The current data demands call for a more ardent IT infrastructure. To address these demands, many organizations are investing heavily in IoT and the likes of Big Data. The utilization of these high-density computing machines paves significant growth in data analytics growth. While growth is promising thanks to IT investments, a particular drawback is imminent. Data center energy simulation can help in meeting the demands for sustainable yet effective data centers.

The prioritization of sustainable goals surround our daily lives and is becoming a mainstream directive. Businesses must adhere to curb their harmful contribution to the environment. More than that, sustainable solutions also present less overhead for operational expenses. With lower operational input needed, lower costs are easily achievable.

One sustainable solution in the data center industry is the move towards energy efficiency. Data centers are making it a priority to design efficient systems. Many have shifted away from the traditional energy-intensive data center operations. The movement has now veered towards making data centers use energy more efficiently. Specifically, cooling systems for data centers are switching to natural energy sources. Some data centers with more capital leeway build their facility in colder climates. With colder environments, lower energy demand is necessary for maintaining data center temperatures.

Photo Credit: legendpower.com

Energy Simulation Plays The Part Towards Efficiency

It is relatively hard to shift data center systems despite knowing the course of action. Energy efficiency needs an evidence-based platform to support the need to change. Hence, energy simulation models are becoming a go-to method increasingly to plan things.

Energy simulation is a highly sought-after method to better understand energy flow for specific data center components. Capturing the primary energy harnessed by the data center building is one. Determining the energy characteristics of a planned infrastructure layout is another benefit.

Simulation software enables data engineers to run different iterations. A thorough view of probable energy performance is tracked by running multiple iterations. While it is easier said than done, the simulation needs sophisticated tools to do this. These tools should account for different energy characteristics such as heat transfer, air dynamics, and cooling effect. It should also provide data on materials fit for a particular data center arrangement. Detailed visibility is a vital takeaway from simulation.

Computational Fluid Dynamics

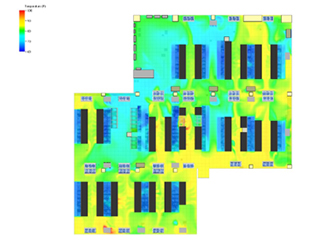

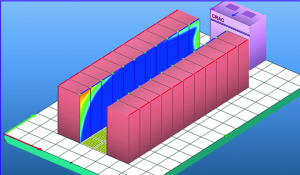

Photo Credit: springernature.com

A rather popular simulation method is computational fluid dynamics (CFD). CFD models the flow of fluid using numerical solutions. Because energy is hard to track, CFD helps analyze the interaction of these matters in a data center. CFD is used more extensively in engineering to model aero and hydrodynamics. It helps in gathering crucial data on air pressure and velocities.

How Is It Relevant To Energy Simulation?

Thermal energy can be simulated using CFD. Analyzing the different server room zones to understand temperature conditions is an example. CFD can provide imaging to view the potential temperature distribution in data center spaces. Providing such an image enables engineers to work around a better layout conducive to better temperature management.

Using The Cloud As A Simulation Platform

The development of technology solutions also reached engineering simulations. Because CFD deals with fluid behavior, specifically liquids and gases, 3D modeling is necessary. The use of 3D modeling provides three-dimensional visibility to engineers.

For example, CFD can provide a picture of how heat transfer happens. The mechanism of conduction, convection, radiation is captured using CFD. Having this kind of visibility provides better impact tracing of data center performance. But subscribing to 3D models requires a robust platform. Thus, a cloud CFD platform paves better simulations accordingly. Because modeling follows multiple iterations, a cloud CFD platform can provide simultaneous capacity to conduct multiple iterations in one go. Conducting simultaneous runs provide a comprehensive scenario probability at the same time.

How To Use CFD?

CFD follows 3-phases to fully accommodate a modeling requirement.

- Pre-Processing

Initially, a problem statement is a prerequisite to modeling. Integrating the problem statement into a computer model takes precedence in CFD terms. Accounting for the problem statement involves noting assumptions. Assumptions should exhaust all potential concerns to be modeled.

- Solving

Solving requires computational power. Actual computations are done to quantify indicators. Indicators are specific to the modeling conditions one has assumed. There are available and accessible sources of CFD solvers online. However, take caution as precision and breadth vary as well.

- Post-Processing

The post-processing phase is where visualization happens. This is the phase where results are verified based on graphic imagery. Image can be static or moving depending on the CFD software in use. With a clear depiction of scenarios, a conclusion can be raised already.

Useful Gains From CFD

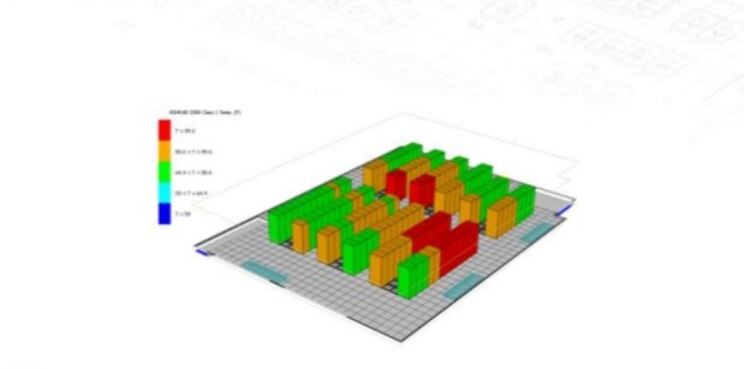

Photo Credit: slidesharecdn.com

The benefits provided by integrating CFD into the whole data center planning should not be underscored. As such, there are many gains from using it.

- Understand flow characteristics to spot inefficiencies such as air recirculation and hotspots

- Analyze the distribution of air in different data center space

- Collect regular equipment temperature reading

- Provides a comparison of as-is designs to to-be scenarios

Some particular data center components can specifically undergo modeling through CFD.

- CAD models of different parts

- IT equipment

- Server including cooling fans

- Air inlet and outlets

- Other ventilation sources

- HVAC equipment

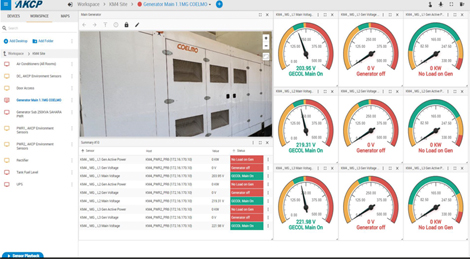

Boosting CFD Modeling Using Monitoring Software

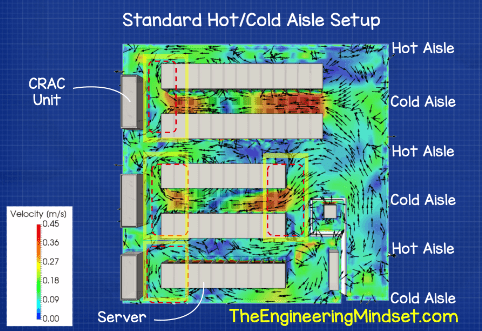

Photo Credit: theengineeringmindset.com

CFD and monitoring are used interchangeably in data center operations. While they are different, they complement each other in operational impact. In principle, CFD predicts scenarios while monitoring and sustaining good conditions. Both CFD and monitoring are prime movers of energy reduction in the process. Energy simulation is best supplemented with monitoring action to sustain the best preconditions.

One best complement of a sound monitoring endeavor is investing in suitable sensors. Recording the real-time temperature of the data center environment is imperative. With historical temperature data, accurate CFD simulation is achieved. It can be relayed to a cloud CFD platform upon collecting temperature data. Once in the platform, the more extensive the data, the more simulations. Predicting scenarios is precise, for that matter, as sensors provide accurate readings.

AKCP wired, and wireless sensors are effective solutions in a wide range of industries. AKCP wireless sensors can address the necessary monitoring objectives in a data center operation. The sensors that are most relevant to provide direct help to CFD modeling are:

- Temperature Monitoring Sensors

- Remote Site Sensors

- Power Monitoring Sensors

- Environmental Monitoring Sensors

An AKCP wireless temperature sensor is calibrated and works as pair. This is designed to check on each other’s values once a second to maintain accuracy. When sensors are beyond the acceptable thresholds, an alert can be sent. Datacenter engineers have now notification to recalibrate the sensor as necessary. As they work in pairs, the average of each pair is again averaged. This results in the overall reading. What it does is improve accuracy.

AKCP wireless AC voltage sensor can monitor circuits. Checking circuits if they are energized is a fundamental power monitoring capacity that can aid CFD modeling on energy simulation. The sensor can detect the presence or absence of AC voltage.

Having these monitoring means a much-improved accuracy for CFD simulation. Providing close to real-life scenarios raises better action steps in risk management. Thus, negating harmful threats brought about by temperature and airflow fluctuations.

Reaping The Benefits Of Energy Simulation

The value of CFD analysis for data center energy simulation adheres to preprogrammed objectives to address a problem. Simulation can answer a general problem, but it can also best tackle the more specific ones. Providing particular prerequisites enable CFD models to zero in on areas to check. A few of the examples include:

- Specification of different air supply and ambient temperatures in an existing server layout.

- Comparison of physical distinctions such as aisle width, server size, and air vent distances.

- Distinguishing energy flow from the power source to the server.

- Mapping the flow pattern of air to check air distribution channels.

Some data center managers may misconstrue simulations to more grant operational investment. That is not entirely the case. Simulation can be done on the most fundamental problems to address. As simple as temperature plotting to check IT surfaces is a substantial step to energy reduction, for example. This kind of aid encapsulates the many fundamental data center problems and can be run as a standalone simulation. The best part is, they can also be viewed as a comprehensive scenario. Having that visibility qualifies the interconnectedness of actions to mitigate the many problems accounted for in the simulation.

Energy simulation in a data center has increasingly raised its importance. Notably, its preventive scenario building provides better data center performance. As such, specific CFD simulations pave the way for more understanding of the data center ecosystem from multiple points of view. The different configurations of CFD models provide this.

It is important to note that these simulations should run their course to evaluate the data center thoroughly. Energy simulation cannot be justified by predicting possible system performance alone. It is incomplete utilization of this critical information where valuable impacts happen. Integrating sound monitoring complementing your CFD simulations is a powerful combination to foolproof your future data center.

Reference Links:

https://www.datacenterdynamics.com/en/opinions/why-simulate-data-centers/

https://www.femto.eu/stories/what-is-cfd/