What is a Server Rack Blanking Panel

A server rack blanking panel is a piece of plastic or metal that fits into the empty spaces in your rack. Typically they come in 1U or 2U sizes, and they close off that U, only being removed when a new piece of equipment is to be installed. The fact that they will oftentimes end up being removed means that many people question their need as they will be surplus to requirements at a later date.

The fact is though, they are an essential piece of equipment, and once the benefits are understood the need for server rack blanking panels will become apparent.

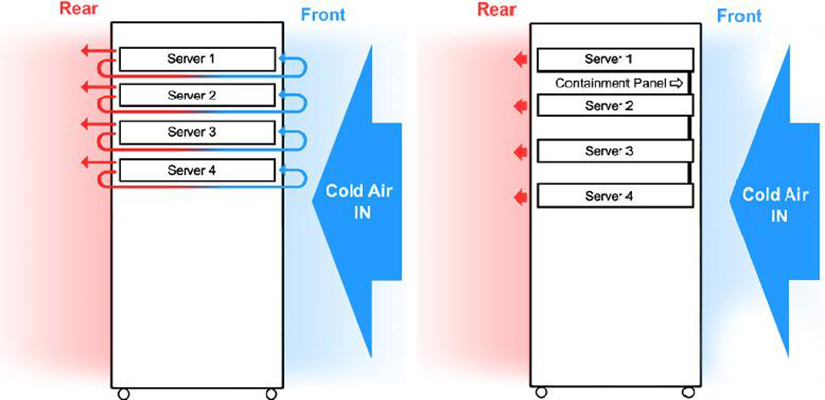

Proper Server Rack Airflow

Server racks help to direct airflow through the cabinet as the equipment mounted inside draws the air through. When the cold air passes over the hot components in the servers it carries with it the heat which is the expelled through a performed screen door at the rear, or sometimes chimneyed through the top of the rack. The rack is designed to ensure an even flow of air to remove heat as efficiently as possible. However, if there are open bays in the rack, it will disrupt this even distribution of airflow. When this occurs insufficient cold air may pass through the servers. Other results of this would be :-

- Dead Spots – When there is an open U in the rack, airflow will pass through the easiest path, the large openings provide an easier route than through the constricted pathway through a server. This results in dead spots where the air is not moving or moves slowly. These are also known as rack hot spots.

- Incorrect Airflow Direction – in a containment setup where hot and cold air is segregated into hot and cold aisles, any openings between these aisle can allow the mixing of air. Even without containment, the opening can allow hot air being expelled at the rear of the rack to re-circulate to the front and be sucked back into the server degrading cooling efficiency. Proper pressure differential must be maintained and can be checked with AKCP differential air pressure sensors.

- Tornado Effect – When air hits an opening it can spiral and blow in the wrong direction. This spinning air disrupts the cooling effects of the airflow.

- Reduction in Efficiency – Having areas of stagnant air and hotspots in your rack decreases the efficiency from the planned capacity. This results in extra loads being placed on cooling equipment and increased power consumption with the associated energy costs.

Server Rack Cooling

The above points illustrate the importance of utilizing blanking panels as part of your data center plan. Ensuring proper airflow management and cooling of your servers. Correctly utilized, blanking panels mean the air goes exactly where it is supposed to, aiding in efficiencies of cooling and power usage, improving your PUE numbers. The cost of blanking panels is minimal in comparison to the improved efficiency and lower energy costs than going without.

Another byproduct is a cleaner rack. The blanking panels prevent dust related issues. Although data center air is filtered, it is impossible to remove every bit of dust. Dust that finds its way into servers can be expelled at the rear of the rack. Blanking panels prevent this dust from being pulled back through the rack to the front and recirculated.

Finally, using blanking panels improves the aesthetic look of the data center, making your racks look professional and organized.

Blanking Panel Types

Blanking Panels can come in 1U or 2U sizes, and are also available with brushes to allow cables to pass through while maintaining the integrity of the blanking panels.

AKCP 1U Blanking Panel with cable Brushes