Photo Credit: www.datacenterdynamics.com

Where do Power Quality Disturbances Come From?

Power Quality Standards

Here are a few Power Monitoring Devices:

-

1.Electricity Usage Sensor

-

2. Transmitter

- Bluetooth or Zigbee – both are short-range but are perfect for multiple purposes. Zigbee often utilizes a smart meter. But you cannot tap into a Zigbee signal without the correct gear.

- 433MHz – the same frequency employed by some remotes, weather stations, and other equipment. Can send data up to 70 meters away.

- Wi-fi – offers a wireless range over the two choices above

- Power Monitor Transmitters are often battery-operated.

-

3. Receiver / Display

Uses of Data Center Power Monitoring Systems

- Watch your energy consumption before you get saddled with an exorbitant power bill

- Optimize solar power provided on-site with solar PV panels

- Inform your family or colleagues about your electricity expenditures

- Discover your stand-by, after hours or overnight energy consumption

- Know early if the power company is overcharging you

- Discover the actual utility of your air conditioning, electric hot water, lighting, and more

- Learn to adjust your daily practices to help you conserve energy

- Lessen your reliance on fossil fuels and reduce your carbon footprint

- Improve PUE numbers

Waveform Capture

- The advantages of waveform capture are:

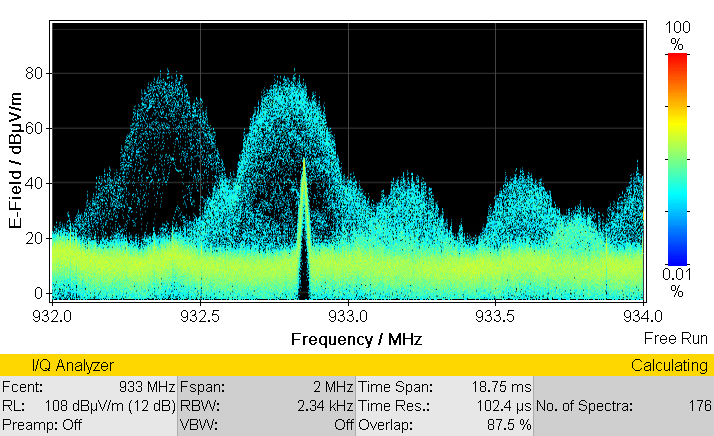

Photo Credit: www.narda-sts.com

- Precautionary load failure examination: