Prefabricated modular data centers have serviced a wide range of sectors throughout the years. This includes automotive, defense, healthcare, and education. Despite the demonstration of its relevance and importance in today’s society, it’s not the most innovative technology present.

Its rise can be attributed to hyperscalers like Microsoft who have begun to venture into the prefab space. Last 2020, Microsoft introduced Azure Space which they have branded as a portable data center in a box made for specifically tough environments. As seen through industry experience, it is evident that prefab data centers are a proven and tested technology that has been utilized in various sectors for over a decade.

Earlier data center infrastructure management versions had some functionality lapses when it was first launched. And is one of the reasons why prefab data centers have been attracting attention. Its mobility and scalability are factors that drive the market. Clients are able to relocate their data centers instead of destroying them and rebuilding them at the new site. Many organizations consider scalability as one of their biggest challenges. For prefab data centers, the modules can be replaced with ease when there is a need for updated technology or if it becomes obsolete.

Prefab Data Centers for Military Use

Prefab or modular data centers rapidly gained popularity among organizations. It is now being used in various industries and organizations such as in educational establishments, healthcare sectors, life sciences, and government and defense.

The unmatched flexibility of prefab data centers made it suitable for an environment like military camps. Defense department grows more hi-tech, it is essential for armed forces around the world to have reliable data storage and computing power as near the front line as possible.

Prefab data centers can be ruggedized for harsh military environments. Due to this, the military has been using prefab data centers for many years now. Various steps can also be taken to make sure that they are secure and shock-proof. Prefab data centers need to be sensitive compartmented information facility (SCIF) compliant on the frontline so they can prevent electronic surveillance and inhibit sensitive military and security information from leaving. Meanwhile, other manufacturers claim that their units have the ability to withstand small firearms.

Prefabricated Data Centers for Healthcare Centers

Health care is one of the industries that have been using prefab data centers for a long time now. This is more evident in the time of the Covid-19 pandemic. As the pharmaceutical companies were racing to formulate, manufacture and distribute Covid-19 vaccines. Time is limited so vaccine developers cannot wait years for a data center. Thus, the existing prefab data centers were utilized.

Compared to traditional facilities which take 12 to 24 months of construction, prefab data centers only take less than eight months. This quality is essential for situations that call for a fast scale-up.

Hyperscalers also use prefab data centers. Even with their own data warehouses, colocating in facilities with power, cooling, and IT modules. Security concerns that surround these colocation sites must also be considered. The partnership of hyperscaler and datacenter must always remain confidential.

Construction Revolution Through Prefabricated Modular Data Centers

One representative of a prefabricated modular data center is a containerized data center. Deployed by 20’ or 40’ containers that are easily maneuvered. The prefab data center offers fast deployment, expandable, changeable, and movable. With no environmental limitations, deploying at military sites, oceangoing research vessels, ore exploration, and disaster recovery. They are considered a powerful than legacy data centers and the construction costs are less than half.

From the containerized data centers, the modular data centers evolved. For indoor use, even eliminating the container or shelter of the data center while retaining the advantages of the containerized data center.

Containerized data centers are the most usual types of prefabricated modular data centers. The datacenter’s customized infrastructure can also be considered as prefabricated modular data centers.

All In One, No Zoning

Photo Credit: www.pbctoday.co.uk

Prefabricated and Assembly Line Production In-House

Quick and Standardized Installation

Photo Credit: www.vertiv.com

Flexibility

Low Cost and High-Power Density

Full Administrator Control

Wireless Monitoring For Pre-Fabricated Data Centers

Remote Monitoring With AKCP Wireless Monitoring

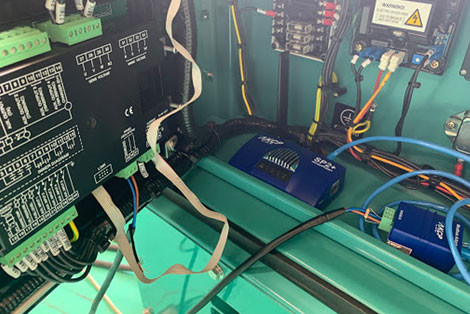

AKCP Wireless monitoring solution enables tracking, alerting, and remote control of your prefab data center infrastructure and energy usage. Thus, you save the operational and staff costs, and you are permanently connected to the systems operating within the IT Container, no matter where it is located.

Datacenter monitoring with thermal map sensors helps identify and eliminate hotspots in your cabinets by identifying areas where temperature differential between front and rear are too high. Thermal maps consist of a string of 6 temperature sensors and an optional 2 humidity sensors. Pre-wired to be easily installed in your cabinet, they are placed at the top, middle, and bottom – front and rear of the cabinet. This configuration of sensors monitors the air intake and exhaust temperatures of your cabinet, as well as the temperature differential from the front to the rear.

- Obstructions within the cabinet

Cabling or other obstructions can impede the flow of air causing high-temperature differentials between the inlet and outlet temperatures. The cabinet analysis sensor with pressure differential can also help analyze airflow issues.

- Server and cooling fan failures

As fans age, or fail, the airflow over the IT equipment will lessen. This leads to higher temperature differentials between the front and rear.

- Insufficient pressure differential to pull air through the cabinet

When there is an insufficient pressure differential between the front and rear of the cabinet, airflow will be less. The less cold air flowing through the cabinet, the higher the temperature differential front to rear will become.

When the data is combined with the power consumption from the in-line power meter you can safely make adjustments in the data center cooling systems, without compromising your equipment, while instantly seeing the changes in your PUE numbers.