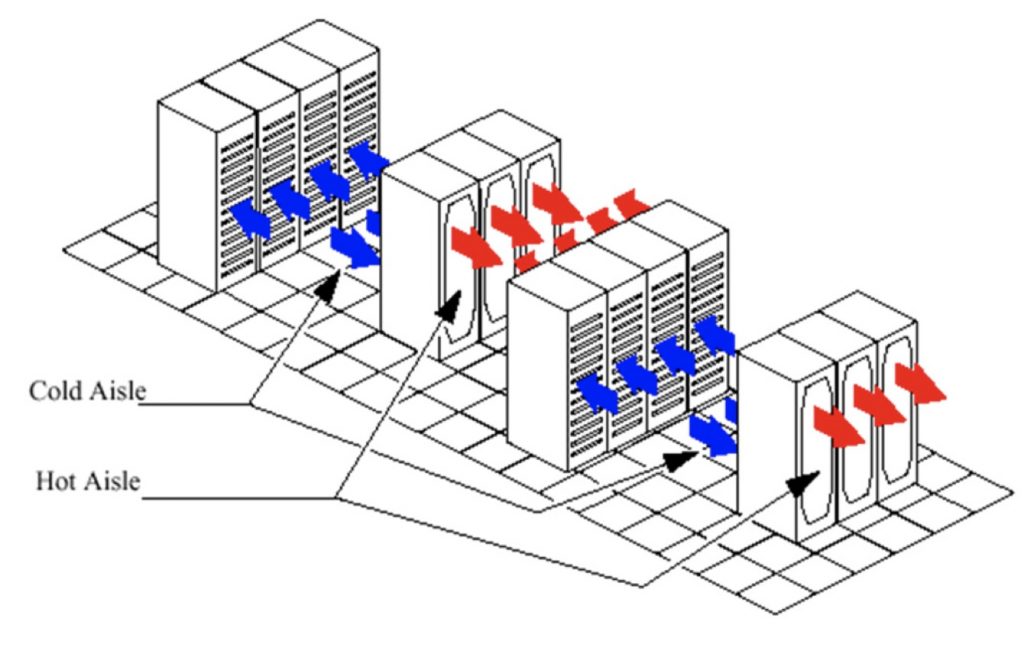

Hot Aisle And Cold Aisle Containment

The Following Are Some Of The Benefits Of Hot Aisle Containment:

- Improved energy efficiency, with energy savings of 40% or more when compared to an uncontained environment.

- The data center’s open sections are cool, and they can be used for low-density racks or storage cabinets.

- For technicians and engineers, the uncontained area provides a more comfortable working environment.

- Because hot air is correctly recovered, accurate supply air distribution is less important.

- It is possible to avoid the use of costly raised floor distribution systems and supply ducts.

The Following Are Some Of The Benefits Of Cold Aisle Containment:

- Easy to implement without the need for additional fabrication to contain and return exhaust air such as a drop ceiling or air plenum.

- Typically less expensive to install than hot aisle containment.

- Easier to retrofit in existing data centers.

- Doesn’t need to be on a raised floor, though it often is.

Containment’s acceptance as airflow management (AFM) technology has been influenced by a number of factors. The following are some of the key drivers:

- The requirement to lower operating expenses by improving the efficiency of the cooling infrastructure.

- The necessity to reduce the temperature of IT equipment’s intake air.

- The need to increase the utilization of computer room space.

According to recent research by the Uptime Institute, 78% of big data center operators have already used containment. However, there are still a few common myths and half-truths concerning the benefits of containment.

Myths Of Containment In Data Center

1. Eliminates Bypass Airflow

-

The total amount of air produced by the cooling units is decreasing.

-

IT equipment necessitates a greater volume of air.

2. Containment ALONE Can Reduce Operating Costs

3. Perforated-Tile Placement Doesn’t Matter Anymore

Photo Credit: www.accessfloorsystems.com

4. Containment Increases The Return Air Temperature To Cooling Units

5. Containment Curtains Are Unnecessary

Photo Credit: cool-shield.com

Data Center Containment and DCIM Software

-

Maintain proper inlet temperatures in all of your containment aisle’s server racks.

-

Increase temperature setpoints securely to save energy and promote green efforts.

-

Increase uptime by receiving real-time alerts when preset thresholds are exceeded.

-

Trend active power, energy costs, and environmental conditions quickly and easily.

-

Other facility equipment, such as CRACs, building meters, PDUs, and UPSs, should be monitored.

-

Produce energy cost reports for billing purposes.

AKCP Air Flow Monitoring Solutions

A data center’s reliability and safety come from a sound monitoring solution. As a vital part of data center management, monitoring should enable comprehensive tracking of environmental parameters in an IT environment.

The Cabinet Analysis Sensor (CAS) features a cabinet thermal map for detecting hot spots and a differential pressure sensor for analysis of airflow. Monitor up to 16 cabinets from a single IP address with the sensorProbeX+ base units.

Differential Temperature (△T)

AKCP CABINET ANALYSIS SENSOR

Two strings of 3x Temp and 1x Hum sensors make up the cabinet thermal maps. Keep an eye on the temperature in the front and back of the cabinet, as well as the top, middle, and bottom. In AKCPro Server cabinet rack map views, the△T value, or front to back temperature differential, is generated and shown with animated arrows.

Differential Pressure (△D)

To prevent air from mingling from the hot and cold aisles, there should always be positive pressure at the entrance of the cabinet. Because air goes from high to low-pressure zones, it’s critical to ensure that the front of the cabinet has higher pressure and the back has lower pressure for efficient cooling.

Rack Maps and Containment Views

Dedicated rack maps displaying data gathered by Cabinet Analysis Sensor can be configured with an L-DCIM or PC with AKCPro Server installed to give a visual depiction of each rack in your data center. Containment views can be set to display a sectional view of your racks and containment aisles if you’re operating a hot/cold aisle containment.