Air cooling has dominated the data center cooling industry, not only of its convenience but as previously installed air conditioning units only need a little expansion to provide cool air for the IT equipment. Liquid cooling on the other side has many disastrous concerns, especially when introduced in the market. These concerns include:

-

Price range

-

Complicated Maintenance

-

Liquid leaks and their effects on an electrical facility like a data center.

-

Expensive maintenance

-

Huge power consumption

-

Component failure and malfunctions

-

Air pollutants

-

Humidity and condensation

-

Massive Carbon footprint

Increasing Demands

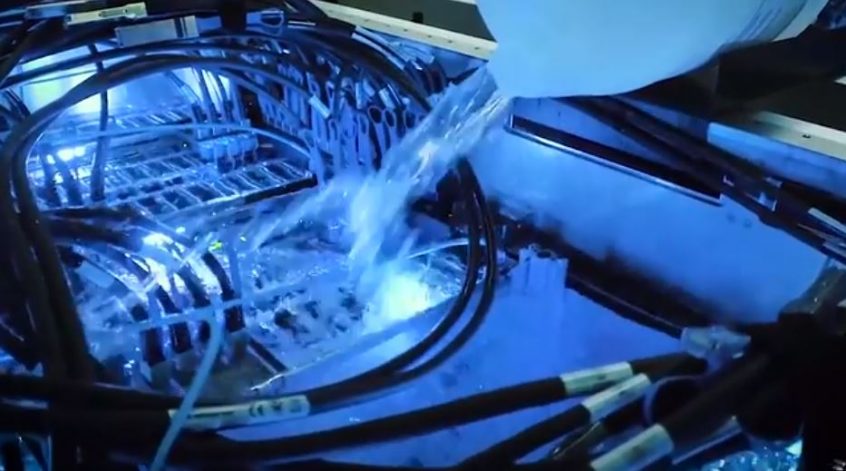

Retrofit Data Centers Into Liquid-Cooling

Environmental Impact and Energy-Efficiency

Photo Credit: totaluptime.com/

The growing number of data centers using liquid cooling can bring the infrastructure to the next level. Because many businesses realize the benefits of liquid cooling now, it is possible that in the next three years it will double in growth. Data centers could also use this proposition to attract customers. As many customers now are looking for sustainable and energy-efficient partner companies.

The Limitations of Air-Cooling Technology

Retrofit Data Centers Into Liquid Cooling

Most data center equipment is designed for air cooling and is not viable for liquid cooling. However, it will be better for the data center to completely convert into liquid cooling than to redesign its entire facility. In this case, it’s best to install an air to liquid Chilldyne Cooling Distribution Unit (CDU) as a first step before retrofitting the data center. This will allow for a liquid-cooled rack of servers utilizing direct to chip cold plates to be deployed without a dedicated liquid loop taken through the data center, and there is an added benefit of the liquid being controlled in smaller, more manageable volumes.

It’s a complex process to retrofit a data center into liquid cooling. However, data centers can always rely on The Green Grid, ASHRAE, and the Open Compute Project. They can assist from the compliance of construction materials to the actual implementation of the chosen liquid cooling method. Another option is the development of prefabricated modular data centers. This is where liquid cooling can be added to the facility without any reconstruction. many data centers can actually retrofit into liquid cooling right away. However, they still believe that they can be efficient with the best practices and optimal methods.

How Will The Transition Progress?

Photo Credit: https://www.gamingscan.com/liquid-vs-air-cpu-cooler

Of course, the transition from air cooling to liquid cooling would not happen overnight or a couple of days. There might be a transitional technology to help the industry into the inevitable change. This transition technology might just be in the form of hybrid coolers. Hybrid coolers can be more efficient than today’s air-cooled devices. However, data centers supporting hybrid coolers require at least two cooling plants. One is to cool the water that runs through the cold plates on the IT devices, and the other one is cooling the air-cooled loads in the building.

It’s expensive to provide for two plants and may have an impact on reaching return on investment. However, the best advances that can be made in the industry will occur when existing air-cooled data centers have reached their physical limit for cooling, and the only option for adding more capacity comes from refreshing the air-cooled IT in the data center to water-cooled IT equipment. Even if this change comes with the addition of plants to provide the cooling water to the new water-cooled equipment, the addition of this infrastructure is still more favorable than building new data centers from the ground up.

As those modifications become commonplace, the industry will see a clearer path to the purer, more leading-edge design of immersion cooling. That change will come in the next five years, it will dramatically change the industry, and we’ll check back again in ten years.

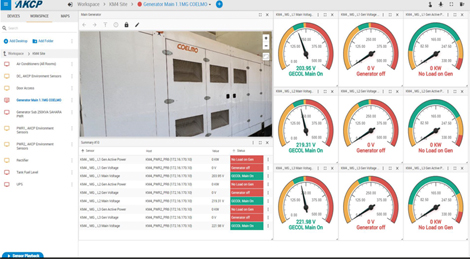

Liquid Cooling Monitoring

Monitoring and alarm are essential for any technology in the contemporary data center. AKCP Monitoring Solutions includes a software suite that provides monitoring, alerts, including temperatures, flow, pressures, and leak detection, and importantly can report into data center management software suites.

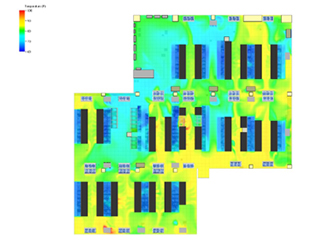

Temperature Sensors

The temperatures of the server surface, liquid bath, and inlet and outlet coolant inside the coils were recorded and measured by a wireless temperature sensor or K-type thermocouple.

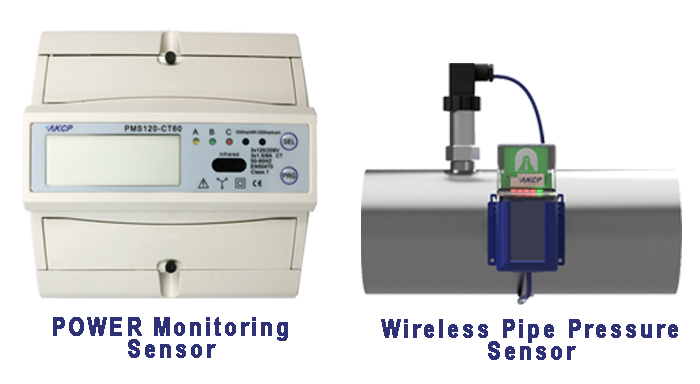

AKCP Power Monitoring and Wireless Pipe Pressure Sensor

Power Monitoring Sensor

The power of the cooling unit was monitored using a power meter that can monitor and record real-time power consumption. The AKCP Power Monitor Sensor gives vital information and allows you to remotely monitor power eliminating the need for manual power audits as well as providing immediate alerts to potential problems. Power meter readings can also be used with the sensorProbe+ and AKCPro Server lives PUE calculations that analyze the efficiency of power usage in your data center. Data collected over time using the Power Monitor sensor can also be viewed using the built-in graphing tool.

Wireless Pipe Pressure Monitoring

The pressure in the tank was monitored by an automatic pressure relief valve with a pressure sensor. Digital pressure gauge for monitoring all kinds of liquids and gasses. Remote monitoring via the internet, alerts, and alarms when pressures are out of pre-defined parameters. Upgrade existing analog gauges.

Wireless Valve Motor Control

Wireless, remote monitoring, and control of motorized ball valves in your water distribution network. Check status and remotely actuate the valves. Receive alerts when valves open and close, or automate the valve based on other sensor inputs, such as pressure gauges or flow meters.

Reference Links:

https://www.datacenterdynamics.com/en/opinions/20-years-of-liquid-cooling/

https://www.align.com/blog/is-liquid-cooling-technology-the-future-of-data-centers

http://green-data.blogspot.com/2016/08/data-center-design-raised-floor.html

https://www.acrjournal.uk/features/what-is-the-future-of-liquid-cooling/