Ensuring uptime is vital for data center operations. With huge volumes of data being processed through data centers worldwide, the banking system, businesses, and governments are relying on data center uptime to function. Hotspots cause downtime and thermal cameras can be used to quickly identify problem areas.

A high-density data center will have multiple layers of IT infrastructure. The installed hardware facilitates the transfer of data through the system. Servers process data and store it as needed.

However, despite regular maintenance and monitoring, potential issues can be missed. As complex as IT systems are threats may arise under the radar. Unable to detect such risks can be detrimental to the whole operation.

Surveillance with Thermal Imaging Cameras

Photo Credit: network-data-cabling.co.uk

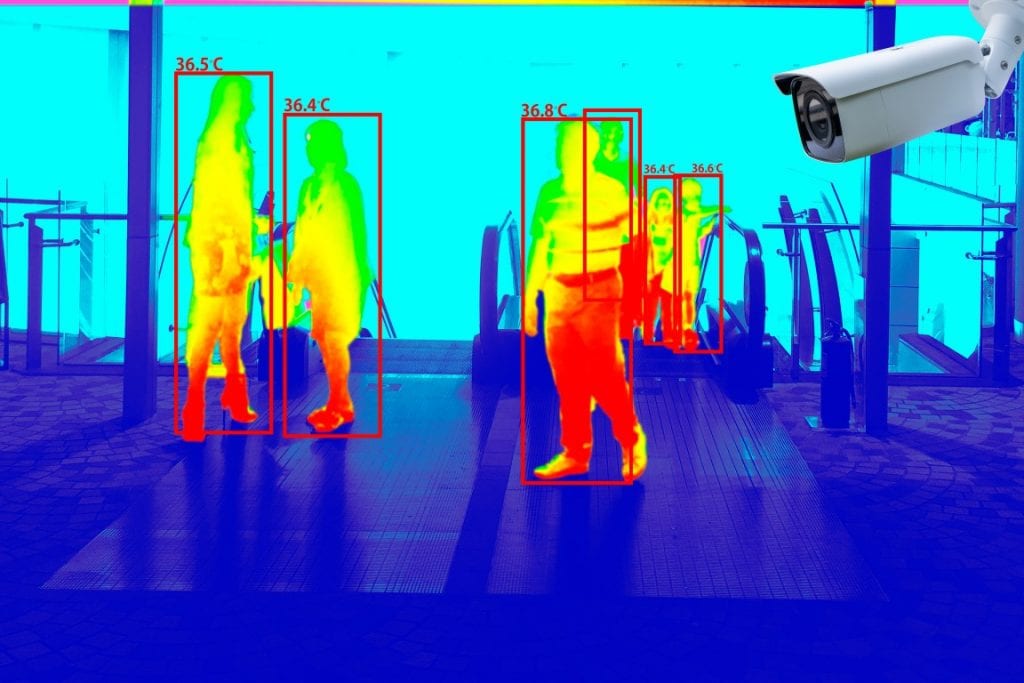

Thermal camera surveys are part of operational compliance for many organizations. They have become common in the post covid world to check employees and the public when entering malls, sports events, and the workplace. Thermal cameras are also valuable tools that any data center management can use.

Also referred to as infrared (IR) cameras, thermal cameras capture videos and images in the Infrared spectrum not visible to the naked eye. Like a snake who sees in the dark using Infrared, the cameras show the reflected heat signature of objects. Infrared cameras can capture images of the following:

- A person entering a building

- Substation transformers

- LV switchboards

- Critical power sources

- Batteries and other power distribution units

- HVAC, including chillers and individual cooling units

What Are The Benefits Of Thermal Camera Surveys?

Thermal camera surveys are either a standalone function or complemented with existing monitoring processes. The direct impact is visible when camera surveys are done alongside preventive maintenance procedures.

-

Detection of Hotspots

Within a server rack, high-temperature accumulation can be a problem. These areas are referred to as hotspots. Hotspots are the results of poor airflow management. Also, it can result from impractical server layouts.

Identification of hotspots is easy through a thermal camera. Images are captured and stored in a cloud. Such a storage option enables the easy relay of camera images. These hotspot images are also an essential account requirement for thermal audit records. Added to that, it presents temperature change within a given period specific to IT hardware.

The image accounts are a quick reference to evaluate if an investigation needs to be done. It also qualified evidence to perform any maintenance procedure. It will serve as an indicator of the need to upgrade the IT facility.

-

Image Records

More in-depth than detection of hotspots, image records serve as a gauge to analyze surface temperatures. Some thermal cameras can also yield two-dimensional images, which is helpful to compare and contrast temperature levels.

Analysis of these image records yields better identification of anomalies and threats. It provides a concrete report on the temperature status of an IT component. Image records are also preventive variables to tackle potential risks. If not responded immediately, these risks will become huge issues that may result in data center failure in the end.

Checklist For A Thermal Survey In A Data Center

There is a standard guideline in administering thermal camera surveys. The primary prerequisite is for a qualified engineer to conduct the thermal survey. It also has to follow a set procedure. In the case of data centers and IT infrastructure, a comprehensive survey is necessary. A thorough survey will single out potential and ongoing failures that may have been missed out from regular maintenance checks.

Usually, surveys are carried out from the incoming point. It will then trail into the critical power and cooling route. This will lead into the server room. An essential aspect of the survey procedure for data centers is to recognize the timing of its conduct. It is a priority to survey during peak hours. This is to take into account the peak operation and workload run of IT components. As such, the probability of getting a comprehensive heat image capture is high at this particular period.

-

Substation Transformers

There are varied types of transformers. Some transformers are installed just outside a data center building. A few of them are owned by local electric providers. There are also plant registered transformers. Despite the nature of these transformers, checking them during thermal surveys is imperative.

Checking transformers is rounding up the changes in thermal temperature in general. Monitoring will take into account windings and lug connections that are contributory to temperature fluctuations.

-

HV/LV Switchboard

Switchgears will always require maintenance. Switchboards, on the other hand, need checking after a long period. Capacitors in active harmonic filters require a change every 7-8 years. The survey will prevent temperature rise in switchboards. Consequently, these temperature increases will fasten the aging of a component. Thermal surveys are methods to determine if switchboards will require swap out.

-

Electrical Wirings And Sub-Distribution Panels

Power is transmitted on sub-distribution panels. Electrical cables connect these panels through circuit breakers. Proper cable sizes are critical to gauge the correct voltage and current flow. When thermal temperatures in these electrical wirings are higher than the regular reading, overheating is possible. Thermal surveys will track such temperature levels. It can also check for fault paths that can result in short circuits.

-

Backup Power, AMF Panels, and Static Transfer Switches (STS)

Photo Credit: blog.e-i-eng.com

The thermal image captured during the survey will record the standby and power-on temperature of backup generators. It is crucial to ensure that temperature does not hike beyond thresholds at rest and during run-time. Other than backup power, a similar method is necessary to check static transfer switches.

-

UPS Systems And Batteries

Load conditions of UPS and batteries need to be measured during the survey. This is to avoid a change in power intensity during use. It is part of the primary power protection plan to ensure an uninterruptible power supply.

-

Energy Storage Systems

Photo Credit: pmrpressrelease.com

An energy storage system functions the same as that of a UPS system. They are of lithium-ion battery in nature. Lithium batteries especially need annual checking as they are more complex than lead-acid batteries. A thermal camera inspection is also a means to yield income as energy demands come in.

-

Power Distribution Units (PDU)

In a server rack, PDUs serve as the last PowerPoint of connection of the server. Because server racks are prone to hotspots, this can detrimental to existing PDU. Thermal overloads are the effects of these hotspots. When overload happens, it can hamper power reliability. The thermal survey can detect occurrences of these overloads. It can also pick out wiring faults that are also aggravating thermal loads.

-

HVAC System

Photo Credit: blog.keepe.com

Just like power sources, a cooling system is an integral survey checkpoint. Surveying cooling units should comprehensively include cooling sub-components. It needs to check external chillers and heat exchangers as well. The survey can track failure points in the cooling system as a result.

-

Server Racks And Containment

A quick and accurate assessment is the byline of thermal imaging. These assessments are efficiency gauges on how cooling is done within racks and containment systems. One primary consideration in doing a thermal survey is the air intake and exhaust areas. These are attributed to power densities and heat generation.

Server rack surveys should also identify the operational capacity of the rack’s airflow. This will provide determinable proof of whether the cold and hot aisle is mixing. Doing thermal surveys along with airflow checks can thoroughly monitor airflow in server areas.

-

Raised Floors And Ceiling Voids

The data center layout is also prone to hotspots and varying temperature loads. Raised floors and ceiling voids are design ideas to facilitate better cooling and airflow. However, as the operational demand rises, the layout can only do so much. This is where thermal images help identify thermal issues. These issues can derive from many factors such as cable damage, connection faults, and even wrong area layout.

Integrating Thermal Camera Solutions In Data Center Operations

Thermal camera monitoring has adapted to many demands in data center make-up. As such, particular specifications are intended to customize a design for specific usage. AKCP remote camera monitoring technology has the same capacity to survey all possible checkpoints in the data center.

AKCP Cameras can connect through SecurityProbe base units. This can enable remote site monitoring. The base units harness the capacity of cameras to do surveillance and complement it with sensors’ ability to gauge temperature levels. AKCP cameras have access control that guarantees video security.

To get the most comprehensive thermal survey, SecurityProbe is an advanced environmental sensor monitoring device. When connected with the AKCPro server, users have overall access to many monitoring parameters. This includes a video playback window, sensor events display, and standard image capture.

Detect Hotspots In Your Cabinet with Thermal Map Sensor

Datacenter monitoring with thermal map sensors helps identify and eliminate hotspots in your cabinets by identifying areas where temperature differential between front and rear are too high. Thermal maps consist of a string of 6 temperature sensors and an optional 2 humidity sensors. Pre-wired to be easily installed in your cabinet, they are placed at the top, middle, and bottom – front and rear of the cabinet. This configuration of sensors monitors the air intake and exhaust temperatures of your cabinet, as well as the temperature differential from the front to the rear.

Integrating these solutions in a data center operation addresses the increasingly complex demand for environmental monitoring. As data centers evolve into high-density facilities, an increase in thermal loads is inevitable. Preventive maintenance will only be a successful endeavor with proper solutions that supplements it. The use of thermal cameras in thermal audits and surveys is vital addition to ensure data center sustainability. It proves that despite being low-cost, its comprehensive monitoring coverage and in-depth image capture are indispensable aid to improving data center operations.

Reference Links:

https://www.serverroomenvironments.co.uk/blog/thermal-camera-surveys-for-critical-data-centre-systems

https://aptsoundtesting.co.uk/wp-content/uploads/2018/07/Infrared-Thermal-Inspection-Survey-Checklist.pdf

http://blog.e-i-eng.com/preventive-maintenance-checklist-for-electrical-distribution-systems-in-commercial-buildings

https://www.watsons-property.co.uk/thermal-imaging-technology/

https://www.abbeyconsultants.co.uk/commercial/thermographic-testing-and-surveys/