While the demand for cloud-based services heightens, data centers are becoming notorious for the amount of energy they consume. High-density racks are servicing manufacturing, online gaming, on-demand IP-based TV, must streaming, and social media. Data centers’ energy use is predicted to grow from 200 TWh in 2016 to 2,967 TWh in 2030. Consequently, administrators are called to rethink and create a sustainable design.

“Net-Zero Data Centres are the next generation of sustainable data centers. Forming the basis of clean energy infrastructure that is resilient, sustainable, and safe” as stated by the United Nations Sustainable Development Goal. This can be achieved with renewable energy in lieu of conventional solutions. Resources like wind, sun, and bio-gas are used as the primary power source in data center operation. The integration of waste heat recovery systems or recycled water with evaporative cooling equipment leads the way to sustainability. For example, the HP Net-Zero Energy Data Center cuts off its dependence on grid power by more than 80% while running the business as usual.

Carbon Free Energy (CFE) Data Center Design

Photo Credit: datacenterfrontier.com

Net-Zero Data Centers use carbon-free energy on-premise for continuous operation even without utility grid power. One of the enterprises that leverage this innovative solution is Microsoft. Since 2017, it has been operating its Seattle data center using carbon-free energy. According to Sean James, director of Energy Research, the data center has been long-running without experiencing any outage using fuel cells. This design connects the fuel cells to the natural gas distribution. It generates reliable power that can follow the power demand of the data center at any location. Therefore, the overall power supply within the facility will not be affected by a failure of a single fuel cell. Not only is it a sustainable solution, but it is also more cost-effective than using the grid power supply. It takes advantage of the low-cost fossil fuel generation in most of the countries in the world.

Scheduling on a CFE Data Center Design

Carbon-free energy consumption is highly related to resource availability. With the variable amount of power available at each moment, scheduling on this design is critical. This ensures that there are enough resources to complete a running task. Scheduling can be based on batch tasks. These are characterized by their release time, due date, and resource demand. For example, solar panels produce extra power when the sun is out. So, solar-powered data centers can schedule a heavy workload during the day. Then non-critical works can take place at night when solar supplies are unavailable.

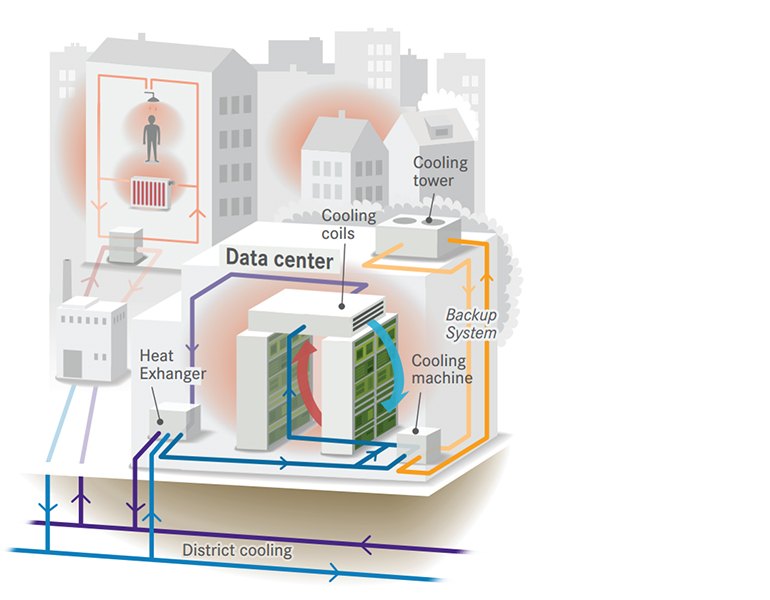

Liquid Cooling to a Net-Zero Data Center Design

Air cooling has been the top-of-the-mind cooling solution in most data centers. But today, adding water appears indistinctly as an alternative solution. It started to dominate the market addressing challenges of the rising electricity and environmental impact. The data centers in Europe and North America recently mandated a “liquid ready” design for current and future data centers. This comes as no surprise as water’s capacity for removing heat is 50 to 1,000 times greater than air. With water, air cooling can be a viable solution. It prevents hotspots and other heat-related issues more effectively. For instance, Computer Room Air Handling (CRAH) and fans can be cool servers with chilled water through an indirect evaporative cooling system. This can cool up to 10-kW racks in the data hall. In addition, a study revealed that upgrading with a rear door exchanger can deliver 50% more cooling. Despite knowing the disastrous combination of electricity and water, this capacity pushed the operators to take the risk.

Indirect Evaporative Liquid Cooling

Photo Credit: snopud.bizenergyadvisor.com

Indirect evaporative liquid cooling eliminates energy-intensive liquid cooling equipment such as compressors and chillers. This paves the way in achieving a Net-Zero Energy data center. This works the same as direct evaporative liquid cooling, lowering the air temperature through water evaporation. However, in this solution, a heat exchanger is required.

Two opposing air streams contact a different side of a heat exchanger. The first stream is called the primary air that is being cooled down. The second stream is usually called the atmospheric air. It functions by removing the heat from the primary air. The air is carried through ventilation to cool the indoor temperature without mixing two air streams. The hot outside air will pass through a heat exchanger to which cold water is supplied. The heat is removed as it runs through these series of metal tubes. The cool and dry air will be then delivered into the server room. This method is ideal for locations where gaining extra humidity is not desirable.

The Benefits of Indirect Evaporative Liquid Cooling

There are several reasons why indirect evaporative cooling should be considered. These are also used in weighing up this alternative in redesigning a Net-Zero Energy data center.

-

Less Water Need

Indirect evaporative liquid cooling has a significant contribution to water savings. Through recycled wastewater, it uses approximately 50% less water in cooling the facility. The wastewater is treated using chemicals to prevent microbial growth. It will be then pumped into the data center space through an underground piping system. Google is currently using recycled water in its data center in Atlanta. It also collaborated with the municipality to ensure that its operation does not surpass the available supply on the local sewer system.

-

Energy Efficiency

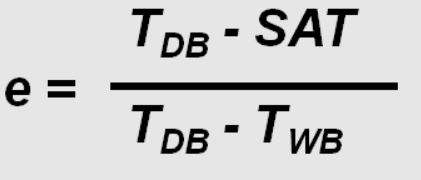

Energy efficiency is one of the strongest factors that pull operators into indirect evaporative liquid cooling. According to ASHRAE heat exchangers are proven to lower energy consumption by 50%. As it cools the air without increasing humidity, it can lower the temperature of the dry-bulb and wet-bulb temperature without the use of compressors. Also, the evaporative cooling equipment which the air passes has 90% efficiency.

Calculating the Evaporative Effectiveness (EF) determines the temperature delivered by the evaporative cooling equipment. Usually, the EF of evaporative cooling equipment reaches 75%. . I can be calculated as:

Photo Credit: basc.pnnl.gov

-

Greener Solution

This solution uses free cooling properties such as water that reduces carbon footprint. Energy consumption of data centers will contribute up to 3.2% of the global carbon emissions by 2025. The main reason is the huge computer room air conditioning units. They consume massive amounts of energy emitting more carbon footprint. With the indirect evaporative cooling method, data center cooling will have little to no reliance on this system. This will yield a significant impact on the environment if implemented by most of the data centers in the world.

-

Cost-Effective

Datacenter cooling accounts for about 40% of the operating cost. This is equivalent to millions of dollars as electricity costs continue to rise every year. Indirect evaporative liquid cooling cut this cost by more than half. More than the savings on energy cost, it also has a more competitive installation cost. Evaporative coolers can be easily installed in the air handling units. It also requires lower maintenance costs making it a cost-effective long-term solution.

-

Reduced Risk of Water Leak

Indirect evaporative cooling allows for data center cooling without extra air moisture. Also, the cooled air never comes in direct contact with the conditioned air. This mitigates the risk of corrosion, mold growth, and water leak. Datacenter safe from whatever possible occurrence related to water causing downtime.

How Do Sensors Work?

Photo Credit: toptechengineeringltd.com

Designing a Net-Zero Energy Data Center requires direct day-to-day management. This will grow to the environmental awareness of the operators. Monitoring temperature and humidity are incredibly important. It ensures that the data center is operating in an optimum environment. The innovation of automated sensors is now exploited in the industry. Operators gain analytics as a basis for decision-making. It collects real-time data allowing them to be aware of the present and predict the oncoming issues in the future.

For indirect evaporative liquid cooling, temperature and relative humidity are measured. Specifically, on different points within the fresh air handling unit for each mode of operation. The efficiency effectiveness (EF) which is mentioned before is evaluated based on the temperature difference across the heat exchanger and dry and wet bulb. Humidity must also be kept at 60-80% as recommended by ASHRAE.

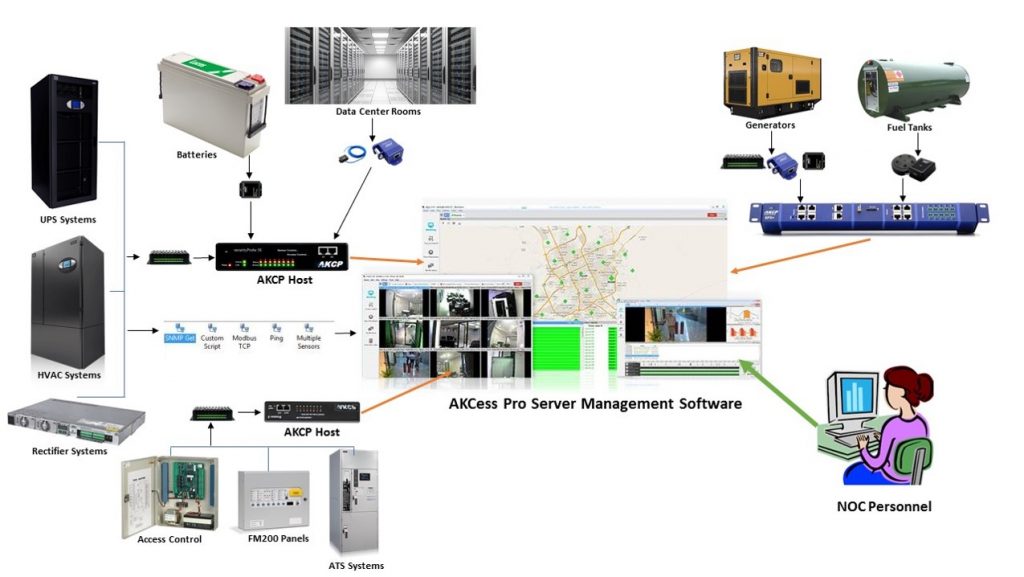

Monitoring with AKCP

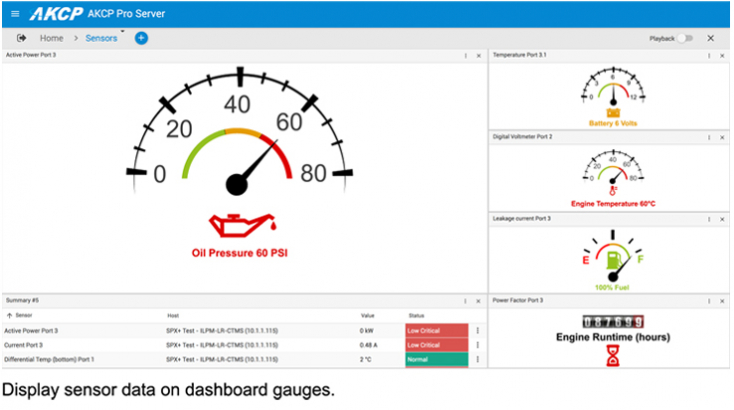

AKCPro Server

AKCPro Server is our world-class central monitoring and management software. Suitable for a wide range of monitoring applications. Free to use for all AKCP devices. Monitor your infrastructure, whether it be a single building or remote sites over a wide geographic area. Integrate third-party devices with, Modbus, SNMP, and ONVIF compatible IP cameras.

All deployed AKCP base units and attached sensors can be configured and monitored from AKCPro Server (APS). Base units communicate with the server through your wired local network (LAN) or wide area network (WAN). Remote sites with no wired network send data to the server through the cellular data network* via a VPN connection.

AKCPro Server Central Monitoring Software

Integrated monitoring of all devices

AKCPro Server integrates all your environmental, security, power, access control, and video in a single, easy-to-use software.

Environmental Monitoring

Monitor all your temperature, humidity, airflow, water leak, and other environmental sensors. Configure rack maps to show the thermal properties of your computer cabinet, check the temperature at the top, middle, bottom, front, and rear, as well as temperature differentials.

Security Monitoring

Ensure that your facilities and critical infrastructure are secured. Door contact sensors, audible and visual alarms are configured and managed from your custom desktops in APS.

Power Monitoring

Monitor single-phase, three-phase, generators, and UPS battery backup power. AKCP Pro Server performs live Power Usage effectiveness (PUE) calculations so you have a complete overview of your power train and how adjustments in your data center directly impact your PUE.

Access Control

AKCPro Server is used to administer the access rights and schedules for all AKCP Door Control, Cabinet Control, and RFID Cabinet locks. Secure your assets, control access, and generate reports to give a complete audited trail of access.

Video Monitoring

Video feeds from Integrated ONVIF compatible IP cameras and cameras connected to AKCP securityProbe base units can be monitored and recorded in AKCPro Server. Synchronize sensor events with video in the playback window for an “eyes on” to any sensor events.

Reference Links:

www.un.org/sustainabledevelopment/cities/

www.hp.com/us-en/hp-information/social-innovation/hp-net-zero-energy-data.html#.YPv_U44zY2w

newbuildings.org/wp-content/uploads/2015/11/IEC_ZNE_TAG2.pdf?fbclid=IwAR3xXFJ0DfVWhqZGWcoY8CyzJWiRiJAgqAnQNZ5vuLrTMDh6intPBSO3knw

www.computerworld.com/article/3431148/why-data-centres-are-the-new-frontier-in-the-fight-against-climate-change.html

www.techerati.com/features-hub/opinions/simultaneously-resilient-and-sustainable-net-zero-data-centres/

sada.com/insights/blog/sustainability-and-carbon-free-transparency-with-google-cloud/