Introduction

An essential part of data center management is knowing where a cable goes, why it is there, and what it connects to. Labeling terminations and cable runs plays a crucial role in the efficient operation and maintenance of a data center.

Cable Schedule Design and Cable Identification Tips

Before installing a single cable, a plan of the cable runs, lengths and terminations should be created. This serves as the installation guide and as a record, of when, by whom, and what was installed. It may also include other pertinent details such as the type of termination or cable specifications.

The plan may be drawn in CAD software, or within your Data Center Infrastructure management (DCIM) software itself. AKCPro Server DCIM includes network and powertrain mapping which can be used for creating such a plan. Creation within your DCIM has the added benefit that the drawing becomes a part of your “digital twin”. It serves as a reference to the real world installation, and can be integrated with analytics such as identifying routing issues and testing alternative pathways for connections.

However these are topics for another article. Here we will focus on the standards related to the labeling of the cables during installation.

The first step is to establish your unique identifier (ID). This can be composed of numbers, letters, or a combination of both, as long as it maintains clarity and functionality. Here are some practical suggestions:

- Logical Naming Scheme: Ensure that the numbering and naming scheme adheres to a logical hierarchy. This approach makes it understandable to others who work on the network at a later date.

- Consistency: Maintain consistency between the information in the drawings and implementation.

- Machine-Readable Labels: Printed labels rather than hand written are preferred due to their ease of readability. Use a simple font to maximize clarity.

These basic guidelines help establish a useful cable identification system that aids efficient installation, maintenance, and troubleshooting.

Standards for Labeling Cables

Due to the importance of the labeling of cables within the network there have been industry standards developed.

ANSI/TIA-606-C

ANSI/TIA-606-C cable labeling standard is a voluntary standard for cabling infrastructure. It was developed by the Telecommunications Industry Association (TIA) and was first published in 1994 under ANSI/TIA-606-A followed by 606-B. The standard has been updated several times since then, with the most recent revision being published in 2017.

Key Requirements of ANSI/TIA-606-C

ANSI/TIA-606-C specifies the following key requirements:

- Labeling: All cables should be labeled with a unique identifier. The below describes how to label in accordance with the 606-C standard.

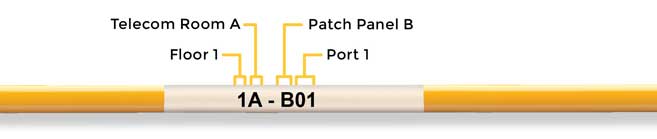

Original Link Cable Identifier

Link identifier not terminated in the same space

Link identifier terminated in the same space

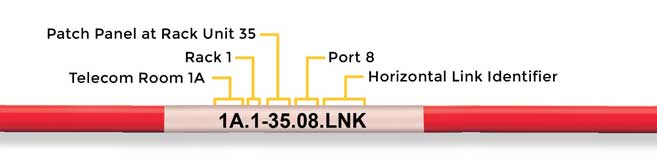

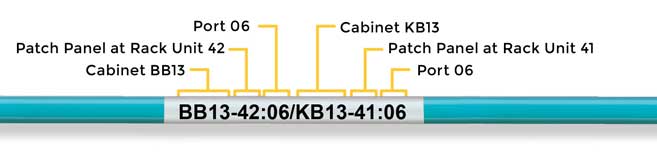

Patch panel identifier example

- Documentation: A record of all cables should be maintained. This record should include the cable identifier, source and destination of the cable, cable type, and cable length.

- Management: Cables should be managed and routed to prevent damage and ensure that they are properly installed and maintained. This would include the use of structured cabling in the data center.

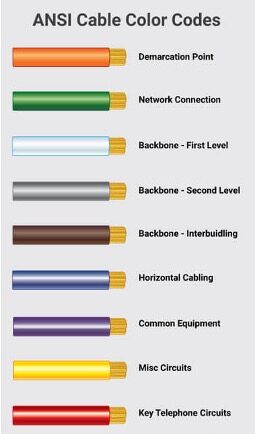

- Color Coding: The ANSI/TIA-606-B standard recommends the following color coding scheme for cables.

ISO/IEC 11801

ISO/IEC 11801 is an international standard for the design and installation of telecommunication cabling. It was developed by the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) and was first published in 1995. The standard has been updated several times since then, with the most recent revision being published in 2017.

Key Requirements of ISO/IEC 11801

ISO/IEC 11801 includes a number of key requirements, including:

- Cable selection: The selection of cables should be based on the application, the environment, and the performance requirements.

- Connector selection: The selection of connectors should be based on the cable type and the performance requirements.

- Pathway installation: Cables should be installed in pathways that are designed to protect them from damage.

- Maintenance: Cables should be maintained on a regular basis to ensure that they are in good condition.

Benefits of Confirming to a Cabling Standard

Both the above standards are valid guidelines. It will be up to the individual data center operator to select which works best for them. The key benefits of either however are the same:

- Reduced downtime: Proper planning and labeling of cable infrastructure helps reduce downtime, making it easier to troubleshoot cable related problems.

- Improved efficiency: Labeling makes it easier to find and identify cables.

Labeling Considerations

Here are some essentials when it comes to labeling your cables.

- All cables should be labeled on both ends.

- The labels should be permanent and easy to read.

- The labels should include the following information:

- Cable ID

- Source and destination of the cable

- Cable type (e.g., Cat5e, fiber optic)

- Cable length

- Durable, the labels must hold their position and remain readable.

- Permanent printing, ensure the ink will not rub off or smear.

- Placement of the label where it can be easily identified.

- Color coding of labels with cables to identify cable types and use.

Labeling Methods

There are several different methods for labeling data center cables. The most common methods include:

Cable tags. This is the most common method of labeling cables. Cable tags are small, plastic tags that can be attached to the cable with a self-adhesive backing.

Heat shrink labels. Made of a material that shrinks when heated. Sometimes a clear heat shrink may be placed over a sticky label to protect it and prevent it coming off.

Direct-on-wire labels. Applied directly to the cable without the need for a tag or sleeve. This is a good option for labeling cables that are in tight spaces.

Labeling Tools

There are several different tools that can be used to label data center cables. The most common tools include:

- Label printers are used to print labels on demand. This is a good option for organizations that need to label a large number of cables. They can be printed in advance, and distributed to installation technicians with the drawings.

- Label applicators are used to apply labels to cables. This is a good option for organizations that need to label cables quickly and easily while “on the job”.

Companies who specialize in printing and labeling technologies have solutions suitable for meeting the needs of network labeling, together with software to create the labels. Most of these software solutions are capable of taking in an Excel file or CSV file and populating the labels automatically. This saves time and ensures synchronization between the information contained in drawings and the labels implemented during installation. One of the leading suppliers of labeling solutions for the data center are Brady, who provide a complete solution of labeling software, hardware and consumables.

Conclusion

Proper labeling of data center cables is essential for efficient and reliable data center operation. By following the standards and guidelines outlined in this article, and employing tools such as AKCPro Server Network Mapping, organizations can ensure that their data center cables are labeled properly.