The amount of stored data worldwide rocketed to 44 zettabytes in 2020, making it more challenging for data center managers to extract, monitor, and understand information. This escalation has created an increased demand for a more comprehensive data analysis for easier monitoring. In a data center, one of the parameters that are being monitored is the temperature in the facility and within racks and servers. Thus the emergence of many service providers that offer monitoring solutions and temperature sensors.

In many years, monitoring evolved from manually logging temperature to digital and smart systems. Today, a new method of temperature monitoring management is developed. Temperature data visualization is now used for a faster representation of data. This system uses graphs and lines that are easier to comprehend. These provide users with tools to extract meaning from data with less significant limitations.

Data Center Temperature Management

The data center runs with its core components – power, compute, and cooling. All equipment runs off a reliable power source, so it is the holy grail of the data center. The computers are as important as they do the work in processing the data. Lastly, cooling maintains the temperature threshold within the facility. In an average data center, about 40% of the total power consumption is allocated to cooling systems. It is affected by the hardware, thus developing an efficient tool to track the temperature is vital.

The use of more powerful servers and a more efficient storage solution are recommended. This is to respond to the constant increase of data. However, this becomes more challenging considering the cost of maintaining cooling systems. The investment in operating the server-associated cooling system is the same as purchasing the server.

Overall, the impact of the temperature is not only limited to the performance of the data center. It also falls back to profitability- which is the main goal of a business.

DCIM vs. DCHM

Temperature is being managed by exploring the facility. Administrators study its layout and airflow. Racks are also arranged following the hot aisle and cold aisle method introduced by IBM. Additionally, managers can also rely on management software to improve their cooling systems. This software extract data to better understand the temperature condition of the data center.

There are two types of data center management software: DCIM and DCHM. Each type has its focus. Yet, both are equally significant in managing data center temperature.

It is defined as a tool designed to measure the changes in temperature within the facility. This software provides information primarily about the changes in ambient temperature. It is currently used by data centers that have monitoring through temperature sensors. The sensors give an alert in the event of temperature fluctuation. This ensures that the power, cooling, and physical security necessary are in the best condition to keep the systems up. But, it does not specify the triggering factors of this change and the exact location where it has happened.

It is important to take note that equipment temperature differs from rack to rack or component inside. One of your locations on the rack contains different types of devices and servers. DCHM can project the differences in temperature level in this equipment and focus on the energy consumption and utilization of IT equipment.

Data generated by the DCIM about the temperature of a specific device can be connected to the information derived from the DCHM. In this way, managers can find the correlation between the two variables. This leads to correct conclusions and sound decision-making.

Temperature Visualization

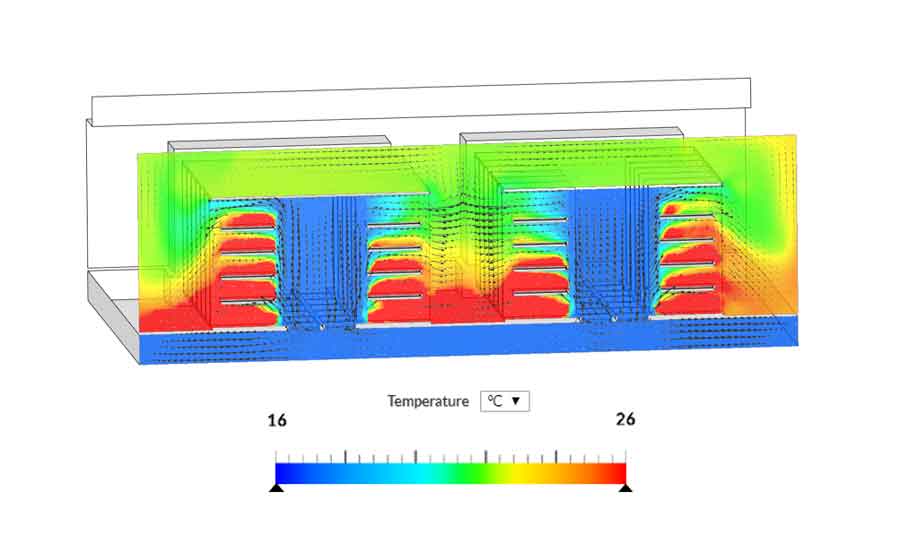

Photo Credit: www.missioncriticalmagazine.com

Data visualization provides an explicit idea about the meaning of the information. Using graphs and figures makes data more natural for the human mind to comprehend. This provides an easier way of identifying trends, patterns, and outliners even with large data sets. Did you know that 90% of data in the world has been generated for the past two years? Furthermore, 2.5 Billion GB of new data is predicted to be generated every day.

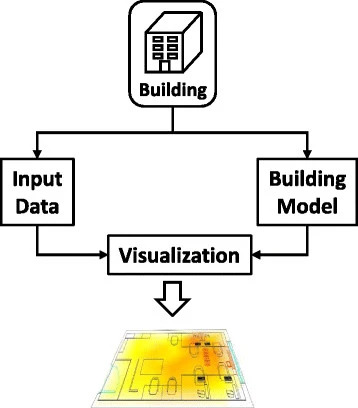

The entire process of visualizing acquired temperature data can cleave up into three parts. These are Input Data Part, Building Part Model, Visualization Part.

Photo Credit: media.springernature.com

- Input Data Part – collection and selection of raw data from the sensors to generate input data

- Building Part Model – 2D floor plan or 3D building model is loaded, which becomes the background for visualization. Also, it includes all the factors that influence the temperature within the data center.

- Visualization Part – Transforming the numeric data into visual information

Effective temperature visualization is a fundamental part of running a data center. It helps the manager to avoid incorrect analysis of data and come to grips with the temperature condition. Temperature data can often be connected to a physical location. It can also have abstract temporal data that shows temperature changes at a given time. For every 30 seconds, one device can measure up to 2,880 single temperatures in a day. For a data center room containing 100 racks, this means 288,000 data points a day. Can you imagine those having more than hundreds of racks? Couple this with the data coming from the different server rooms that are all being processed concomitantly. This has been a challenge for data centers as multifarious temperature data sets cause limitations for data visualization.

Visualization Methods Using Temperature Sensors

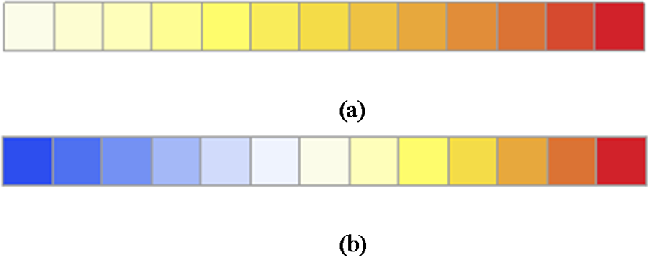

There are a variety of methods used in the visualization of temperatures. The most commonly used is colors. Colors are generally used in temperature visualizations to describe hot and cold values. Having that said, the use of color visualization should be carefully considered. A confusion may happen for colors have no significant meaning. do not mean additional insight. Color hue is recommended for categorical data. Categorical data contains one or more categories without intrinsic ordering. For ordinal data, color intensity is suitable. This data follows a strict and clear ordering of categories. As for the color, a warm red color depicts high temperature while blue is for cold low temperatures.

Aside from colors, some use lines, text, and graphs. Other temperature visualization methods are:

- A Scatter plot is a type of data visualization that shows the correlation between two different variables. The data is shown by plotting different data points between the x and y-axis. The dependent variable, such as time, is usually presented on the x-axis. The dependent variable is on the y-axis. There is no connection between the points so they look “scattered”. This look gives this type of data visualization its name. It often provides information about the trends instead of temperature changes between specific data points.

- A line diagram is a type of visualization used to represent the value of temperature over time. Just like the scatter plot, the line diagram is also consisting of the x and y-axis. However, data points are plotted and connected by a line into a “dot-to-dot” approach.

- Table lens is another type of temperature visualization method which dynamically explores a large amount of turbulent data. It reduces the required amount of display space by shrinking the height of the table rows. Columns accommodate variables while the rows represent data items. Bars with different lengths communicate data value by clicking on the row. This can be suitable to the data center by representing the temperature of each rack on a single row and details of the devices placed on the rack.

- Clustered heat maps can be also used in temperature monitoring where rack temperature is presented as a timeline. It consists of a rectangular tiling, with each tile shaded on a color scale. They represent the value of the corresponding element of the data matrix. Yet, this method can also show a confusing collection of data leading to failure to understand the large data sets.

Photo Credit: www.researchgate.net

Temperature Sensors for Visualization

Temperature Visualization is an integral part of today’s data center monitoring. However, with the amount of temperature data that is being generated every minute inside data centers, comprehensive visualization is a challenge. Data are time-consuming and hard to understand as they are, so translating them to an easier visualization helps save time and maintain efficient monitoring.

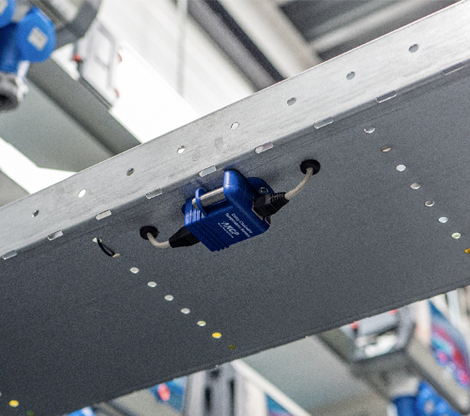

Temperature sensors are vital for temperature visualization. The data presented are collected primarily by the sensors installed within the facility. Thus, behind a reliable temperature visualization is a reliable temperature sensor.

Visualization with AKCP Temperature Sensors

AKCP offers a variety of wired and wireless temperature sensors applicable for temperature visualization in data centers.

Single Port Temperature and Humidity Sensor

Single Port Temperature and Humidity Sensor

When you need to know the temperature of a room, enclosure, or cabinet this sensor can be used. Housed in a thermally conductive metal tube it is accurate and quick to react to changes in temperature. The sensor can be easily mounted with screws, adhesive, or optional DIN rail clips making it ideal to scatter around the facility as well. Combining temperature and humidity into one sensor frees up an additional intelligent sensor port on your base unit. Thresholds can be set for low and high warning and critical parameters. The built-in graphing function of the base unit gives you a pattern of temperature or humidity trends over time.

Cabinet Analysis Sensor

The Cabinet Analysis Sensor (CAS) features a cabinet thermal map for detecting hot spots and a differential pressure

sensor for analysis of airflow. Monitor up to 16 cabinets from a single IP address with the sensorProbeX+ base units. The Wireless Cabinet Analysis Sensor is also available using our Wireless Tunnel™ Technology.

The cabinet analysis sensor combines differential pressure and cabinet thermal maps into one smart sensor. Sensors include:

- A string of 6x Temp sensors

- 2x Humidity for cabinet front and rear

Differential pressure sensor, check for proper pressure differential between front and rear. Ideal for hot and cold aisle containment to ensure proper airflow. AKCPro Server Rack Map View Use the CAS with dedicated rack map views on AKCPro Server. A visual representation of your cabinet, with airflow, front and rear temperatures, temperature differentials, and differential pressure.

Reference Links:

https://homebusinessmag.com/blog/technology-blog/top-3-main-components-data-center-important/

http://cumincad.scix.net/data/works/att/caadria2019_365.pdf

http://www.iaarc.org/publications/fulltext/isarc2014_submission_82.pdf

https://visme.co/blog/scatter-plot/

https://hal.inria.fr/hal-00656250/document