Direct-to-Chip Liquid Cooling for Data Centers

In a world driven by soaring computational demands, conventional cooling methods are reaching maximum efficiency thresholds, both in terms of energy consumption and heat dissipation. Approximately 30% to 50% of data center energy consumption is attributed to cooling. There is an urgent need for innovative solutions. Direct to chip liquid cooling, sometimes called conductive or cold plate liquid cooling, is a game-changing approach that not only optimizes heat management but also revolutionizes data center operations.

Introduction

The surge in computational power requirements has put traditional cooling methods in jeopardy. Nearly half of the energy consumed by data centers is directed towards cooling. This has been amplified in recent years due to the advent of high-performance servers which generate substantial heat, and high density racks which pack many of these servers in a small space.

Spiraling electrical costs, demands for greener facilities have been a driving force behind innovative cooling solutions. One of the leading technologies is direct-to-chip liquid cooling.

Direct-to-Chip Liquid Cooling

Direct-to-chip liquid cooling is a cutting-edge approach employed in data centers to efficiently manage and disperse heat generated by high-performance servers. Unlike traditional air-based cooling, Direct-to-chip utilizes specialized liquid coolant to efficiently extract heat at the source. It differs from other forms of liquid cooling, such as the submersion method. The advantage is that unlike submersion, it doesn’t require specific hardware designed for the purpose. Existing chips can be retrofitted with cooling plates supplied by cold water.

If utilizing any form of liquid cooling in your data center, a water leak detection system would be of paramount importance. AKCP supply both spot and rope water leak detection that can alert via e-mail, SMS, and trigger siren and strobe light alarms in the event of a disaster. Contact us for a quote today!

Direct-to-chip Single Phase

With this method, fans are still required to move air through the server, removing the residual heat. although the requirement for air-cooling is greatly reduced. The coolant used can be water or dielectric fluids. Single phase refers to the fact that the liquid coolant does not change state, it remains as a liquid throughout the cooling loop never evaporating into a gas.

Direct-to-chip Two Phase

In contract to single phase cooling, two phase liquid cooling means that the coolant will change state from a liquid to a gas and back to liquid throughout the cooling loop. These two phase systems always utilize an engineered dielectric fluid. Two phase systems are more efficient at heat rejection than a single phase system. They do however have higher maintenance costs.

GIGABYTE OCP cooled by ZutaCore direct to chip liquid cooling

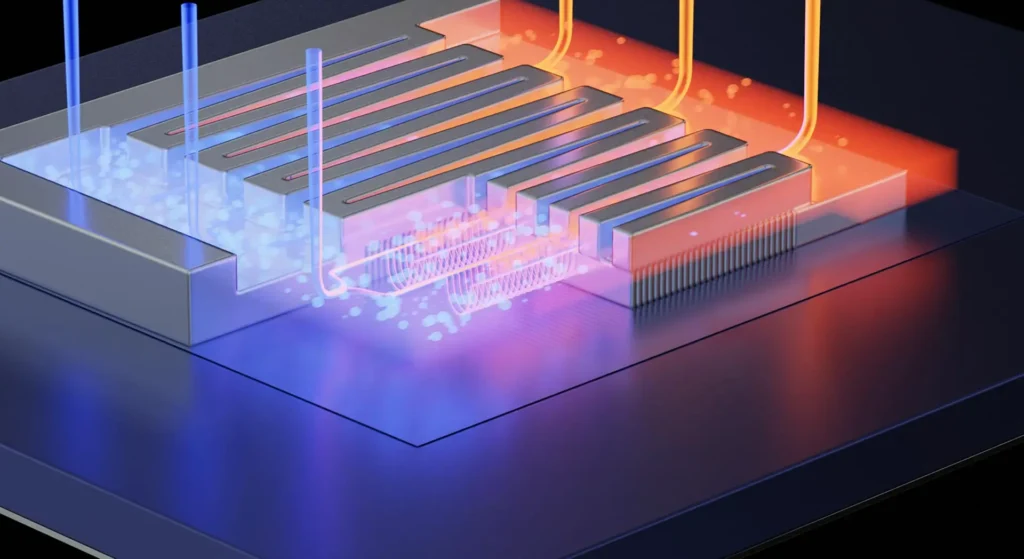

Direct to chip liquid cooling requires a network of microchannels or cold plates mounted directly onto the CPU and GPU. The liquid coolant travels through these channels, absorbing heat, which is carried away to a heat exchanger where it is extracted and dissipated to the outside. The water is then chilled with a mechanical compressor and returned to the chip.

Future Technology

There have even been experiments where by microfluidic channels are fabricated into the semiconductor chip itself, with no need for the micro channel cold plate. A team from Switzerlands EPFL University led by Remko Van Erp. The integrated channels etched into the semiconductor measure between 20-100 micrometers. These microfluidic channels were placed close to the specific transistor hotspots on the chip, delivering cooling to where it was needed the most.

By integrating microfluidic channels within a semiconductor chip, heat can be extracted from targeted areas using a cooling liquid. Credit: EPFL 2020

Achieving Remarkable Efficiency Gains

While submersion cooling cools the entire server, direct-to-chip liquid cooling selectively cools high-power components like CPU’s and GPU’s. With the potential to dissipate up to 80 kW per rack data centers can achieve up to a 45% reduction in cooling power consumption. This translates to meaning that a PUE of less than 1.2 is possible by eliminating a substantial portion of the mechanical air cooling.

Direct liquid cooling offers environmental benefits too. By repurposing waste heat for building heating systems and other applications, it further bolsters sustainability efforts. Noise pollution, often linked to air-cooled data centers, is significantly reduced by direct liquid cooling, resulting in a more conducive working environment for operators.

A Growing Demand

A 2023 study by reportlinker showed a growth of from $2.71 Billion in 2022 to $3.42 Billion in 2023. That is a compounded annual growth rate (CAGR) of 26.2%. it is expected the market will reach $8.46 Billion by 2027.

Direct-to-Chip Liquid Cooling – Industry Leaders

Advanced Thermal Solutions, Inc. (ATS)

Since its inception in 1989, ATS has emerged as a formidable player in electronics thermal management. Their comprehensive portfolio includes over 5,000 high-performance heat sinks, liquid cooling options, heat pipes, and design services. ATS is committed to energy-efficient operations and environmental compliance.

ATS is a pioneer of liquid cooling solutions. Their liquid cold plates boast superior thermal performance, outperforming conventional options by over 30%. They offer DIY and cost-effective tubed cold plates that efficiently cool components under varying pressures. They also have heat exchangers and a wide range of chillers, including thermoelectric and immersion-based varieties with precise temperature control.

ATS also provides flow meters and leak detectors for efficient monitoring and enhanced safety. Beyond its thermal solutions, ATS is an industry partner in technological advancement, driving progress in thermal management for more efficient, sustainable, and high-performance electronics.

ATS have 13 active patents on their technology and approximately 55 employees.

Asetek

Founded in 2000, Asetek has revolutionized thermal management in gaming hardware and cooling solutions. Their proprietary liquid cooling technology enhances performance, energy efficiency, and sustainability.

Asetek’s liquid cooling technology, which employs sealed-loop liquid coolers, has revolutionized thermal management, enhancing performance, energy efficiency, and sustainability. Their dedication to research and development is evident in ongoing improvements to pump designs, cold plate technologies, and more.

Asetek’s patented liquid cooling technology in data centers redefines energy efficiency and sustainability. By cooling processors at the source, their technology reduces data center cooling energy usage by up to 50%. Waste heat recovery is a standout feature. It allows data center operators to harness and repurpose energy for remote heating or electricity generation. Asetek offers innovative solutions such as the InRackCDU and Direct-to-Chip (D2C) liquid cooling technology to maximize heat dissipation and optimize data center performance.

Asetek’s D2C liquid cooling solutions offer benefits like enhanced density, energy efficiency, and reduced operational costs. Their liquid cooling innovations pave the way for greener and more efficient data centers, where energy efficiency and sustainability converge to reshape the future of thermal management.

Asetek are a publicly traded company (ASTK). Their total revenue in 2022 was 50.7 million, down from 79.8 million in 2021. They have approximately 157 employees.

JetCool Technologies

JetCool Technologies is a pioneer in advanced cooling solutions. Founded by a team of MIT engineers at the Lincoln Laboratory, led by Bernie Malouin, JetCool has emerged with a mission to revolutionize cooling by significantly reducing energy consumption, curbing water usage, and minimizing carbon footprints. At the core of their innovation is the microconvective cooling technology, which redirects fluid directly onto targeted surfaces to enhance heat transfer efficiency.

JetCool integrates its proprietary technology into an innovative cold plate design that supports thermal loads exceeding 1,000 watts. It presents a threefold reduction in thermal resistance compared to conventional microchannel cold plates. The SmartPlate™ System and SmartPlate™ Module offer fully sealed liquid cooling solutions that cater to data centers and edge applications.

Their liquid-to-chip solution, known as SmartLid™, facilitates direct fluid channeling to the processing chip. It effectively reduces thermal resistance and elevates thermal efficiency. This innovative approach eliminates the need for thermal pastes and interface materials, resulting in heightened power, efficiency, and device compactness.

Their JetCool’s SmartSilicon™ solution revolutionizes cooling within silicon chips, removing the dependence on thermal pastes or metal heat sinks. Tailored for CPU/GPU/ASIC chips, SmartSilicon™ enhances efficiency during chip fabrication, enabling superior performance without compromising design integrity.

Driven by a vision of future-proof design, optimized footprint, enhanced efficiency, and cost reduction, JetCool Technologies spearheads a transformative journey in cooling technology.

Jetcool are backed by $7.3 million of venture capital and employ 19 people.

Zutacore

Zutacore are headed by Erez Freibach. With a global footprint, headquartered in California, R&D in Israel, offices in Europe and Taiwan they are on a mission to lead the transformation to zero emissions data center cooling. Their HyperCool technology is a direct to chip, waterless, dielectric cooling solution. it is a two phase cooling technology that includes control software.

Zutacore have entered into a strategic partnership with Rittal, and are producing a high density, direct to chip cooled rack solution in conjunction with them. This is an of the shelf all in one solution for the needs of high performance racks that require liquid cooling.

Zutacore have 48 employees and are backed by private equity financing.

Direct-to-Chip Cooling still needs Air

The closed loop water chilled system delivers cooling directly to the specific chips that generate the most heat. These are usually the CPU and GPU’s of the computer. However, these may only account for 50% to 75% of the total power consumption. The rest of the computer, hard drives, memory chips etc still need to be cooled with conventional air cooling.

Monitoring for Optimal Efficiency

To address thermal risks and ensure maximum efficiency, AKCP offers complete data center monitoring solutions. Things can go wrong, and with direct-to-chip cooling there are risks associated with water leaks and potentially failures of pumps and chillers. When such a failure occurs the CPU and GPU can get hot very quickly as there is little airflow over the chips to cool them down.

Rack air inlet and outlet temperatures still need to be monitored and ∆T checked to ensure that servers are running at optimal efficiency. AKCP Thermal Map Sensors and AKCPro Server Heatmaps provide real-time insights into temperature variations at the rack level. These allow for identification of hotspots before they escalate. A comprehensive monitoring solution empowers data center operators to proactively manage thermal conditions. Operating the data center closer to the upper limits of ASHRAE recommendations lowers operational expenses, but leaves less margin for error. Hence, a comprehensive monitoring solution must be employed.

Conclusion: A Sustainable Future Beckons

As the demands for computing power grows, conventional air cooled methods falter both in terms of cooling capacity and energy efficiency. Direct-to-chip liquid cooling addresses these challenges, but also reshapes the landscape of data center operations. By partnering with industry leaders like ATS, Asetek, and JetCool Technologies, and leveraging solutions from AKCP, the future of energy-efficient and high-performance data centers is within reach.