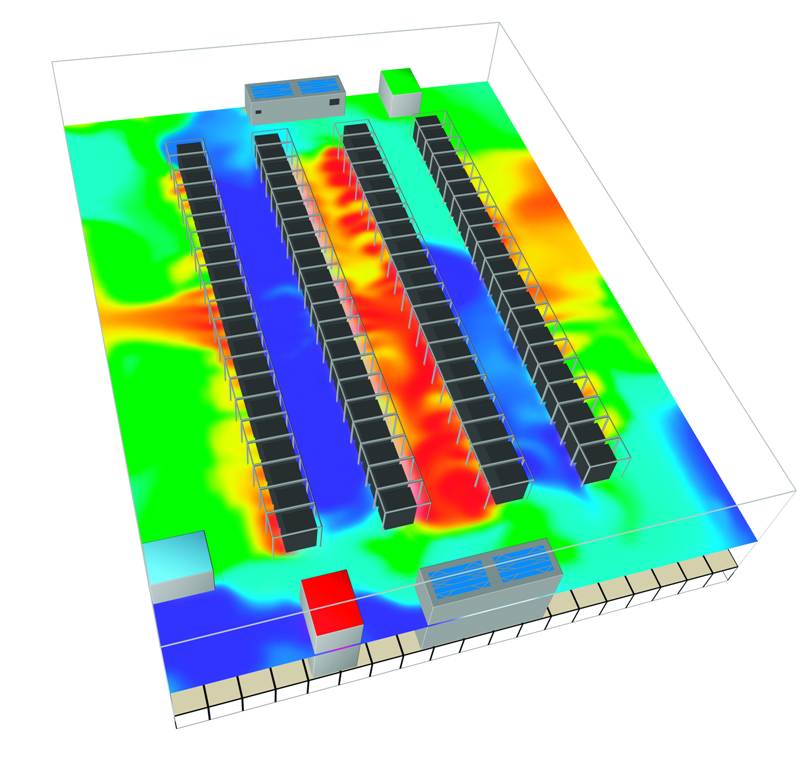

A temperature sensor is among other sensors used in monitoring environmental elements in data centers like temperature, power, and airflow. These sensors allow data center managers to monitor and immediately address the issues that may arise. Which is made possible by wired or wireless temperature sensors. These sensors can be integrated with data center storage, servers, and large network equipment products.

Monitoring these environmental elements through sensors on server racks enables data center managers to maintain the necessary airflow, IT load, and cooling adjustments as needed. These sensors are configured to send alerts should the safe operating temperature be exceeded.

Some Data center infrastructure management (DCIM) systems have remote monitoring and management features for cooling units. As a response to unstable heat loads, these systems can automatically make cooling adjustments. This will not only prolong the life of IT equipment but will also reduce data center cooling costs.

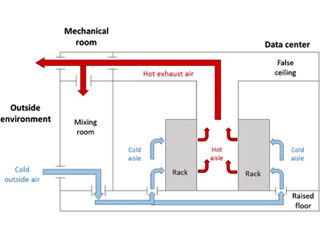

The present practice of data center management of thermal conditions with regard to pressure differential is inefficient. This practice was brought about by the early days of data centers that had raised floors and tile selection depending on the perforation percentage to manage the airflow in racks.

This thermal management is still being implemented in raised floor and non-raised floor data centers. However, it usually drives the fan speeds too high. Furthermore, it also does not allow the management of temperature-related service level agreements (SLAs).

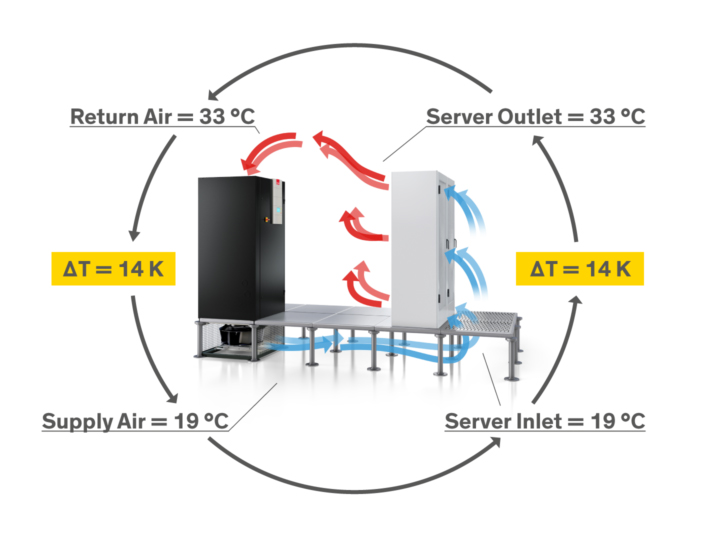

Delta T

Photo Credit: www.stulz.de

To optimize cooling center efficiency, another route is to manage the delta (∆) T. This is the temperature differential between the cool air going into the data center and the warm air going back to the cooling units. Through this, the fan speeds in data centers are minimized as opposed to the delta (∆) P approach. It also allows for the continuous management of thermal efficiencies with respect to the intended design of the system.

Placing temperature sensors in front of equipment racks allows for visibility into rack-level temperatures that can be used simultaneously with the ∆ T measurement to comply with the temperature SLAs. Depending on the rack temperature needs, the delta T is adjusted. This is recognized by the control system, which then generates alerts.

Since the delta T control strategy is becoming more prominent and there is a need to manage SLAs, temperature sensors are becoming pivotal for a more efficient data center management, monitoring, and control. The sensors that are situated play a significant role in their value and subsequent return on investment (ROI).

When a temperature sensor is placed accurately, the building provides a more comfortable experience. Inadequate placement of sensors can cause the HVAC equipment to function improperly, which can lead to energy waste, equipment wear and tear, and comfort issues.

Temperature Sensor Placements

Some bad locations for temperature sensors are as follows:

- Above or at the back of equipment that expels hot or cold air

- In exterior doors that are usually opened

- Under direct sunlight

- On the ceiling

- Below ceiling fans

- Near cooling and heating supply ducts

- Under supply duct

- In the return ductwork

Temperature sensors placed too close to supply ducts will result in extreme fluctuations of room temperature readings as the cooling and heating equipment goes on and off.

When the hole in the wall for the wires of the temperature sensor is not properly sealed, air will escape through the wall and blow the back of the temperature sensors. Which will tamper with the readings and produce inaccurate results. For exterior walls, this issue may be worse since the air passing through might be affected by sunlight or the air temperature outside.

Correct Temperature Sensor Placements

To produce accurate temperature room reports, temperature sensors must be placed around five feet high on an interior wall or column in a central location with good circulation. It is also important to ensure that there is no hot or cold equipment near the vicinity.

One technique would be to see if each sensor could be found in a minute to check proper sensor placement. If they could be found within a minute, then they are in a good location. Since there is much equipment added to rooms over time, it is important to check if the sensors are still adequately placed periodically. Remote access to heating and cooling equipment data as well as the thermostat will allow staff to check if the sensors are properly placed.

Ensure that the Foundation Has Intelligent Controls

Suppose temperature sensors will be used as part of a control strategy. In that case, it is vital for the thermal management control system to have the necessary functionality and intelligence for its execution. There is a need for unit-level controls that are capable of automating the usual routines of the cooling system. There should also be a supervisory control system that has the ability to manage data center conditions.

Place Wireless Temperature Sensor for Added Flexibility

The usual homes and offices typically employ the exhaustive use of wireless technologies through voice recognition systems and smart thermostats. To maximize the use of this technology, it would be best to apply them to data centers as well.

Wireless sensors are easier and cheaper to place. Therefore, being the more flexible choice as opposed to wired sensors. They can be of particular use to data centers that are not yet at full capacity. When using wireless sensors, new sensors can be added along with equipment racks. Wireless sensors also allow for the sensor networks to immediately adapt to layout changes without rewiring.

In checking wireless sensors, it is best to give attention to sensor functionality, battery capabilities, and security.

Wireless Thermal Mapping of IT Cabinets

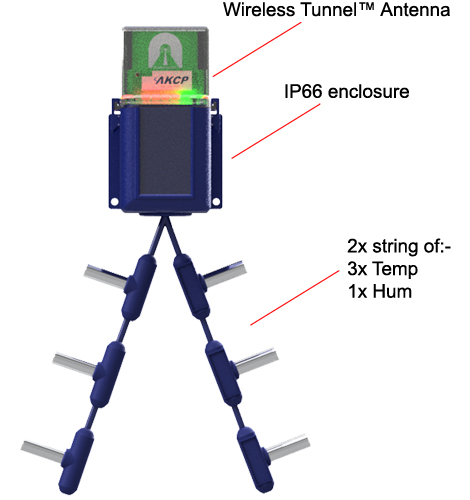

Wireless Cabinet Thermal Analysis Sensor

Wireless thermal mapping of your IT cabinets. With 3x Temperature sensors at the front and 3x at the rear, it monitors airflow intake and exhaust temperatures, as well as provides the temperature differential between the front and rear of the cabinet (ΔT) Wireless Thermal maps work with all Wireless Tunnel™ Gateways.

Thermal Maps are integrated with AKCPro Server DCIM software in our cabinet rack map view. For more details on the cabinet, thermal map sensors view here.

Simplify Deployment

The layers between the management system and sensor data should be eliminated. Through this, deployment is simplified, and costs are reduced. Usually, data gathered from sensors are transferred from the cooling unit to the monitoring card in monitoring systems. They are then transferred to the network switch, building management systems, and monitoring systems. It is best to link these sensors to a gateway that connects directly to the supervisory control system. In effect, multiple layers of integration are eliminated. Since a single software system will be used for all installations, installing sensors across multiple sites removes local variations regarding data integration with the building management system.

Conclusion

It is best to strategize where sensors will be placed to employ a control strategy effectively. America Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) guidelines suggest placing sensors in every third rack with three measure points included in each rack. However, this may not be applicable for all control applications. It is then important to choose the right sensor provider with data center expertise to best configure the network relevant to the organization while generating the needed amount of data at the lowest possible cost. AKCP has more than thirty years of experience in professional sensor solutions and networked temperature, environmental, and power monitoring in the data center.

To properly manage temperature SLAs, conditions must be measured at the rack. Using wireless humidity and temperature sensors with an integrated supervisory control system allows for a better transition to the delta T approach, which has proven to be more efficient than the delta P control strategy while ensuring proper temperature control at the racks.

Reference Links:

https://powerhousedynamics.com/blog/thermostat-temperature-sensors-wrong-place/

https://www.datacenterdynamics.com/en/opinions/three-tips-using-temperature-sensors-improve-cooling-system-efficiency-and-sla-management/

https://www.energystar.gov/products/use_sensors_and_controls_match_cooling_and_airflow_it_loads