Change Is Coming

IT managers are using edge computing to enable high-bandwidth content distribution, the Internet of Things (IoT), and on-premise applications in practically every business.

Local edge computing is a component of a broader hybrid IT architecture that delivers bandwidth-heavy content and latency-sensitive applications closer to the user or data source.

With the growing emphasis on local edge computing, there’s more pressure than ever to choose the best uninterruptible power supply (UPS) for this application.

It’s vital to choose the correct UPS to keep the system running and secure. General UPS issues like footprint, weight, battery replacement frequency, efficiency, and energy cost can have serious financial ramifications for deploying edge computing must be considered.

Learn more about Uninterruptible Power Supply (UPS) issues at the local edge and how the three technologies listed below address them:

- Broadband technology

- Technology for lithium-ion batteries

- Technology for cloud-based management and monitoring

We detail how each technology works as well as its distinct advantages. Then we show you some UPSs that incorporate these technologies. Finally, we compare a new Hybrid-Conversion On-Line UPS to a standard, double-conversion On-Line UPS in terms of the total cost of ownership (TCO).

Uninterruptible Power Supply (UPS) Challenges At The Edge

Local edge deployments are becoming increasingly common as IT operations become more complex. Unfortunately, important UPS features including footprint, weight, efficiency, energy cost, management, and maintenance are frequently overlooked.

This oversight leads to some of the most typical issues that edge computing environments encounter. These issues are amplified when edge deployments are repeated hundreds or even thousands of times, spending more time, energy, and, ultimately, money. These difficulties include:

- The UPS consumes an excessive amount of IT rack space.

Photo Credit: www.wwt.com

- The UPS is too hefty to be installed by one person.

- High-temperature battery degeneration necessitates frequent battery replacements.

- The service life expectancy of valve-regulated lead-acid (VRLA) batteries necessitates periodic battery replacements.

- Inefficient UPSs result in higher energy consumption and carbon emissions.

- UPS fleet status ignorance might result in downtime.

- UPS maintenance and management are problematic due to a lack of on-site personnel.

We discuss each of these challenges in detail next.

The Uninterruptible Power Supply (UPS) Requires Too Much IT Rack Space

IT is frequently implemented in tight locations like closets or break rooms using compact, wall-mount racks at local edge sites. When a UPS is too tall or too deep to deploy at a site, there isn’t enough U space in a rack or extra space for growth.

The Uninterruptible Power Supply (UPS) Is Too Heavy For One Person To Install

Heavy equipment, such as UPSs, may require additional manpower and resources to guarantee that personnel lift and move the equipment safely and without causing damage to the equipment. The risk of injury to employees is affected by factors such as how high and how often an object is raised. The National Institute for Occupational Safety and Health (NIOSH) in the United States, for example, has created a model that forecasts the risk of injury and sets a maximum weight restriction of 51 lbs./23.1 kg. for one-person installation in certain circumstances. UPSs frequently surpass this level, necessitating the use of numerous individuals for a safe installation.

Frequent Battery Replacements Are Needed Due To High-Temperature Battery Degradation

One element that affects UPS battery aging and can lead to premature battery failure is high ambient temperature.

Higher temperatures speed up the chemical process within typical VRLA batteries, speeding up water loss and corrosion. One of the reasons VRLA batteries need to be replaced more frequently than newer battery technologies is because of this. This is usually not an issue in settings with specialized air conditioning.

Periodic Battery Replacements Are Needed Due To VRLA Battery Service Life Expectancy

The service life of a battery varies depending on the chemical and manufacturer, although VRLA batteries typically last 3-5 years. Life expectancy is determined by several factors, including ambient temperature, discharge depth, and amount. If you estimate an edge computing site would last 10 years, you’ll need to change the batteries two to three times during that time. You can imagine how difficult it will be to coordinate battery replacement visits if you had 1,000 edge sites, all with distinct operating conditions and UPS ages.

Inefficient Uninterruptible Power Supply (UPS) Emits Higher Carbon Emissions

Although the energy spent by a single UPS may not appear to be significant, when a fleet of UPSs is deployed across numerous sites, the cumulative energy and carbon effect can be significant. Electrical “losses” exist in all UPSs, which means that not all of the input energy reaches the important IT loads. The heat created by electronics such as the inverter and rectifier, transformer heating, and battery charging losses are all examples of losses.

Lack Of Knowledge Of The Uninterruptible Power Supply (UPS) Status Can Lead To Downtime

The greater an organization’s UPS fleet, the more difficult it is to understand the massive numbers of alarms and status change messages. A poor situation is made worse by not knowing about an issue until there is an alert or downtime. Uncertainty about whether unauthorized employees are accessing the UPS locally in real-time can lead to greater downtime risk. Being ignorant that UPS software and firmware are out of date and do not incorporate the latest protection can cause security hazards from a cybersecurity standpoint.

Lack Of On-Site Staff Makes Maintenance And Management Of Uninterruptible Power Supply (UPS) Difficult

Uninterruptible Power Supply (UPS) components can fail for a variety of reasons. It is more difficult to troubleshoot problems without IT or facilities staff on-site, which is typical of most edge sites. Maintenance is often an afterthought made worse when UPSs are spread over many geographically dispersed sites. For example, a UPS battery is shipped to a retail store for replacement in the back room, but none of the on-site staff know what it is or what it is for and the battery remains in the box and never gets installed.

Three novel solutions can overcome the UPS difficulties listed above:

- Broadband technology

- Technology for lithium-ion batteries

- Cloud-based administration

We’ll go through each of these technologies in detail in the next chapters.

Wide-Bandgap Technology

Photo Credit: www.researchgate.net

When the power goes out, the Uninterruptible Power Supply (UPS) transforms the DC energy from the battery to AC power to power the IT load equipment. Power electronics – devices and circuits that control and convert electric power – enable this power conversion.

Power electronics of an On-Line UPS convert the AC input voltage to an intermediate DC voltage, which is subsequently converted back to an AC voltage on the UPS output. A set of high-frequency switches conduct these transformations. These switches are either silicon-controlled rectifiers (SCR), insulated-gate bipolar transistors (IGBT), or metal-oxide-semiconductor field-effect transistors (MOSFET) in most UPSs.

Semiconductors, which can operate as both insulators and conductors, are essential in applications that switch energy flows. In other words, they can both block and allow electron movement.

The problem with semiconductors is that they aren’t perfect gadgets. As a result, they endure heat-related power losses. In fact, the faster they are swapped, the more losses they incur. This fact contradicts the goals of a UPS, which are to generate a smooth sinusoidal AC* output voltage while reducing losses.

So, How To Lessen Switch Losses?

The bandgap is the difference in energy between electrons in a substance that are not free to move and those that are energized and free to move. A physically thicker semiconductor layer is required in traditional silicon-based technologies. Higher resistance and higher conduction losses are connected with increased thickness.

Another drawback of silicon-based power electronics is their inability to function well at higher temperatures, resulting in current leakage and power loss. Silicon devices typically have a maximum temperature limit of roughly 150°C.

In today’s technology world, silicon devices have reached their limit, and new technology in the semiconductor sector dubbed wide-bandgap has arisen to provide breakthroughs in power electronics with superior features.

Wide-bandgap semiconductors, such as Silicon Carbide (SiC) and Gallium Nitride (GaN), have a larger energy gap between the valence and conduction bands than pure silicon. Because of the larger energy gap, they have higher electron mobility and can function at higher switching frequencies than silicon-based semiconductors.

In addition, because energy loss is considerably reduced compared to silicon materials, this technique produces less heat in high-voltage applications without causing damage. For a given voltage, SiC and GaN have a higher thermal capacity than typical silicon. As a result, cooling needs in systems with wide-bandgap devices can be reduced.

How This Addresses Challenges At The Edge

- Supports Smaller Power Electronics

Wide-bandgap technology enables electrical devices to be more compact and power-dense than silicon-based electronics. These compounds’ higher switching frequencies allow them to have physically smaller switches, reduced power losses, and smaller heat sinks, making thermal control easier. Finally, the reduced size of power electrical devices advantages the UPS, allowing it to take up less U area in the IT equipment rack.

- Enables Lighter Power Electronics

Wide-bandgap technology switching converters operate at higher frequencies. Not only does this result in a reduced footprint, but the substantial weight reduction also contributes to a lighter, easier-to-install UPS. The actual UPS weight varies depending on the type of wide-bandgap power electronics employed, although it is always lighter than Si-based electronics.

- Improves Efficiency Of Power Electronics

Power electronic devices that use wide-bandgap semiconductors can operate at greater voltages and frequencies with lower power losses. As a result, power electronic modules built using these devices are more powerful and energy-efficient than those made with traditional semiconductor materials, resulting in cheaper electric bills.

Lithium-Ion Battery Technology

Photo Credit: news.mit.edu

The most common energy source for UPS has been VRLA batteries. Lead-acid batteries face some disadvantages as compared to newer technologies on the market today, most notably a lower life duration of 3-5 years, excessive weight, and bulk.

These issues are being addressed by advances in the battery industry, particularly lithium-ion battery technology.

The metal oxide is used in the positive electrode of some lithium-ion batteries, while graphite is used in the negative electrode. These batteries’ most important component is lithium-ions.

Because of differences in their chemistries, as well as the quality of materials used and cell construction, there are many differences in performance between one battery and another of the same type, but they all have one thing in common: “lithium-ion.” These variations in battery design affect the battery’s overall performance, as we will discuss next.

How This Addresses Challenges At The Edge

- Supports A Smaller Footprint

Because of their great energy density, lithium-ion batteries often take up 50-80% less space than lead-acid batteries.

- Enables Lighter Battery Weight

Lithium-ion batteries are lighter than VRLA batteries of comparable energy capacity due to their better energy density, which results in a 60-80% weight decrease.

- Minimizes Battery Replacements Due To Longer Life Expectancy

The number of cycles a battery is fully charged and drained in a certain operating temperature range provided by the manufacturer affects its lifetime. A normal VRLA battery has a life expectancy of 3-5 years, whereas lithium-ion technology has a life expectancy of up to 10 years.

In UPS applications, lithium-ion batteries have twice the calendar life of lead-acid batteries – the expected time a battery will survive if it is trickle-charged for its entire life with no power outages at a set temperature, often 25°C. Under similar operating conditions, lithium-ion batteries degrade less than VRLA batteries, resulting in longer battery life.

- Improves Efficiency Of Battery Charging

A battery’s energy loss is divided into two categories: fixed loss from trickle charging and transient loss from draining or charging the battery after a power outage. In comparison to lead-acid batteries, lithium-ion batteries require less energy to retain a charge. On steady-state charging, the energy cost of a lithium-ion battery is half that of a VRLA battery, including cooling requirements to remove heat from energy losses.

AKCPro Server Cloud-Based Monitoring Technology

With the rise of organizations that rely more on edge computing, IT service availability has become increasingly important, as it has a significant influence on the business. During a power outage, valuable data and expensive equipment are put in danger. As a result, a dependable management and service system is required to assure the availability of vital equipment such as a UPS and to protect IT services from downtime. When a corporation has several Uninterruptible Power Supply (UPS) scattered all over the facility, the site staff are insufficiently trained, and the UPS are of varying ages, having an effective management system integrated within an Uninterruptible Power Supply (UPS) becomes even more crucial.

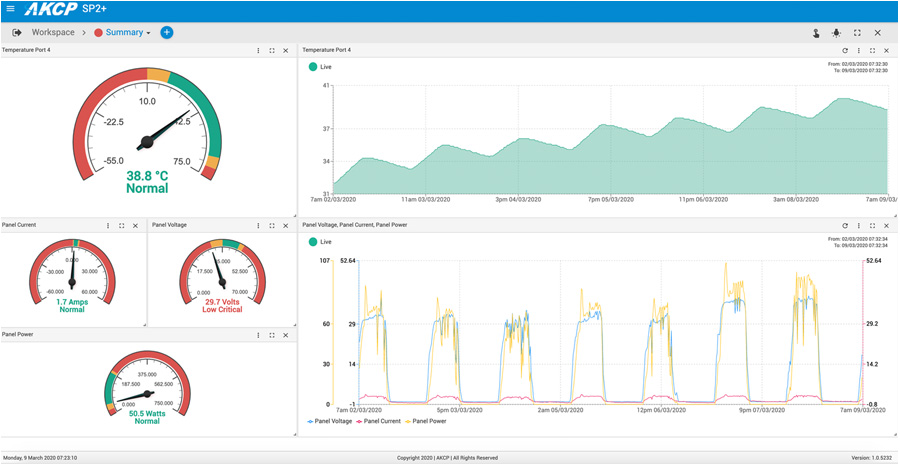

AKCPro Server, a cloud-based management and monitoring system, is a cutting-edge technology that uses analytics and new automated services to improve and optimize system management, for a number of sites. The software solution collects all data input for real-time monitoring and repair.

Multiple measures, such as maintenance and monitoring, can improve Uninterruptible Power Supply management in local edge computing. AKCPro Server offers proactive help to avoid future risks or reactively provides maintenance once a system failure has occurred. Businesses with local edge deployments can use this to upgrade their management from basic monitoring and alarms to a simple system that is more proactive and predictive.

Edge applications can benefit from cloud-based infrastructure to assist meet availability goals. By evaluating battery status or UPS load, preventing, and anticipating future failures, the UPS industry has embraced a cloud-based strategy to enhance the quality of the system’s status. This is usually performed by connecting a UPS smart connect ethernet connection to AKCPro Server to monitor and control alarms, maintain uptime, and check IT infrastructure status on-site or remotely.

How This Addresses Challenges At The Edge

- Improves Visibility And Knowledge About UPS To Minimize Downtime

Experts that are familiar with UPS can use safe and straightforward connected solutions to remotely monitor them. Users can also access predictive analytics and a dashboard view of their UPS fleet using the data transmitted to the cloud. They can decipher massive volumes of alerts and status change notifications, spot problems before they become a problem, and see who is accessing the system locally and remotely in real-time. By using read-only connections to the UPS, AKCPro Server management software technology gives vendor-agnostic remote visibility.

- Eliminates The Need For On-Site Staff To Maintain UPS

Without on-site IT or facilities workers, AKCPro Server allows operators to troubleshoot problems. Automatic notifications, firmware updates, and advanced support are all available through this full remote administration interface. It coordinates the dispatch of personnel when various locations require maintenance services.

AKCPro Server Central Monitoring Software

The world is becoming more computerized, and many businesses are focusing on IoT, cloud computing, and mobile apps, all of which necessitate resiliency at the edge. Traditional UPS, on the other hand, presents issues at the edge, such as carbon footprint, energy expense, and the danger of downtime. Fortunately, these problems can be solved by combining three technologies:

AKCP Battery Monitoring

Wireless Battery and Solar Monitoring

Someone manually checking the battery string once or twice a week would be a simple manual battery temperature monitoring system. This can be done with an IR temperature gun, and the data can be recorded in a spreadsheet. Remember that the temperature difference between the battery and the ambient temperature should not exceed 3°C.

Why not construct a permanent 24/7 battery temperature monitoring system in these days of automation? The most simple is a temperature sensor mounted on the battery’s negative terminal post. You’ll have a temperature graph, and with the addition of an ambient temperature sensor, you can plot the two on the same graph and see the T. Individual cell temperatures, charge current, voltage, and load current and voltage can all be monitored by more complex battery monitoring systems.

AKCP Wireless Remote Monitoring

- A trustworthy wireless monitoring system that can successfully monitor environmental conditions will prove to be a worthwhile investment in the long term. To meet all data center demands, AKCP offers a variety of wireless sensors, including battery sensors, cabinet temperature, and humidity monitors, air pressure differential sensors, airflow sensors, water leak sensors, and more. Offers remote monitoring and alerts, diagnostics with valuable recommendations, predictive analysis, remote administration capability, and access to service specialists.

Reference Links:

https://blog.apc.com/2022/02/07/its-time-for-smaller-more-powerful-ups-edge-computing-sites/

https://www.sourceups.co.uk/how-to-overcome-the-challenges-of-edge-computing/