Clark Water, a subsidiary of Manila water, selects AKCP to partner in the installation of an upgraded monitoring solution for their remote sites.

Clark, Philippines, a former US Military Base, now an industrial economic zone, is one of the economic hubs of the Philippines. Clark Water is responsible for supplying over 500 businesses with a reliable and constant water supply. With 32pumping sites around the zone, it is a lot to monitor, manage and maintain. Each site is connected via wired, or at remote locations, wireless network, to their central office. Each site is equipped with a generator, UPS, and a SCADA system.

The requirement was to be able to monitor the generators and fuel tank levels at each of these sites, as well as monitoring of third-party devices such as the UPS. One site is equipped with a mini data center for which access control, temperature and UPS monitoring was also required. AKCP base units with a Cellular Data Modem were used, to ensure that communications and alerts can still be made even in the event of a network blackout.

Typical pumping station site, one of 32 around Clark that were installed with AKCP monitoring solutions.

Typical pumping station site, one of 32 around Clark that were installed with AKCP monitoring solutions.

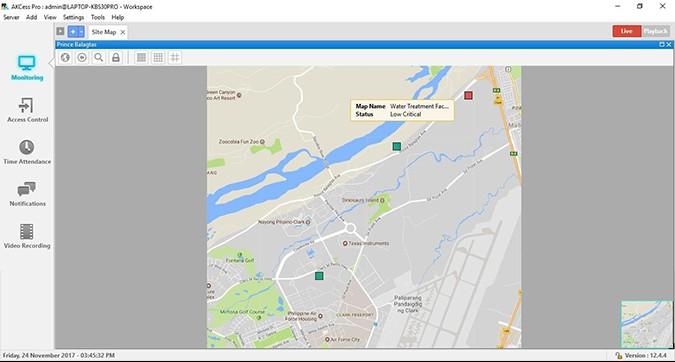

Location of sites referenced in this case study.

Location of sites referenced in this case study.

Central Monitoring Platform

AKCPro Server, AKCP’s central monitoring platform, was installed at the main control room office to provide centralized monitoring and management of all sites. Custom dashboards were set up to display data from the generators and sensors installed at each location throughout Clark. Virtual Sensors were used to monitor the status of UPS backup power systems, as well as the SCADA system for controlling of pumping stations. ONVIF IP cameras were interfaced with AKCPro Server as well as access control for sensitive areas.

With Drill-Down Mapping, AKCPro Server was able to give a visual overview of all sites, and their status at the central control room, making monitoring the situation of each location simple.

AKCPro Server is also used to manage all deployed devices, updating the firmware, configuring the devices, backup and maintenance can all be done through this software.

Drill down mapping of sites in AKCPro Server

Drill down mapping of sites in AKCPro Server

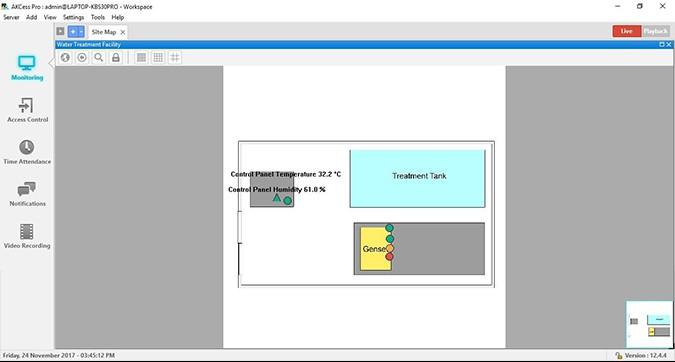

Customized desktops were setup for each site to display the sensors and generator data.

Customized desktops were setup for each site to display the sensors and generator data.

Example of Deep Well site desktop displaying fuel level, battery voltage, temperature and humidity as well as the host status.

Example of Deep Well site desktop displaying fuel level, battery voltage, temperature and humidity as well as the host status.

Deep Well Pumping Station

The deep well pumping station is critical to Clark Waters operations, with the generator running 24 hours per day with a backup secondary genset for emergency use. At this site, the generator did not have a control panel with RS485 Modbus connectivity. AKCP was able to satisfy the monitoring needs by installing our own sensors. An SPX+ with DIN rail mounting was deployed at this site. The SPX+ was equipped with 4 sensor ports and 10 optoisolated dry contacts and cellular data modem for sending SMS in critical situations. A dual temperature and humidity sensor were placed inside the electrical panel.

DIN rail mounted SPX+ installed at the main electrical panel.

DIN rail mounted SPX+ installed at the main electrical panel.

An ultrasonic fuel level sensor provides alerts when the fuel level is critical and requires refiling. Dry contact inputs were utilized to monitor the generator on/off status, as well as provide alerts if the generator doors or control panels are accessed. A DC Voltage sensor was connected to the battery so it’s health can be remotely monitored.

Ultrasonic fuel level sensor and isolated DC Voltmeter installed a generator.

Ultrasonic fuel level sensor and isolated DC Voltmeter installed a generator.

Installing the Ultrasonic fuel level sensor.

Installing the Ultrasonic fuel level sensor.

Water Treatment Facility

Located at the Northern end of Clark, is the main wastewater treatment area. Critical to maintaining a healthy environment it is essential this site is operational 24/7/365.

Clark Water treatment facility.

Clark Water treatment facility.

A larger site than the pumping stations, this was equipped with a larger Cummins genset with ComAp IntelliLite AMF20 control panel. An RS485 Modbus connection was made from the SPX+ to the control panel, enabling AKCP to monitor the engine parameters remotely. Oil pressure, battery voltage, engine temperature, fuel level, engine speed, runtime and engine status, were programmed using the relevant Modbus registers in the SPX+. This allows Clark Water to closely monitor the generator’s status, as well as scheduled preventative maintenance when a specific number of hours runtime is reached for example.

SPX+ with 3G modem and 10x dry contact I/O module installed at generator control panel.

SPX+ with 3G modem and 10x dry contact I/O module installed at generator control panel.

ComAp InteliLite AMF20 control panel provides RS485 connection to the SPX+.

ComAp InteliLite AMF20 control panel provides RS485 connection to the SPX+.

Due to the distance from the main control panel room and the generator, which was located in an outbuilding, the SPX+ was connected via a WiFi network connection, and then to the wired network infrastructure already in place. The cellular data modem provides an extra layer of communications, by sending SMS alerts in critical situations.

Screen capture from SPX+ web interface of generator parameters.

Screen capture from SPX+ web interface of generator parameters.

Mini Data Center

Clark Water’s Lilly Hill location is equipped with a small air-conditioned shelter which functions as a mini data center, managing the communications of the various sites, and giving the main backhaul to the main office.

Operation of this facility is essential for communications from the central office to all pumping stations and water treatment facilities, management and monitoring of the SCADA system, generators and fuel levels.

Genmon installed environmental monitoring devices in the mini data center, using the SP2+ DIN rail mounted in the cabinet with thermal map sensors to monitor the temperature at the top, middle, and bottom of the cabinet. Monitoring of temperature means should the air conditioning fail advance notice is given and corrective action can be taken to prevent overheating of sensitive IT equipment.

RFID Swing Handle Cabinet Locks were added for securing access to the front and rear doors of the cabinet. Centrally managed through AKCPro Server it allowed Clark Water IT staff to control access to the cabinet and provides an audited log of access events.

DIN Rail Mounted SP2+ with internal modem and 3 sensor temperature and humidity thermal map and 2x RFID swing lock handles.

DIN Rail Mounted SP2+ with internal modem and 3 sensor temperature and humidity thermal map and 2x RFID swing lock handles.

RFID Swing Handle Cabinet Locks installed front and rear of the cabinet.

RFID Swing Handle Cabinet Locks installed front and rear of the cabinet.