What is Data Center Energy Modeling

Energy modeling is the process of forecasting how much energy a system will consume and simulating the change when certain parameters are adjusted. Energy modeling is a useful tool for data centers as it assists in analyzing how to lower energy consumption making the facility more efficient.

Why Model?

Photo Credit: www.decision-making-solutions.com

The main rationale for modeling data center energy use is enabling the examination of “what if” scenarios that would otherwise have to be tested experimentally. In general, such experimental verification is costly and risks data center downtime. Modeling, on the other hand, is less costly and risk free for the infrastructure.

Another important use of energy modeling is to provide a baseline, or “beginning point,” for energy efficiency initiatives. Historical energy usage information can be utilized to build this baseline for an existing data center that has been in operation for two or more years. However, because historical data for a new “greenfield” data center is not available, a building simulation model of the facility can be used to establish a baseline. The models can accurately predict energy use patterns hour-by-hour for a year of operation. This data can be used to analyze the new data center design energy efficiency before any construction begins. It provides “before-the-fact” confirmation of energy-saving improvements in the design. The results are compared to alternative energy saving tactics. Such proof is often required to justify the capital investment needed, especially on large-scale initiatives.

Equipment to Model

Chillers and HVAC systems fluctuate in energy consumption depending on the loads being placed on the data center infrastructure. Some of the variables that effect their energy use are :-

- Supply Water

- Supply Air Temperature

- Internal Latent Loads

- External Effects (Dry-Bulb or Wet-Bulb Temperature)

When major pieces of equipment are replaced, it may be necessary to model the changes beforehand. After installation it is worth recording the energy use over the course of several months to compare consumption before and after the change validating any energy cost reductions that the model predicted.

Required Data For Energy Modeling

Successful energy modeling requires accurate data input. When determining what data is necessary for an accurate energy model, keep the following in mind:

-

Proper Degree Of Detail: Data collecting levels and scope will differ from one company to the next. Some may opt to collect data on particular processes via sub-meters, while others may merely meter the whole facility.

-

Account For All Energy Sources: Keep a cost-based inventory of all energy purchased and generated on-site.

-

Document All-Energy Usage: Gather energy bills, meter readings, and other usage statistics for the sources listed above.

-

Collect Data On A Monthly Basis for at least two years, or more frequently if feasible. Use the most up-to-date information accessible.

-

Collect Non-Energy-Related Data For All Facilities And Operations: To be able to normalize and benchmark, non-energy-related data for all facilities and operations, such as building size, building construction, site orientation to the sun, shading, operating hours, and so on, may be required.

Model Normalization

Unless the data is normalized, models or actual test results can produce unexpected or inaccurate results. Typically, the site will wish to normalize for occupancy and kind of occupancy, such as servers versus storage versus network, bandwidth consumed, real data throughput, weather, major construction changes, and so on.

For example, if the temperature was substantially hotter one year than the next, annual energy demand for an existing air conditioning system may be significantly greater one year than the next. If the data is not standardized for weather, comparing the energy use of an old air conditioning system during one year to the energy use of a newly installed efficient air conditioning system during the following hotter year might suggest that the energy use did not vary at all. To satisfy the larger cooling load and reject heat under more demanding ambient circumstances, the new system had to work longer and harder.

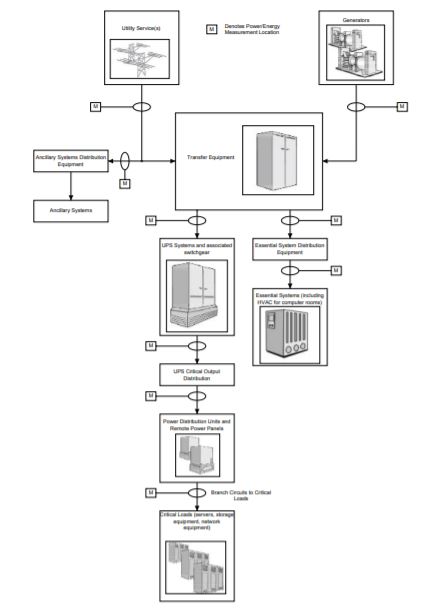

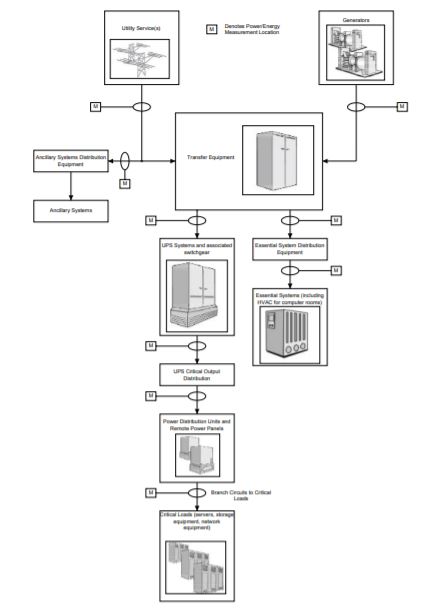

What Do I Measure, And Where Do I Measure It?

Photo Credit: stockphoto.com

The decision of which quantities to measure and data to use as the input has a significant impact on the software selected. After all, the analytic software’s outputs are only as good as the data provided. At each point of interest,

current,

voltage, and

power/energy measurements are unquestionably required. Where such measurements should be used is partly determined by the metrics’ definitions. More complex features, like status inputs and waveform captures, can be specified to add more functionality.

Permanent VS. Temporary Monitoring Solutions

Photo Credit: www.missioncriticalmagazine.com

The decision to utilize temporary or permanent monitoring solutions is influenced by a number of factors, including cost, space availability, system size, and whether or not some monitoring capacity already exists in the infrastructure.

For limited-scope

energy management studies, temporary monitoring in the form of portable data recording test equipment can be utilized in small-scale systems. This is beneficial for analyzing such systems over short time periods, such as a few weeks to a few months, and capturing data fluctuations owing to time, weather, and occupancy or production. The findings may be extended over time to calculate yearly energy use and expenses.

Monitoring equipment that is permanently placed can likewise be utilized for the following purposes, eliminating the requirement for invasive temporary installation. It is also feasible to offer real-time energy information if such equipment is connected to the data center’s communications network. A system like this could already be in existence at a data center, but it’s not being exploited to its full potential.

Power monitoring equipment that is permanently installed and connected to the facility’s communication network is nearly always necessary for a large-scale system. Not only should the specs for such hardware be based on energy management requirements, but also on the necessity for power quality and event recording data. In a single device,

high-end power monitoring devices can offer all of the essential monitoring capabilities for a specific system location. The ability of the monitoring equipment to interface with the “software monitoring and analysis layer” is one specification that is always required for energy management reasons.

The Software Monitoring And Analysis Layer

The analysis of energy use data is just as vital as collecting it, and all of the time, effort, and money spent building the hardware monitoring layer are aimed at making that data available for analysis. The most effective way to do this analysis is through software, which is why it’s called the software monitoring and analysis layer. Such software includes

real-time and long-term analytic components, as well as a database that records critical system data. Once the required data is available and important analysis instructions are coded, a well-designed software solution should be able to complete energy analysis duties automatically, presenting the analysis in a report format that may be adjusted based on its intended audience.

Real-Time Monitoring and Analysis

Key performance data is monitored real-time analysis and may often be shown in any way the user desires. Energy data real-time analysis runs in parallel with power quality data analysis, such as a sequence-of-event recording system, and may or may not be part of the same software platform.

Real-time monitoring and analysis are crucial tools for detecting large changes in energy use. It assists in the equipment energy use patterns and the identification of equipment and systems that operate outside of these regular energy usage patterns. When a piece of equipment, system, or subsystem exceeds its usual energy use pattern, action can be taken to perform planned maintenance in a timely manner to maintain the data center running at maximum efficiency. Real-time monitoring and analysis are also critical for real-time energy regulation.

Energy monitoring and management software can begin collecting data during the early stages of a new data center’s operation to assess the facility’s and many of its sub-systems’ true energy usage trends. Data purification algorithms can automatically correct metered energy data and fill in gaps in missing data.

When attempting to compare real-time values of the energy measurements to their respective established standards, caution should be exercised. The findings will be meaningless unless the benchmark in question was explicitly designed for usage in real-time. This is because the energy spent accumulates over time, and it is this accumulation of energy over time when managed within the facility’s strategic performance targets, that results in the energy savings intended.

AKCP Power Monitoring

AKCP Cabinet Analysis Sensor

AKCPro Server is an ideal DCIM solution. Perfect for those people who don’t have the budget or need for complex DCIM software, but require a capable monitoring system for their data center. With many advanced features such as Cabinet Thermal Mapping, Drill Down Mapping, Graphing, VPN connections to remote sites, AKCPro Server is the ideal choice. AKCPro Server is capable of live PUE calculations, so you can see real-time the effect changes you make have on the PUE.

By utilizing the AKCPro Server live PUE calculations you can see the immediate effect that changing the power usage has. Shut down fans and cooling systems and see how it improves the PUE. At the same time, use thermal rack maps to ensure that you are not overheating any servers. Adjusting the thermostat on the CRAC units will undoubtedly result in improved PUE, but what about its knock-on effect on the lifespan of servers?

By employing the complete AKCP ecosystem of products, Thermal Map Sensors, AKCPro Server and Power Meters work together to give a complete analysis and assistance in cutting power costs and improving PUE.

Reference Links:

https://www.missioncriticalmagazine.com/ext/resources/

https://www.timesnews.net/news/local-news/article_165d9ff6-5d23-11ec-b4bd-ff4cdd1e457b.html

https://www.environmentalleader.com/2021/11/energy-efficient-data-center-market-seeing-significant-growth/