Proper cooling in a data center environment has always been a critical system component. All computer systems generate heat during operation, and this heat must be removed for the systems to function properly. In this post we will be examining ways of optimizing data center cooling.

Data Center Cooling

The cooling solution in a traditional data center environment is a computer room air conditioner (CRAC) or computer room air handler (CRAH), these units are used to cool the entire facility. The chilled air could either be pumped into the room through ducts, or may be distributed via a raised floor system. However, this cooling method does not take into account the location, the density, or the distribution of power among the various IT workloads. Therefore, these CRAC/CRAH cooling systems are generally highly inefficient and can lead to “hot spots” in the data center layout that can harm heat-sensitive equipment.

To combat the “hot spots” and prevent unplanned downtime and decreased performance due to unmanaged heat, data center operators often have to overprovision the cooling capacity. However, this just wastes massive amounts of energy without actually solving the problem.

Cooling Optimizations

Due to advancements in IT and increased density of components, data center heat loads continue to increase. Data center operators need to adopt new strategies for keeping the IT environment cool, while keeping the energy costs in check. Implementing optimization techniques such as in-row and adiabatic cooling, coupled with aisle containment, can dramatically reduce the cooling costs and lessen the risk of “hot spots” in data centers of all sizes.

It is usually easier to implement cooling optimization systems than one might think:

- They can be usually deployed with a very low capital cost that is accessible to just about any budget

- They can be deployed in small increments and scaled

- They can yield savings in the range of 5-25% of the annual cooling budget

- They do not require intervention with the cooling control system

- They allow real-time visibility to the effects of changes made

- They can have ROIs as short as a few months

- They are often complemented by utility rebates

Adiabatic cooling is a new liquid cooling technology, and is part of the “free cooling” techniques. Adiabatic means the process of reducing temperature through a change in air pressure caused by volume expansion. The incoming warm and dry air is forced through a wet filter, which reduces the air’s temperature as it goes through the filter. This improves cooling efficiency, since the temperature of the air taken in by the cooling unit is already pre-lowered.

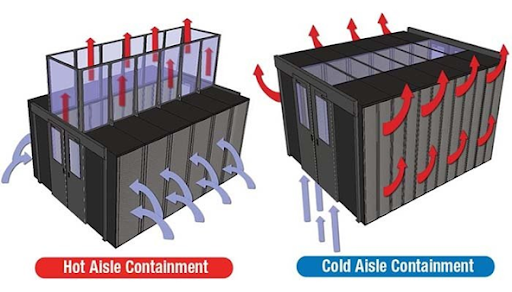

Aisle containment aims to optimize the flow of cooling air.The server racks will be arranged into hot- and cold-aisles; the front of the racks will draw in the cool air (cold aisle) and expel their heat through the rear of the cabinets into the hot aisle. This is an effort to separate the cool and hot air, and avoid mixing them. This can provide significant energy savings (up to 40%).

In addition to implementing physical appliances, data center infrastructure management (DCIM) systems can give operators the ability to further optimize cooling efficiency by analyzing heat loads and temperature readings.

Optimization Techniques

There are three main strategies that can be used to achieve better cooling for data centers:

1) Eliminating hot spots

Hot spots in a data center are not caused by inadequate cooling capacity, but rather by problems with the cooling’s airflow — the chilled air is not reaching, or not evenly reaching the IT equipment. Data center operators can resolve airflow issues by bringing the cooling systems and the airflow closer to the heat load, and ensuring that the chilled air does not mix with the hot exhaust air of the IT equipment.

In-row cooling

The in-row cooling units are placed directly inside a row of IT racks and cabinets. These cooling units could be suspended from the ceiling, placed on top of a cabinet, or be mounted on the floor. The best in-row cooling systems are the ones which are housed in enclosures with similar dimensions to a data center cabinet, therefore seamlessly integrating with the existing layout. In-row cooling systems will create a shorter airflow path than with traditional CRAC/CRAH units, so the chilled air will reach the IT equipment more quickly – it’s so efficient that almost all of the cooling capacity can be used to dissipate heat.

Aisle containment

Combining the in-row cooling solutions with aisle containment can further increase the cooling efficiency. As we described above, the aisle containment systems are designed to prevent the mixing of the chilled intake air with the IT equipment’s hot exhaust air. In traditional data centers often the hot aisle containment is used, in which the racks and cabinets are arranged with the server exhausts facing each other. Then the hot exhaust air is isolated and will be sent directly to the CRAC unit. In-row cooling is often used in conjunction with the cold aisle containment. The cold aisle is enclosed and separated from the rest of the room to create a closed-loop arrangement that focuses the chilled air on the equipment.

2) The advantages of evaporation

Most of the data center cooling units are Direct Expansion (DX) air conditioning systems, which are using some kind of refrigerant to directly cool the incoming air intake of the unit. However, as technology evolves and data center power densities continue to increase (for example using GPU-accelerated systems for data analytics and other compute-intensive workloads), many operators are switching to water cooling solutions to more efficiently cool the IT equipment.

Water is a very efficient medium for cooling: it has about four times the thermal capacity of air. In a usual data center’s cooling system, water is chilled to about 15°C or 59°F using a Direct Expansion unit, then pumped to a CRAH. The CRAH will draw in warm air through the chilled water coils, and into the IT environment. The heat will be dissipated by pumping the water back through the chiller.

Adiabatic cooling

The newer adiabatic cooling systems – which are based upon the cooling properties of evaporation – can be even more efficient, require less maintenance and use less water than traditional chilled water systems. As we described above, in adiabatic cooling the ambient air is passed through a wet filter that further cools the air. Then this air can enter the cooling system at a lower temperature, increasing efficiency.

3) Measure and manage temperatures

Choosing the optimal cooling system for any given data center will depend upon its size, the geographic location, the type of IT equipment used, and the power density. In a data center, the cooling requirements and heat zones will change continually as the IT equipment is added or replaced, and racks and cabinets are moved around.

Installing an environmental monitoring system is considered to be a hefty part of the annual improvement budget. However, advances in wireless monitoring technology now allow a detailed environmental monitoring solution to be implemented for a fraction of the cost of the wired solutions – as low as $3,000 – $5,000 for a mid-sized data center.

DCIM systems

All data centers have a need to manage their heat loads. To help optimize the cooling in the data center, DCIM systems can be used. These software solutions can perform a wide range of functions, including real-time monitoring of the energy consumption of IT equipment and the infrastructure components (PUE). This will help to achieve a more efficient cooling of the equipment, while keeping the energy costs lower.

A DCIM software will be able to show the temperature data in dashboards and other visualization tools, to help data center operators better understand the power consumption and identify hot spots. Some of the available DCIM systems support integrating external cooling management systems or are using their own cooling management modules, which make it easier to correlate the energy and cooling data.

How can AKCP help?

DCIM

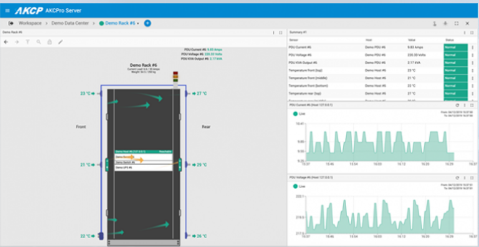

To help optimize your data center’s cooling, AKCP has a DCIM solution available: AKCPro Server. AKCPro Server integrates all your environmental, security, power, access control and video in a single, easy to use software.

Environmental Monitoring

Monitor all your temperature, humidityy, airflow, water leak and other environmental sensors. Configure rack maps to show the thermal properties of your computer cabinet, check the temperature at the top, middle, bottom, front and rear, as well as temperature differentials.

Security Monitoring

Ensure that your facilities and critical infrastructure are secured. Door contact sensors, audible and visual alarms are configured and managed from your custom desktops in APS.

Power Monitoring

Monitor single-phase, three-phase, generators and UPS battery backup power. AKCP Pro Server performs live Power Usage effectiveness (PUE) calculations so you have a complete overview of your power train and how adjustments in your data center directly impact your PUE.

Access Control

AKCPro Server is used to administer the access rights and schedules for all AKCP Door Controll, Cabinet Control and RFID Cabinet locks. Secure your assets, control access and generate reports to give a complete audited trail of access.

Video Monitoring

Video feeds from Integrated ONVIF compatible IP cameras and cameras connected to AKCP securityProbe base units can be monitored and recorded in AKCPro Server. Synchronize sensor events with video in the playback window for an “eyes on” to any sensor events.

Sensors

For monitoring data center temperatures, AKCP has multiple sensors available in wired or wireless form. In addition to the Airflow Sensor which can detect the presence or absence of the air flow, you can use our Cabinet Analysis Sensors to help you get a visual representation of each rack in your data center, the temperatures, differential pressures and the flow of air.

Airflow and Thermal Mapping for IT Cabinets

The Cabinet Analysis Sensor (CAS) features a cabinet thermal map for detecting hot spots and a differential pressure sensor for analysis of the air flow. You can monitor up to 16 cabinets from a single IP address with the sensorProbeX+ base units. A Wireless Cabinet Analysis Sensor is also available using our Wireless Tunnel™ Technology (see details below).

Differential Temperature (△T) and Thermal Maps

The cabinet thermal maps consist of 2 strings of 3x Temperature and 1x Humidity sensor. With these sensors you can monitor the temperature at the front and rear of the cabinet, top, middle and bottom. The △T value, front to rear temperature differential is calculated and displayed with animated arrows in AKCPro Server cabinet rack map views.

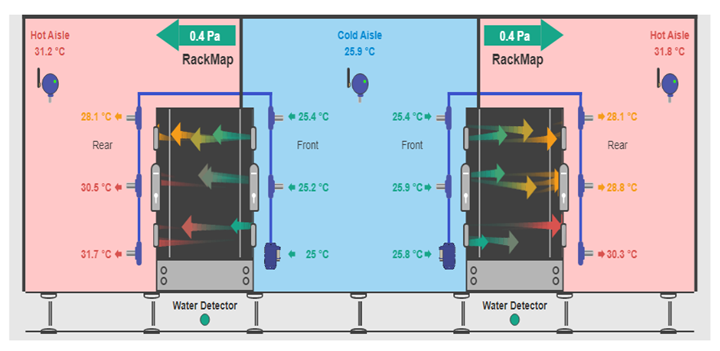

Differential Pressure (△D)

There should always be a positive pressure at the front of the cabinet, to ensure that air from hot and cold aisles are not mixing. As the air travels from areas of high pressure to low pressure, it is imperative for efficient cooling to check that there is higher pressure at the front of the cabinet and lower pressure at the rear.

Rack Maps and Containment Views

With AKCPro Server installed, dedicated rack maps displaying Cabinet Analysis Sensor data can be configured to give you a visual representation of each rack in your data center. If you are running a hot/cold aisle containment, then containment views can also be configured to give a sectional view of your racks and containment aisles.

Wireless Cabinet Analysis Sensor – All In One Wireless Cabinet Sensor

The Wireless Cabinet Analysis Sensor (W-CAS) has the same features as the wired Cabinet Analysis Sensor (CAS): cabinet thermal map for detecting hot spots, differential pressure sensor for analysis of airflow and 2x dry contact inputs for door security sensors. Powered by USB, or 4x AA rechargeable batteries and using AKCP Wireless Wall Penetrating Technology, the data is collected and sent to one of our wireless sensor gateways.

Door Contacts

I/O dry contact inputs can be used to monitor the front and rear doors of the cabinet, or alternatively alarm outputs from a UPS or other rack mounted equipment.

Conclusion

The need for managing the IT heat loads is just as old as the computing technology itself. In the recent years, more tools became available to data center operators to effectively cool and manage their equipment, while reining in the energy costs. For all operators who are looking to optimize their data centers, it would be a wise recommendation to investigate into the aisle containment, in-row and adiabatic cooling technologies, and into DCIM systems. As a result of optimization, it is not uncommon to see 5-25% annual cooling cost savings. If simpler, passive solutions are chosen that don’t interface with controls, the ROI can be in as little as a few months.