If data center managers can forecast the future they can reduce downtime, wasted energy, and data center design problems as a result. Accurate future forecasts are no longer unattainable with today’s technology. Using CFD Modeling data centers analysis you can model airflow simulations and predict temperatures in various spots data centers.

CFD Modeling data centers help you examine possibilities, consider the causes and effects of hotspots in data centers, and make decisions through simulations before making physical changes in your data center. CFD simulations can help run your data center more efficiently and safely. CFD modeling has been used in a variety of disciplines throughout the years, including biomedical, aerospace, film graphics, and game development. CFD modeling has progressed to the point where it can now be used as a viable design and maintenance tool for data centers. With extensive 2D and 3D CFD analysis, predictive modeling, what-if scenarios, and capacity planning may be done.

This software may be depended on for information such as the state of your present data center and projections of what might happen in the future. As a result, the data center may be constructed in advance, long before the equipment is deployed, so that it can be controlled based on individual demands and features.

Technicians at data centers can see and give electricity and cooling. Meanwhile, IT planners can put in place IT systems in areas where electricity and cooling are accessible.

By incorporating the CFD model into the data center process, users will be able to:

- Streamline capital expenditure expenses and increase data center design effectiveness.

- Predict each IT device’s thermal and electrical resistance.

- Carry out failure scenarios to guarantee that the system’s resilience can be maintained.

- Examine the many vendor choices.

- Hotspots can be predicted, planned for, identified, and avoided.

- Increasing the amount of capacity that may be used without diminishing the amount of active time

- Thermal solutions are being tested.

Here are a few instances of what strong CFD modeling software can accomplish.

- Make A Better Cooling Decision

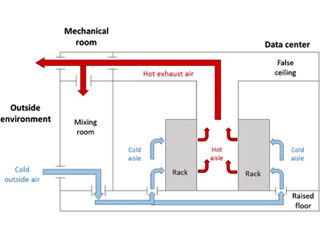

How do you know which air conditioning system is ideal for your space? You may use CFD modeling to assess alternative techniques in terms of availability, capacity, and efficiency without having to relocate equipment or devices. You can do the following using this software:

- Examine how effective cooling shelves and aisles are.

- Look for regions that get more chilly air than they need.

- The equipment site does not receive enough airflow to identify possible hotspots.

- Cooling efficacy is reduced in the right region where cold air combines with heated air.

- The airflow model is located beneath the elevated floor.

- The impact of a CRAC failure on airflow temperatures and the intake rack is depicted.

- Thermal Management Engineering raises the energy efficiency of a building.

- Create a Failure Case Simulation

Do you want to know what happens if you modify the configuration of your data center or replace one piece of equipment with another? You may perform a thorough failure case simulation using CFD modeling tools. Simulate modifications and examine how failure affects the data center environment in terms of availability, capacity, and efficiency if the system fails.

You may also weigh the pros and downsides of various vendor equipment in your data center. If you’re trying to choose between three heat-retaining systems, for example, run them all through CFD modeling to see how they affect your data center.

- Managing Proactive Growth of IT

Data centers require extra devices and equipment in addition to company expansion and data management. IT equipment has evolved over time, and the influence on airflow has shifted as well. This implies that new equipment may or may not match the device’s original position and arrangement.

The capacity of the data center and the risk of downtime might influence the design and interaction of these components. There is no scarcity of airflow once a succession of new pieces of equipment has been acquired and installed. It will be ineffectual and inefficient in this manner. You may determine the optimal design configuration before placing the device and equipment by modeling a change plan first. See firsthand how the data center airflow and temperature distribution are affected by the equipment layout, the position of the refrigeration unit, the hot and cold retaining aisles, under-floor barriers, and various vendor equipment.

CFD Modeling Data Centers Cut Costs and Boost Uptime

Photo Credit: blog.e-i-eng.com

When it comes to data center operations, system administrators frequently put uptime first. On the other side, business line executives take uptime for granted and are more concerned with operational costs. Datacenter infrastructure management (DCIM) software is one technology that meets both of these objectives, and it has grown in recent years to become a vital component of both uptime and cost control.

The market for data center infrastructure management solutions will reach $7.5 billion by 2020, according to the Uptime Institute. Why is there so much expansion? Newer management technologies are meant to detect and fix problems with as little human participation as possible. DCIM technologies today, through modeling and prediction, may proactively notify IT management systems of anticipated physical infrastructure problems and how they can affect specific IT loads by linking power, cooling, and space resources to individual servers. This real-time understanding of continually changing power and cooling capacity is critical for safe server placement in virtualized and dynamic cloud systems.

The impact of a new physical server on power and cooling distribution may be predicted using modern planning techniques. The impact of relocation and modifications on data center space, as well as power and cooling capacity, is calculated using planning software tools.

These smarter technologies also allow IT to warn lines of business about the repercussions of their actions before making server provisioning choices. Carbon footprint and the carbon tax will be affected by business actions that result in greater energy use in data centers, for example. With these new capabilities, it is also feasible to a chargeback for energy consumption, which can change the way decisions are made by connecting energy usage with business goals.

AKCP Central Monitoring Software

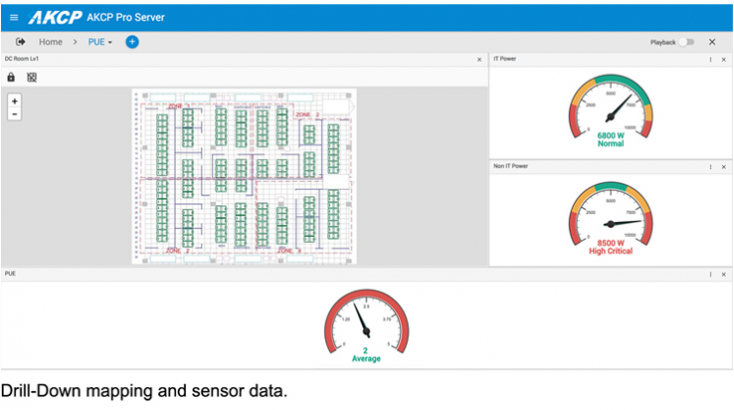

AKCP Pro Server is a world-class software for Data Center Infrastructure Management (DCIM). Avoid the complexity and cost of many popular DCIM software. AKCP Pro Server distills the essence of what DCIM should be to a simple, easy-to-use application. Configure dashboards to display the data you need, with drill-down mapping taking you from a data center-wide to a cabinet-level view. A dedicated rack map shows smart rack sensors such as thermal maps and RFID Swing Handle lock information in a graphical display. Example of cabinet rack view with cabinet thermal map sensors in AKCP Pro Server

Custom Desktops, Graphing, And Drill Down Mapping

AKCPro Server has a variety of ways to display and monitor the data from your deployed sensors. Desktops are customizable, with different users able to save their own configuration. Add graphs, maps, rack maps, video feeds, sensor status, and logs to your desktops. Choose from a selection of gauges to display sensor data.

Reference Links:

https://ieeexplore.ieee.org/stamp/stamp.jsp?arnumber=7279063

https://it-resource.schneider-electric.com/software-digital-services/new-data-center-prediction-and-simulation-tools-cut-costs-and-boost-uptime

https://www.coolsimsoftware.com/Webinar-Archives/Data-Center-Energy-Reduction/Simulating-Data-Center-Energy-Linking-CFD-and-Cooling-Plant-Modeling