Each of the racks in the AKCP test data center will be equipped with 3x 9kW space heaters to simulate servers. This allows us to operate at 27kW per rack. With the initial setup of 8 racks we will have a total heat capacity of 216kW. With relays to automate turning on and off the space heaters and changing fan speeds we can simulate the reality of a dynamic data center with heat loss that increase and decrease, and fan speeds changing. With he use of our differential air pressure sensors we will be able to control the speed of the in row AHU fans to match the air demands of the racks.

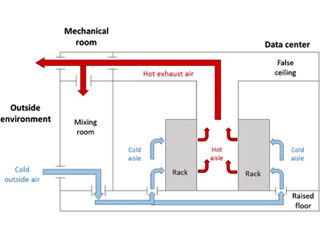

It is important to maintain a balanced air pressure between the hot aisle and the cold room of the data center. When the racks are operating at maximum capacity they will be sucking more air. We must balance the supply air from the AHU’s to match the air demands of the racks. By monitoring differential air pressure we can speed up or slow down the AHU fans to maintain a very slight positive pressure in the data center room. This ensures the racks have sufficient air and we do not have a build up of high pressure on either side of the rack.

Failure to match the demands can lead to either a high pressure zone inside the hot aisle or in the cold room. Pushing more air than is necessary from the AHU results in a build up of high pressure in the data center. This results in wasted cooling energy, and forcing more cold air through the racks than is needed. A low ∆T on the racks and a high ∆P would indicate this problem.

Vice Versa, if the AHU is not pushing enough air, the racks will be sucking through air quicker than it is being replaced. This results in a build up of pressure in the hot aisle. A high ∆T across the rack is likely to occur as heat builds up in the hot aisle, and rack inlet temperatures are also likely to increase. There is the potential for recirculating hot air as it tries to escape back into the cold room.