Medical Refrigerators are used to store temperature-sensitive drugs and vaccines. Many vaccines require storage between 2°C and 8°C. Time spent outside of this temperature range are known as temperature excursions. Vaccines and drugs have something known as a drug stability budget, which is the total amount of time the substance can be kept outside of its recommended storage range.

It is important therefore that the environmental conditions inside your medical refrigerator are monitored to ensure temperature excursions are monitored. It is a legal and regulatory requirement in many countries to monitor the storage temperature of temperature-sensitive drugs. Failure to do so can ultimately result in decreased efficacy of the vaccine or drugs being administered.

Medical refrigerators should be monitored for their temperature in accordance with recommended guidelines for temperature monitoring of medical refrigerators. Vaccines and drugs should be stocked in accordance with industry best practices.

It will be noted that the temperature probe should be installed in a glass or plastic vial that contains a liquid buffer. Typically Glycol is used to suspend the temperature probe. This liquid dampens the response of the sensor, Moree closely simulating the temperature change experienced by the vaccine or drugs inside the refrigerator.

When the door of the refrigerator is opened, or the compressor is running, there are temperature fluctuations inside the chiller compartment. These fluctuations are temporary in nature, for example, once the door is closed the temperature will quickly return to its required range. The air temperature changes are not reflected as quickly in the liquid. Therefore, to avoid false positives, unnecessary alerts that temperature is outside of range, the glycol buffer is used.

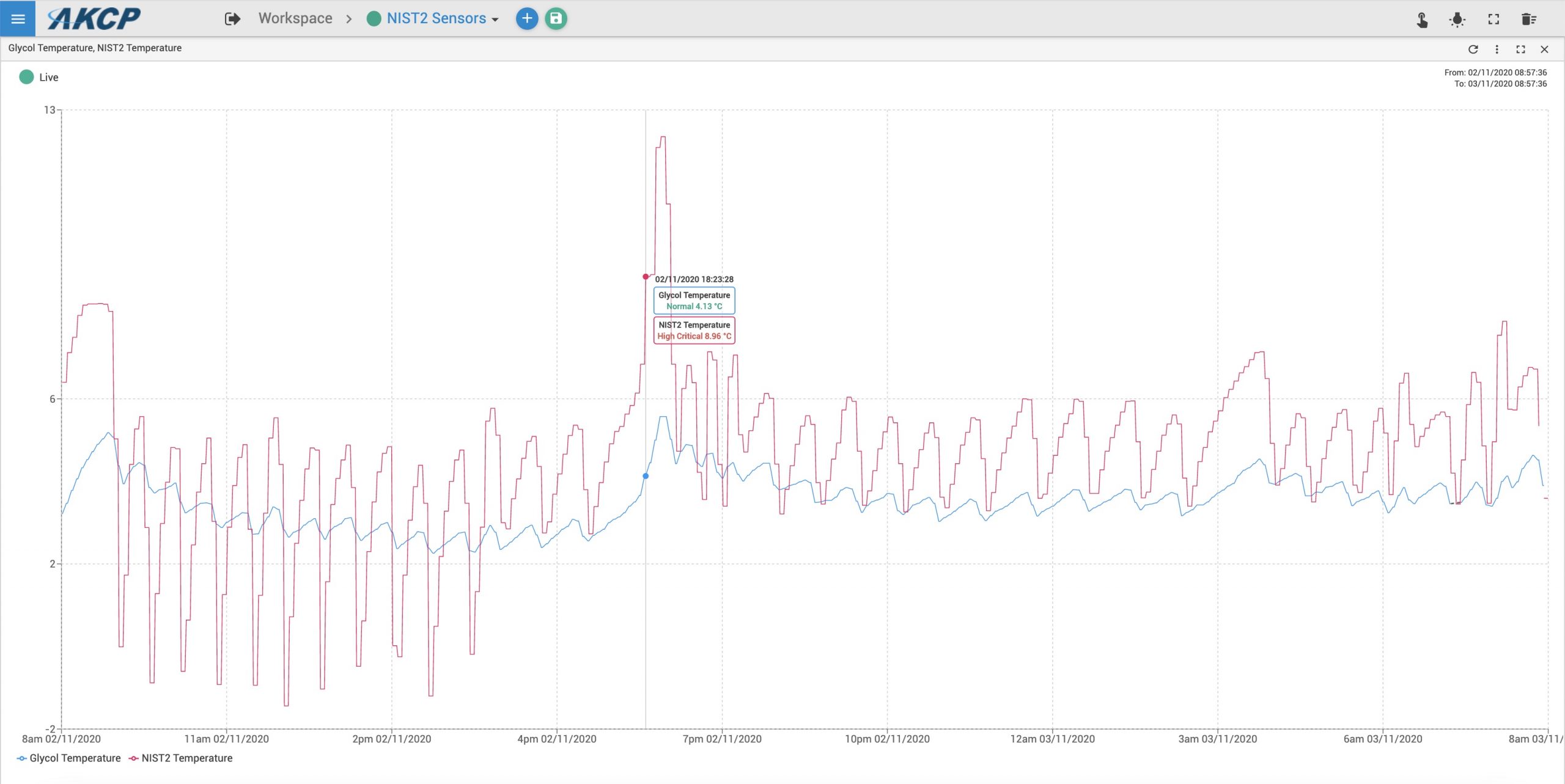

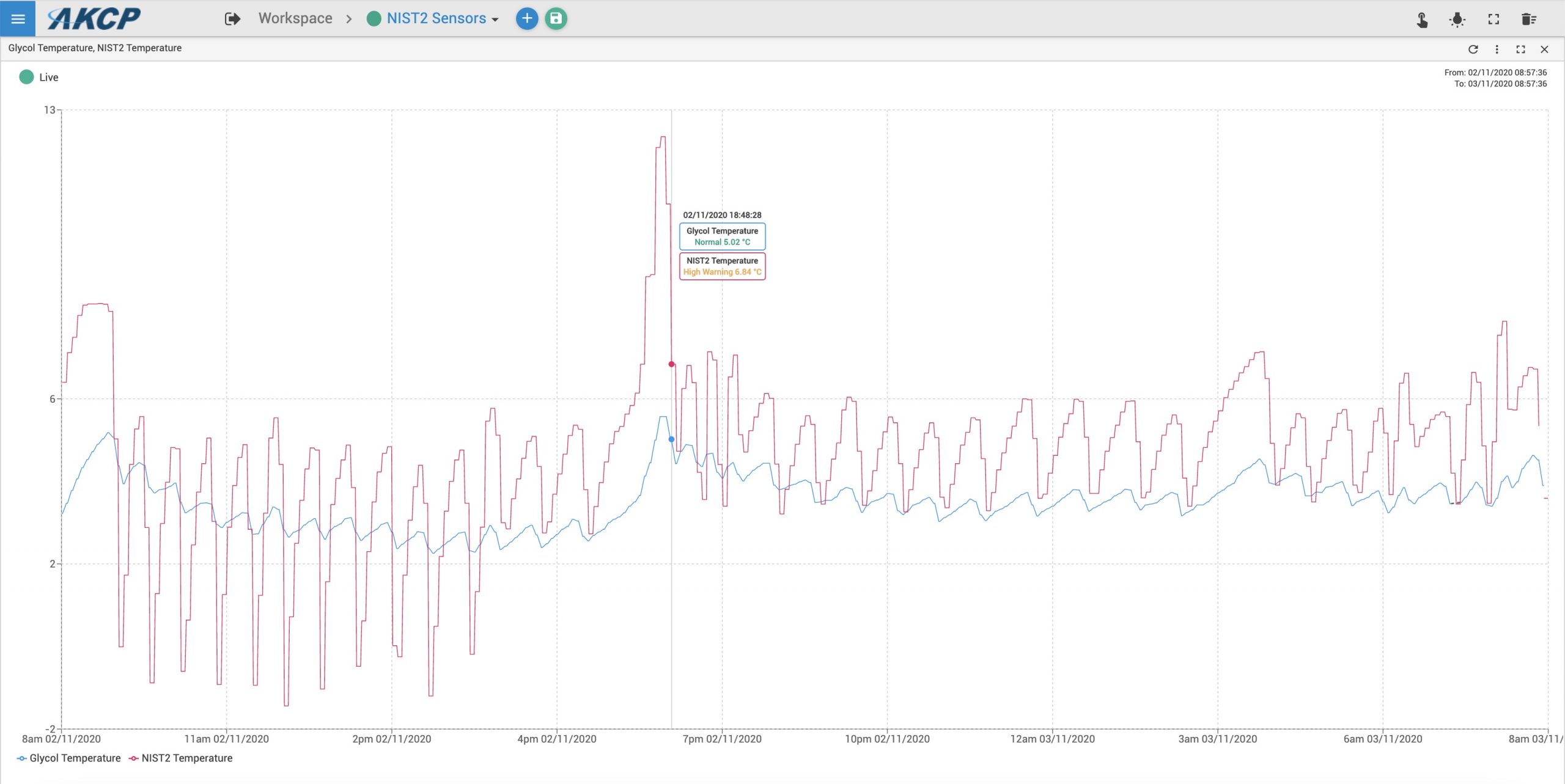

The below graph shows clearly the rapid response to air temperature changes compared to the dampened response to temperature changes of the sensor suspended in glycol.

The red line, is the air temperature inside the refrigerator, the blue line is the temperature of the glycol. The compressor cycles can clearly be seen, with rapid fluctuations in temperature, and a wider temperature range reported. It can also be seen that at 18:23:28 hrs the air temperature was reporting a high critical status above 8°C, where as the glycol temperature sensor is still within normal range at 4.13°C.

The high critical status changed to high warning at 18:48:28 hrs, meaning that without the glycol a temperature excursion of over 20 minute would be recorded, counting against the drug stability budget of the pharmaceutical products. This would unnecessarily count against the efficacy of the drugs, potentially resulting in disposal of the products and the following of temperature excursion procedures. The Glycol temperature sensor shows that the temperature did not exceed 5.57°C, and therefore was well with the 2°C to 8°C range.

AKCP provides easy to install, wireless temperature sensors for medical refrigerators, together with attachment to a jar of glycol. The temperature sensors feature our NIST2 and NIST4 technology, with calibration integrity check (NIST2) and failover (NIST4). Sensors are NIST traceable calibrated. NIST2 sensors include 2 calibrated temperature sensors that are checked once a second. The value of the two sensors is compared and if it is found to be outside of the accuracy range an alert is generated that the sensor is out of calibration. With the NIST4 sensor when an out of calibration status is detected a second pair of sensors takeover for continual monitoring and seamless graphing of the temperature inside your medical refrigerator.