Overseeing a controlled environment is a prerequisite for a reliable data center. Temperature is one of the most extensively monitored parameters by data center administrators. Fluctuations can cause rapid equipment failures. Ambient temperature monitoring ensures the room temperature threshold within a given period of time. However, the air temperature also varies from rack to rack. Based on Gartner, a rack costs approximately $70,000, excluding the business and operation costs. Can you imagine losing this huge amount? Hence, relying on ambient temperature monitoring solely could risk your business continuity. Rack temperature monitoring should also be part of the overall monitoring scheme.

What Should Be The Rack Level Temperature?

The American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) provides temperature guidelines for rack temperature monitoring. The inlet and outlet temperature standards are specified. It recommends an inlet temperature within the range of 18°- 27°C / 64°- 80°F. The outlet temperature should be less than 20°C or 35°F compared to the inlet temperature. The administrators must adhere to this standard to achieve the utmost reliability.

Rack Cooling Index (RCI)

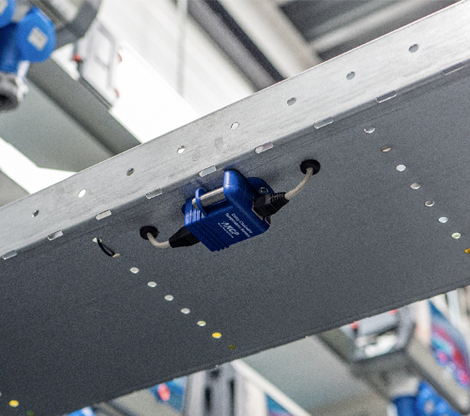

Photo Credit: www.rfcode.com

The Rack Cooling Index (RCI) measures the effectiveness of the rack cooling method. It is maintained based on the data center thermal temperature guidelines and standards. Calculating it will determine if the temperature of the rack is still in compliance with the ASHRAE. The Index is designed to help assess the equipment room health for managing existing environments or designing new ones. It can also be a design specification for new data centers.

Why Is Rack Temperature Monitoring Important?

Rack temperature monitoring prevents unwanted incidents from happening. A data center consists of servers and equipment that exhaust hot air. Inadequate cooling and poor airflow can make the inlet temperature rise. On the other hand, low temperature increases humidity. In any of these events, equipment failure will surely happen, affecting the whole business operation.

- Quick Identification of Heat Problem

- Rack temperature monitoring will help in identifying the heat problem within the facility. It allows the administrators to act promptly. For instance, the air conditioning units will begin to make up as soon as the temperature increases. Ambient temperature sensors will notify if the cooling is already insufficient. By this time, equipment is suffering for a long period already. And as an administrator, risking the business by wasting time is not an option.

- Preventing Hotspots

- Another importance is identifying the potential hotspots. These happen when the equipment has a higher air intake, causing the temperature at the server rack to rise. Hotspots are a combination of airflow deficiencies and rack layouts. Temperature monitoring ensures proper airflow within the server rack, which could be up to 47U (2m) in height.

- Maximizing Equipment Life Span

- Heat rises, so equipment at the top of the rack is at risk. As it is known, heat can shorten the lifespan of the equipment. It can primarily affect the battery and CPU. For every 1-degree excess on the required temperature, the life of a lead-acid battery is lessened in half. High temperatures can also cause the CPU to melt down.

- Prevent Mold Growth

- The combination of high humidity and low temperature is a favorable condition for mold growth. Molds can grow on the racks and servers’ motherboards. Molds are small and fast-growing organisms making them one of the causes of stress for data center administrators. Rack temperature monitoring ensures the optimum temperature and prevents molds from leaching on the racks and equipment.

How To Manage Server Racks?

An upsurge in temperature can happen at any time and anywhere within the facility. Perhaps, some protocols are applicable when this transpires. But, administrators of a critical-mission facility should not wait for this to happen before taking action. Proper management of server racks to avoid complications is a must before running a data center.

- Sufficient Ventilation

- Secure a ventilated server rack by installing switches at the top of the server racks.

- Good Layout

- For high-density racks, it is important to use the hot or cold layout to ensure containment of the hot aisle and cold aisle. This layout creates a clear separate path for hot air and cold air allowing the equipment to pull in the coolest air.

- Choosing the Right Server Racks

- With the variety of racks available in the market today, choosing the right one could be challenging. The right server rack will prevent heat build-up, ensuring an efficient data center. When choosing a server rack, certain factors require consideration. These includes:

-

-

- Ventilation

- Encasements

- Materials

- Load Capacity

- Flexibility for Design Changes

- Customizability

-

- Proper Arrangement of Servers

-

- Racks need to be filled with servers without open slots. If some slots are left open, the air will flow into the opening, disrupting the air that needs to go through. Using rack filler panels to obstruct the open slots is a good solution.

Rack Temperature Sensor: A Solution

Administrators need to be alert in any circumstances within the facility. They need to be prepared for the potential issues affecting the equipment’s reliability. However, the temperature rise is an imperceptible occurrence making it a difficult task. A slight increase is impossible to notice unless it goes beyond the point that humans can feel.

A temperature sensor is a solution as it makes rack temperature monitoring easier. With proper placement, it can send a notification if the rack temperature surpassed the threshold. Real-time temperature is measured, allowing appropriate action at an early stage. As the sensor collects data on the environment, it will be converted into a record. Administrators can view this anytime to track patterns of temperature changes.

For data centers, it is more than knowing what’s currently happening. Administrators should also explore the future possibilities that might risk the equipment. While servers with higher temperatures operate more efficiently, a single mistake could turn into a catastrophe. Rack temperature sensors will let you know if the environment is still favorable to the equipment ensuring a catastrophe-free data center.

Rack Temperature Sensors Placement

AKCP Sensor Placement

Although servers have built-in cooling and ventilation systems, their reliability still depends on the environment’s condition. Moreover, each of them has different heat tolerances. This means the cooling demand of every single piece of equipment or rack could hardly be known.

Fortunately, the proper placement of sensors can be a solution. In rack temperature monitoring, sensors that are placed in the most appropriate location will deliver the most accurate result. When installing, it is important to place them closer to the points that you want to measure. It should also be noted to avoid direct airflow entering and leaving the equipment. These areas experience fluctuation most often.

There are three different models for placing temperature sensors according to ASHRAE. These are managing the space, setting up space, and troubleshooting the space. The rack recommends placing a minimum of 6 sensors or more for a high-density data center. They are located at the top, bottom, middle, and back. The sensors on the back aim to monitor inlet and outlet air temperature. For Gartner, temperature sensors can be placed at three points in the rack. These are the bottom front, top front, and top back of the rack, which has the highest temperature.

Shifting To Wireless

As innovation escalates, wireless technology introduces easier placement of rack temperature sensors. Wireless temperature sensors have countless advantages in terms of cost, accuracy, and accessibility. With its capabilities, no wonder most of the companies in the industry have switched to wireless.

Wireless Rack temperature monitoring not only saves cost for the construction during installation. It can also save labor costs. The recording is done in a more cost-effective approach since it does not require a worker to record manually. Additionally, the data center needs to function at full efficiency without interruption. This means that there is no room for problems caused by human error. With a wireless temperature sensor, there is no need to worry about the accuracy and validity of the data. Its accessibility is also one of the major reasons why the industry invests in wireless. The record can be accessed at any time regardless of proximity. It can also be sent through email, SMS, or any other application integrated with the system.

AKCP Wireless Temperature Sensors

AKCP offers wireless temperature sensors for more compendious rack temperature monitoring. With the amount of equipment within the data center, it is certainly critical. It requires precise data for better decision-making. And for AKCP, accuracy is not a problem. It can provide you with the most accurate data for a specified period. With this, you can be aware of “what” happens and “when” it happened.

Moreover, taking action a second too late will create a big impact on its reliability. You wouldn’t want this to happen for sure. Message our AKCP sales team now!

Reference Links:

https://www.vertiv.com/en-asia/about/news-and-insights/articles/educational-articles/rack-temperature-monitoring-the-secret-to-comfortable-data-center-equipment/

https://www.serverroomenvironments.co.uk/blog/how-to-manage-server-rack-temperatures

https://www.serverroomenvironments.co.uk/blog/how-to-install-server-room-rack-monitoring-systems

https://www.racksolutions.com/news/blog/how-to-server-rack-cooling/

https://dataspan.com/blog/data-center-temperature-sensor-placement/