The global focus on sustainability has underlined the need to move toward more energy-efficient data center designs. These designs should provide the ideal combination of operational overhead reduction and reduced carbon footprints. The ultimate result is data center performance that is well optimized. When it comes to data center design, refit, and analysis to improve the efficiency and performance of legacy data centers, computational fluid dynamics (CFD) plays a critical role. It enables the operator to optimize racks, cabinets, cabling, and mechanical and engineering (M&E) equipment by simulating an infinite number of combinations.

Datacenter managers may be aware that in order to keep the servers, switches, routers, and storage units cool, they are physically blowing a lot of cold air into the aisles. What they don’t realize is that much of this air may be squandered. This squandered air is wasted money as well. From an environmental point of view, unnecessary cooling results in unnecessary energy use. When air is not used efficiently for cooling carbon emissions rise, hot spots will continue to be an issue, and equipment failures will occur.

Many data center managers recognize that something needs to happen in order to alleviate this untenable scenario, but they may lack a plan or strategy to do so. This is where CFD comes into play.

CFD is an effective way to analyze a data center. The adage “if you can’t measure it, you can’t manage it” still remains true when it comes to making informed decisions. In the case of CFD, though, the phrase “if you can’t measure it, you can’t improve it” could be more relevant.

What is Computational Fluid Dynamics Analysis?

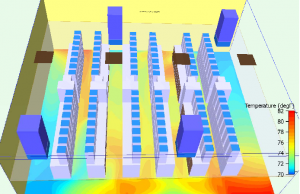

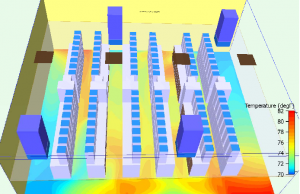

CFD software provides a 3D model of a data center’s physical properties, including the location and performance characteristics of cooling units, IT equipment, power systems, and other critical data center components.

Photo Credit: www.semanticscholar.org

This provides a complete, detailed thermal understanding of the data center, including physical layout, power equipment thermal dissipation, and rack power density, environmental conditions, cooling capacity, and air distribution efficacy. This is the baseline model, or “as is” snapshot, of the data center’s current state.

Additional CFD modeling will indicate how to optimize the operating environment while lowering energy and maximizing efficiency based on the information acquired.

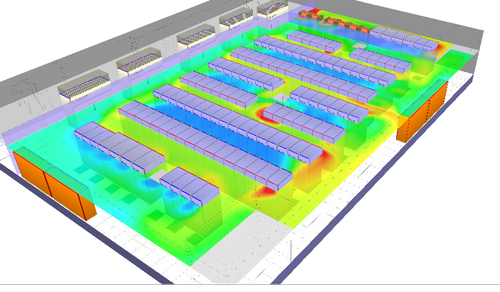

Assessment of the data center layout and performance; validation of proposed design changes; efficiency and reliability considerations; accurate prediction or simulation of the cooling design process; the ability to assess temperature and airflow modeling; and reconditioning for a cost-effective and energy-efficient design are just a few of the many advantages of CFD analysis.

Computational Fluid Dynamics Revolutionizing the Modern Data Centers

Computational Fluid Dynamics (CFD) is a popular topic among university students and engineers, but how is this thermal modeling technique applied in Data Center design? CFD is a numerical method that has been affecting the design process across the engineering field in recent years and has gained increased exposure.

CFD has become more prominent within the Data Center design process as a result of the expansion of Building Information Modelling (BIM) and the parallel progression that it brings to the industry. Because of the precision and availability that BIM provides to all stakeholders involved, CFD joins it in propelling the critical infrastructure business forward.

Prior to construction, CFD provides for quantitative estimates of a facility’s potential energy consumption and efficiency. This level of examination enables clients to get a functional understanding of the facility during the idea stage and establish the best operating parameters for their facility.

Engineers must create energy-saving solutions to stimulate the adoption of lower-energy alternative technologies as the effects of climate change become more evident throughout industrial applications. This is a major motivator for the expanding use of CFD in the design process.

Data centers will consume up to 20% of worldwide electricity supply by 2025. As a result of this prognosis, it is natural to extend the use of CFD to all aspects of Data Center design in order to smooth out any inefficiencies in the design process. In order to future-proof facilities, it is critical to address possible difficulties early on in order to build effective solutions with low Power Usage Effectiveness (PUE).

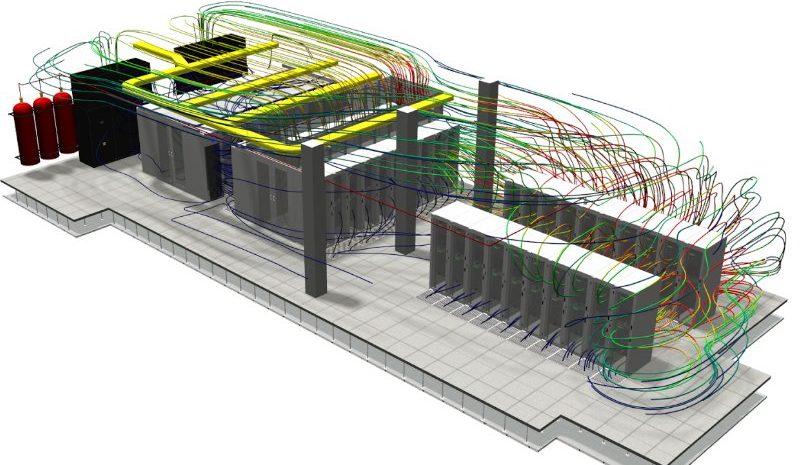

CFD enables precise decisions to be made regarding system settings and equipment location by simulating Data Centers and modeling their cooling systems, all of which may be done well before construction begins. This enables considerably more efficient resource use during the installation phases, as well as bringing more detailed decision-making earlier in the design process.

Customers come to Sudlows to audit and assess the operational conditions of their Data Centers, and the CFD department is a critical element of that process. With additional capabilities being developed on a regular basis, this capability now includes running control system optimization, automated algorithm implementation, and strategic planning in real facilities.

CFD has an ever-increasing presence in the design process, and it will continue to do so as new modeling approaches are adopted and the industry becomes more aware of it. Climate regulations may have an impact on CFD adoption, given the increasing push to cut global energy use across the industrial sector, as well as the unprecedented insight CFD models provide.

Risk Mitigation With Strategic Computational Fluid Dynamics Analysis

In today’s age of “Big Data,” data centers are the foundation of high-value mission-critical infrastructure.

A data center is a big building that houses a significant number of computer servers. The tremendous amount of heat produced necessitates a lot of space cooling. This high-density heat load necessitates sufficient cooling airflow to reach all computer components. Any interruption in the cooling air supply to the equipment increases the chance of failure due to overheating, or, in the worst-case scenario, a fire. All of this means that good cooling air circulation is critical for a safe and efficient data center operation. A Computational Fluid Dynamics (CFD) simulation of the airflow within a data center is the best technique to examine and predict the airflow design risk. All aspects of equipment configuration can be modeled and simulated using CFD, including:

-

Perforated Floor / Ceiling Tiles

-

Hot / Cold Aisle Containment

-

Diversity In Of Heat Load Distribution On Each Server

-

Underfloor / Overhead Plenum

-

Cold Air Lobby

To reduce risks, a variety of modeling simulations should be run to cover the data center’s expected operational modes, including the four basic analysis kinds listed below:

-

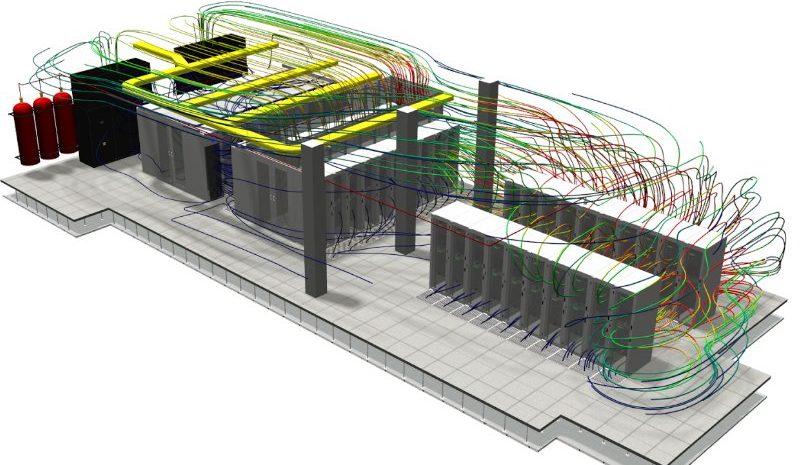

Design Airflow Analysis

Photo Credit: datacenterdynamics.com

The design heat gains in each server of the data hall are included in this baseline airflow analysis of the data hall with the cooling equipment functioning at its maximum level. This form of study gives you a picture of what to expect in terms of operational conditions. This has the ability to uncover a variety of concerns, including:

-

Damper Control for Supply Grilles

When all the supply plenum grilles are set at constant opening the air distribution can become uneven due to the pressure distribution in the supply plenum. CFD can help to identify the right opening area/control for each grille to ensure the most effective approach in achieving equal/requisite airflow through each grille.

-

Server Configuration

Identify high-powered servers within the data hall and quantify where high cold airflow is supplied.

-

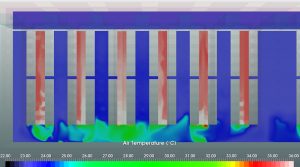

Hot Spots

Preventing cold air from picking up the heat before entering the servers.

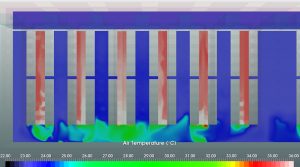

Photo Credit: www.iesve.com

Multi-tenant data centers are common in today’s data centers. As a result, the data center may be planned to satisfy a given heat load need, but this demand will not be met for many days, weeks, or months after the data center is operational. So, after setting numerous units as ’empty,’ the analysis can be used to determine the most cost-effective strategy to cool the units that are functioning. During the early stages of operation, this helps predict the operation and operating expenses.

-

Equipment Switchover Simulation

Data centers are built with redundant systems to ensure that activities can continue uninterrupted in the event of a disaster. Cooling machines bringing cold air into the data hall are one of the many potential failures. Due to the high-powered servers, a cooling unit failure would result in heat build-up and, in some situations, a potential fire hazard. This risk can even exist when the redundant secondary cooling unit is coming up and providing cool air. The outcomes of these failure situations will be determined through CFD simulations. The study can determine which cooling unit should serve as a backup so that if one fails, a hot spot does not develop, potentially causing equipment damage.

Multi-tenant data centers, like Day One Analysis, confront the difficulty of varying server use, as the entire server rack may not always be used. Blanking plates are often used to prevent airflow from entering empty rack slots. To decide which rack placements are preferable to leave empty, a Computational Fluid Dynamics analysis can be performed. When containment features are applied, this will help identify the effect of cold air leakage into the hot aisle or hot air leakage into the cold aisle.

CFD analysis is a relatively low-cost method of assisting design teams in planning for a variety of contingencies, allowing them to run as many different scenario analyses as they like prior to construction or at a later stage in order to minimize risks and mitigate potential failures in such a mission-critical environment.

AKCP Thermal Mapping

WIRELESS THERMAL MAPPING OF IT CABINETS

AKCP is the world’s leading expert on professional sensor solutions. Our R&D centers specialize in SNMP-based networking and embedded device technology. AKCP is the first company to bring a workable, LoRa based wireless monitoring system and wireless tunnel for critical infrastructure to market. With features specifically tailored for the data center.

Monitor the temperature differential between the front and rear of your cabinet. Datacenter monitoring with thermal map sensors helps identify and eliminate hotspots in your cabinets by identifying areas where temperature differential between front and rear are too high. Wired and Wireless Thermal Map Sensor.

With three (3) temperature sensors at the front and three (3) at the rear, it monitors airflow intake and exhaust temperatures, as well as provides the temperature differential between the front and rear of the cabinet (ΔT).

Advantages Of Thermal Map Sensors

Obstructions Within The Cabinet

Cabling or other obstructions can impede the flow of air causing high-temperature differentials between the inlet and outlet temperatures. The cabinet analysis sensor with pressure differential can also help analyze airflow issues.

Server And Cooling Fan Failures

As fans age, or fail, the airflow over the IT equipment will lessen. This leads to higher temperature differentials between the front and rear.

Insufficient Pressure Differential to Pull Air Through The Cabinet

When there is an insufficient pressure differential between the front and rear of the cabinet, airflow will be less. The less cold air flowing through the cabinet, the higher the temperature differential front to rear will become.

Power Usage Effectiveness (PUE)

When the data is combined with the power consumption from the in-line power meter you can safely make adjustments in the data center cooling systems, without compromising your equipment, while instantly seeing the changes in your PUE numbers.

Conclusion

One of the major benefits of using CFD modeling and analysis is that it can quickly demonstrate how a containment solution will immediately reduce a data center’s energy cost and lower its environmental footprint.

Regardless of which type of containment is used, large energy savings can be achieved by optimizing the airflow and raising the supply temperature, while simultaneously eliminating hotspots. Additionally, containment improves the benefits and economic feasibility of other efficiency measures, such as digital scroll compressors, electronic commutation (EC) and variable speed drives, data center infrastructure management (DCIM) software, and building controls.

Containment also saves energy by isolating the cold supply air from the heated exhaust air, lowering running expenses. Yes, there is an upfront cost to install the containment solution, but with a potential return on investment (ROI) of 10-14 months, end-users will quickly see a return on their investment. Furthermore, they will save energy, reduce operating expenses (OPEX), and reduce carbon emissions to become more sustainable from that point on.

Reference Links:

https://www.mdpi.com/1996-1073/11/3/644

https://www.simscale.com/blog/2018/05/data-center-power-consumption/

https://silo.tips/download/cfd-simulation-enhances-a-data-center-s-expansion-process

https://asmedigitalcollection.asme.org/heattransfer/article/132/7/073001/451420/Airflow-and-Cooling-in-a-Data-Center